Einführung zur Produktleistung

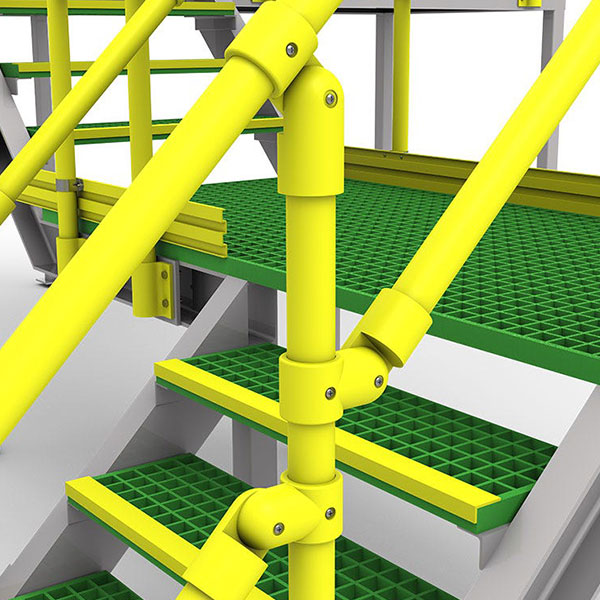

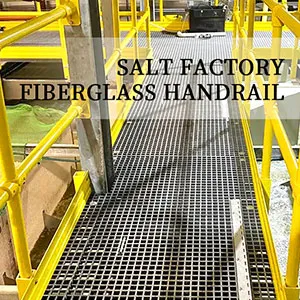

Geländer und Handläufe aus GFK (glasfaserverstärktem Kunststoff) Es handelt sich um moderne Sicherheitslösungen, die für industrielle und gewerbliche Anwendungen entwickelt wurden, bei denen Korrosionsbeständigkeit, Langlebigkeit und langfristige strukturelle Integrität erforderlich sind. Diese Systeme bieten Schutzbarrieren entlang von Gehwegen, Plattformen, Treppen, Zwischengeschossen und Dachzugangsbereichen, um Unfälle durch Stürze zu verhindern und die Sicherheit des Personals zu gewährleisten.

Materielle Vorteile

Der Hauptvorteil von GFK-Geländern und Handläufen liegt in ihrer Verbundstruktur, Sie bestehen typischerweise aus einer Matrix aus Harz (wie Vinylester, Isophthalpolyester oder Epoxidharz) und Glasfaserverstärkung. Diese einzigartige Kombination bietet im Vergleich zu herkömmlichen Stahl- oder Aluminiumsystemen mehrere überlegene Materialeigenschaften:

- KorrosionsbeständigkeitGFK rostet und zersetzt sich nicht bei Kontakt mit Wasser, Salznebel, Chemikalien oder industriellen Schadstoffen. Es ist ideal für anspruchsvolle Umgebungen wie Hafenanlagen, Kläranlagen und chemische Produktionsanlagen.

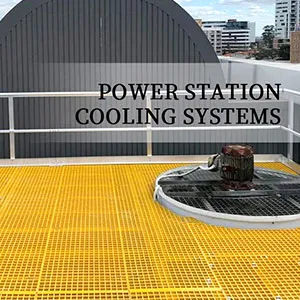

- Nicht leitendGFK ist elektrisch isolierend und daher in Bereichen, in denen die Gefahr des Kontakts mit elektrischen Systemen besteht, sicherer als Metall.

- Leicht und dennoch robustFaserverstärkte Kunststoffkonstruktionen bieten ein hohes Festigkeits-Gewichts-Verhältnis, was bedeutet, dass sie einfacher zu handhaben und zu installieren sind, ohne die strukturelle Festigkeit zu beeinträchtigen.

- UV- und witterungsbeständigMit geeigneten Harzsystemen und Beschichtungen behalten GFK-Handläufe auch bei längerer Sonneneinstrahlung und unter Witterungseinflüssen ihre Farbe und mechanische Integrität.

- Geringer WartungsaufwandIm Gegensatz zu Metall, das regelmäßig gestrichen oder verzinkt werden muss, benötigen GFK-Handläufe während ihrer gesamten Lebensdauer nur minimalen Wartungsaufwand.

Design & Konfiguration

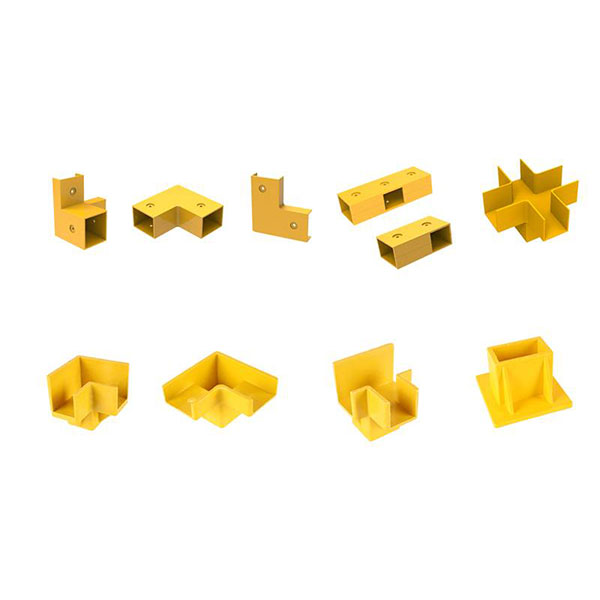

GFK-Leitplankensysteme können hergestellt werden in modulare, vorgefertigte Abschnitte, Dies ermöglicht eine schnelle und einfache Installation. Gängige Konfigurationen umfassen:

- Zwei- und Dreischienensysteme

- Zehenplatten oder Trittplatten für zusätzlichen Fußschutz

- Pfosten- und Riegelkonstruktionen mit anpassbarem Abstand und Höhe

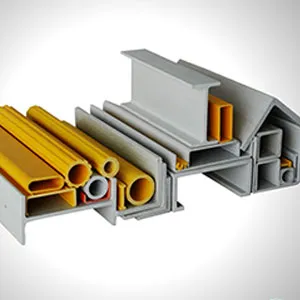

- Quadratische oder runde Rohrprofile

- Benutzerdefinierte Farben erhältlich, typischerweise in Gelb oder Grau für hohe Sichtbarkeit

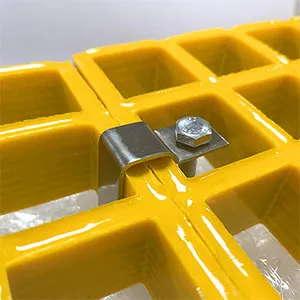

Alle Verbindungen und Armaturen sind chemisch gebunden oder mechanisch mit GFK- oder Edelstahlbeschlägen befestigt, um eine langfristige Haltbarkeit zu gewährleisten.

Spezifikationen und technische Parameter für GFK-Geländer und Handläufe

1. Materialzusammensetzung

- Harzarten:

- Isophthal-Polyesterharz (Standard-Industrieanwendung)

- Vinylesterharz (für stark korrosive Umgebungen)

- Phenolharz (für feuerbeständige und raucharme Anwendungen)

- Verstärkung:

- Endlos-Glasfaserrovings und -matten für Festigkeit und Haltbarkeit

2. Mechanische Eigenschaften

| Eigentum | Typischer Wert |

|---|---|

| Zugfestigkeit | ≥ 200 MPa |

| Biegefestigkeit | ≥ 300 MPa |

| Druckfestigkeit | ≥ 250 MPa |

| Elastizitätsmodul (Biegemodul) | 20–30 GPa |

| Schlagfestigkeit (Kerbschlagzähigkeit nach Izod) | ≥ 90 J/m |

3. Physikalische Eigenschaften

| Eigentum | Typischer Wert |

|---|---|

| Dichte | 1,7 – 2,0 g/cm³ |

| Wasseraufnahme (24h) | < 0,5% |

| Wärmeleitfähigkeit | ~0,3 W/m·K |

| Betriebstemperaturbereich | -40 °C bis +120 °C (bis zu 180 °C für Spezialharze) |

| Feuerbeständigkeit (ASTM E84) | Flammenausbreitungsindex ≤ 25 (Klasse I) |

4. Elektrische Eigenschaften

| Eigentum | Typischer Wert |

|---|---|

| Durchschlagsfestigkeit | ≥ 25 kV/mm |

| Oberflächenwiderstand | > 10¹² Ohm |

| Volumenwiderstand | > 10¹³ Ohm·cm |

| Lichtbogenbeständigkeit | Exzellent |

5. Abmessungen

| Komponente | Standardgröße (mm) |

|---|---|

| Vertikale Pfosten | 50 × 50 mm oder 60 × 60 mm Vierkantrohr |

| Horizontale Schienen | 50 × 50 mm oder 38 mm Rundrohr |

| Pfostenabstand | 1000 mm (Mitte zu Mitte) |

| Pfostenhöhe | 1100–1200 mm |

| Zehenschutzplatte (optional) | 100 mm Höhe × 4–6 mm Dicke |

Sondergrößen und -konfigurationen sind auf Anfrage erhältlich.

6. Oberflächenbeschaffenheit

- Standard: Glatte oder rutschfeste, geschliffene Oberfläche

- Beschichtung: UV-beständiger Decklack oder pigmentiertes Harz

- Farbe: Typischerweise gelb oder grau (kundenspezifische RAL-Farben auf Anfrage)

7. Installationsoptionen

- Grundplattenmontage (mit Edelstahlbolzen verankert)

- Seitliche Montagehalterungen

- Eingebaute Pfostenmontage

8. Standards und Konformität

- OSHA 1910.29 (Leitplankensysteme)

- ASTM E84 (Flammenausbreitung)

- ISO 14122-3 (Maschinensicherheit – dauerhafte Zugangsmöglichkeiten)

- EN 14122 & BS 6399 (Normen für die Tragwerksplanung)

Warum Sie sich für uns entscheiden sollten

Fachkompetenz in der Herstellung von GFK-Gitterrosten

Mit über 20 Jahren Erfahrung ist unser Werk auf die Entwicklung und Produktion von Hochleistungs-Gitterrosten aus glasfaserverstärktem Kunststoff (GFK) spezialisiert. Dank unserer umfassenden Branchenkenntnisse erfüllt jedes Produkt höchste Industriestandards.

Fortschrittliche Technologie und Ausrüstung

Wir nutzen modernste Fertigungsanlagen und Präzisionsformtechnik, um Gitterroste mit höchster Festigkeit, Korrosionsbeständigkeit und Maßgenauigkeit herzustellen. Dank unseres Innovationsanspruchs profitiert Ihr Projekt von den neuesten Fortschritten in der Faserverbundtechnologie.

Maßgeschneiderte Lösungen

Von Plattengrößen und Harzarten bis hin zu Oberflächenbeschaffenheiten und Farben bieten wir Ihnen eine umfassende Anpassung, um Ihren individuellen Anwendungsanforderungen gerecht zu werden – sei es bei Industrieböden, Treppenstufen, Grabenabdeckungen oder Schiffsplattformen.

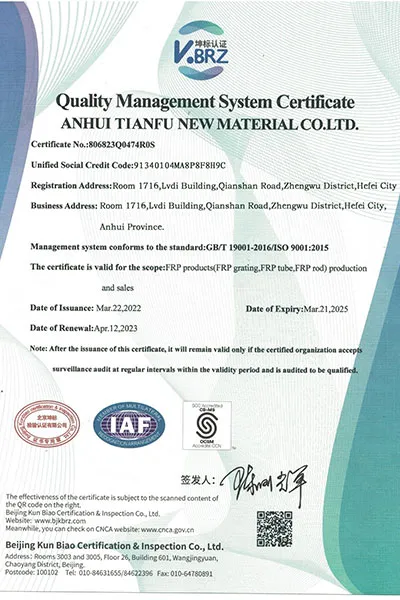

Strenge Qualitätskontrolle

Jedes Produkt durchläuft einen strengen Qualitätsprüfungsprozess, der Belastungstests, Prüfungen der Flammwidrigkeit und Korrosionsbeständigkeitsanalysen umfasst. Unser ISO-zertifiziertes Qualitätsmanagementsystem gewährleistet gleichbleibend hohe Qualität in jeder Charge.

Wettbewerbsfähige Preise

Wir bieten Preise direkt ab Werk ohne Kompromisse bei der Qualität. Dank optimierter Produktionsprozesse und unserer Kapazitäten zur Massenfertigung unterstützen wir unsere Kunden dabei, Kosteneinsparungen in großem Umfang zu erzielen.

Zuverlässige Lieferung und globale Reichweite

Wir halten ein umfangreiches Sortiment an Standardprodukten vor und betreiben ein effizientes Logistiksystem, das schnelle Lieferzeiten im In- und Ausland gewährleistet. Wir haben bereits Kunden in über 15 Ländern erfolgreich betreut.

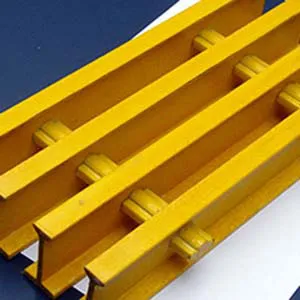

Verkaufsschlager

| Standard-Paneelgrößen | 1220 mm × 3660 mm (4 Fuß × 12 Fuß) 1220 mm × 4000 mm (4 ft × 13,1 ft) 915 mm × 3050 mm (3 Fuß × 10 Fuß) 1000 mm × 3000 mm (anpassbar) (Andere Größen können je nach Projektbedarf angepasst werden.) |

| Dickenoptionen | 25 mm (1 Zoll) 30 mm (1,2 Zoll) 38 mm (1,5 Zoll) – am häufigsten 50 mm (2 Zoll) |

| Maschenweite (Öffnungsgröße) | 38 mm × 38 mm (1,5 Zoll × 1,5 Zoll) — Standard 40 mm × 40 mm 19 mm × 19 mm (Mini-Maschengewebe zur Verhinderung des Durchtritts kleiner Gegenstände) |

| Laststangenbreite und -abstand (für pultrudierte Gitterroste) | Laststangenbreite: typischerweise 25 mm, 38 mm, 50 mm Laststababstand: 25 mm, 40 mm, 50 mm (Mitte zu Mitte) |

| Oberflächenoptionen | Geriffelte Oberfläche (rutschfest) Glatte Oberfläche Bedeckte Oberfläche (massive Oberseite) |

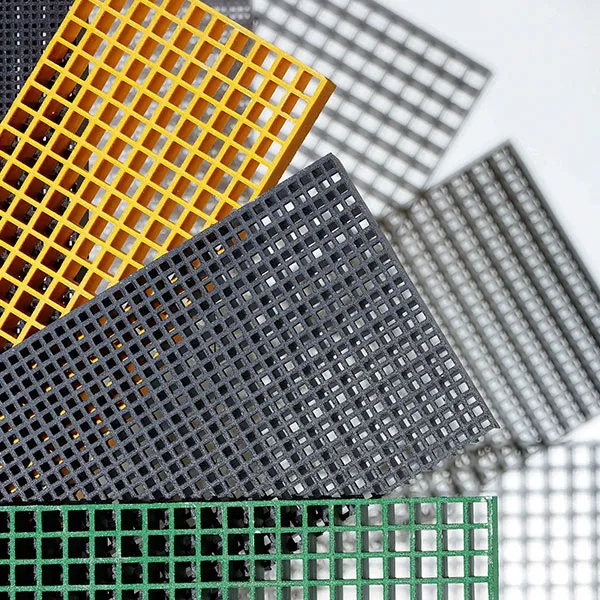

| Verfügbare Farben | Gelb (am häufigsten) Grün Grau Rot Individuelle Farben auf Anfrage |

| Gängige Harzarten | Isophthal-Polyester (Standardkorrosionsbeständigkeit) Vinylester (hohe Chemikalienbeständigkeit) Phenolharz (feuerbeständige Anwendungen) |

Über das Werk

Anhui Tianfu New Material Co., Ltd ist ein führender professioneller Hersteller, der sich auf GFK-Formgitter Produktion. Mit über 20 Jahren Erfahrung in der Verbundwerkstoffindustrie bieten wir hochwertige Lösungen aus glasfaserverstärktem Kunststoff (GFK) für vielfältige industrielle und gewerbliche Anwendungen. Unsere moderne Fabrik mit fortschrittlichen Produktionslinien erstreckt sich über eine Fläche von mehr als 26.000 Quadratmetern. Wir bieten ein umfassendes Sortiment an GFK-Formrosten mit überlegener Festigkeit, Chemikalienbeständigkeit, Feuerbeständigkeit und Rutschfestigkeit. Bei Tianfu New Material stehen Innovation, strenge Qualitätskontrolle und Kundenzufriedenheit an erster Stelle. Unsere Produkte sind nach internationalen Standards zertifiziert und werden in über 30 Länder weltweit exportiert. Sie kommen unter anderem in Chemieanlagen, Kläranlagen, Offshore-Plattformen und im Bereich Laufstege zum Einsatz. Ob Standardgrößen oder kundenspezifische Lösungen – Tianfu ist Ihr zuverlässiger Partner für GFK-Formroste.

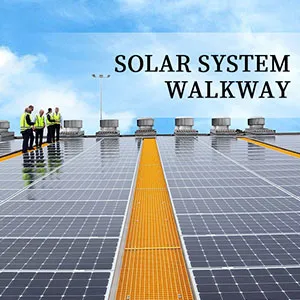

Anwendungsszenarien

Über das Werk

Wir sind ein professioneller Hersteller von GFK-Gitterrosten mit über 20 Jahren Erfahrung. Unser 26.000 m² großes Werk ist ISO 9001-zertifiziert und beliefert Kunden in über 30 Ländern mit OEM/ODM-Fertigungskapazitäten. Wir bieten maßgeschneiderte Lösungen und schnelle Lieferung weltweit.

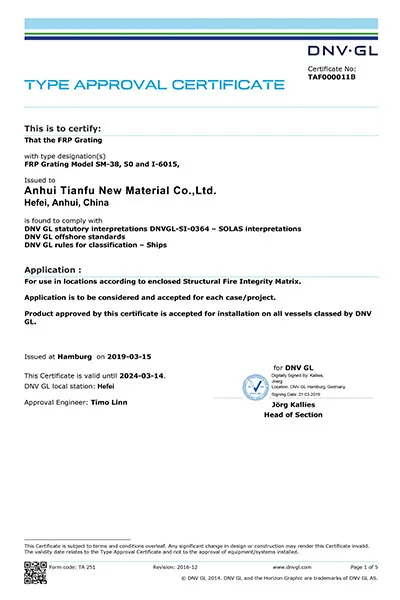

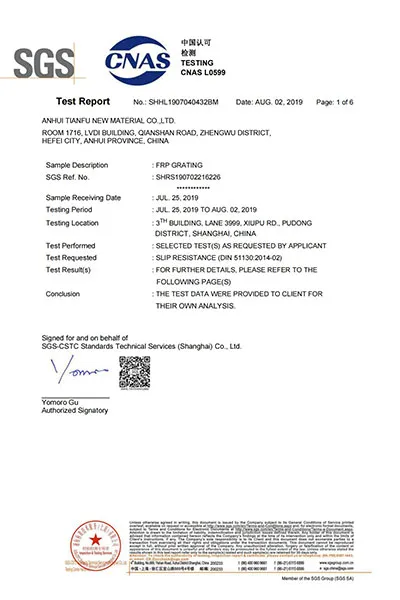

Unsere GFK-Gitterroste werden gemäß ISO 9001 gefertigt und nach ASTM E84 (Brandschutzklasse 1) sowie ASTM D638/D790 (mechanische Eigenschaften) geprüft. Sie entsprechen den Normen BS 476 und EN 13706. Prüfungen durch Dritte (SGS und TÜV) sind auf Anfrage möglich.

Ausstellung

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

Zertifikat

Andere Produkte

VR-Werksführung

FRP-Schutzgeländer und Handläufe

Serie :

Fiberglas-Handlaufsystem >Anwendung

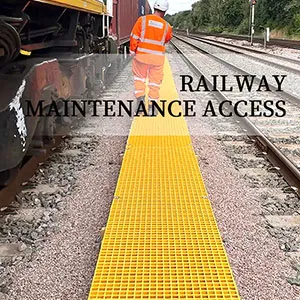

Industrieanlagen (Chemie, Öl & Gas, Energieerzeugung), Abwasser- und Wasseraufbereitungsanlagen, Bergbau- und Hüttenbetriebe, maritime und Offshore-Plattformen, Lebensmittel- und Getränkeverarbeitung, öffentliche Infrastruktur (Brücken, Fußgängerwege, Eisenbahnen), Reinräume und pharmazeutische Anlagen

Zugfestigkeit :

≥ 200 MPa

Biegefestigkeit:

≥ 300 MPa

Druckfestigkeit:

≥ 250 MPa

Elastizitätsmodul (Biegemodul):

20–30 GPa

Schlagfestigkeit (Kerbschlagzähigkeit nach Izod):

≥ 90 J/m

FAQ

Q :

Wozu werden GFK-Geländer und Handläufe verwendet?

A :

FRP-Schutzgeländer und Handläufe werden als Sicherheitsbarrieren auf Gehwegen, Treppen, Plattformen und erhöhten Arbeitsbereichen eingesetzt, um Stürze zu verhindern und den Schutz des Personals in korrosiven, nassen oder gefährlichen Umgebungen zu gewährleisten.

Q :

Wie schneiden GFK-Schutzplanken im Vergleich zu Stahl- oder Aluminiumsystemen ab?

A :

Faserverstärkte Kunststoffsysteme (FVK) sind korrosionsbeständig, nichtleitend, leicht und wartungsärmer als Stahl oder Aluminium. Sie eignen sich ideal für den Langzeiteinsatz in anspruchsvollen Industrie- oder Schiffsumgebungen.

Q :

Sind Handläufe aus GFK für den Außenbereich geeignet?

A :

Ja, GFK-Handläufe sind UV-beständig, witterungsbeständig und so konstruiert, dass sie Witterungseinflüssen wie Regen, Salznebel und Temperaturschwankungen standhalten.

Q :

Können GFK-Schutzgeländer individuell angepasst werden?

A :

Absolut. FRP-Schutzgeländer können hinsichtlich Höhe, Geländerabstand, Farbe und Anordnung individuell angepasst werden, um den spezifischen Gegebenheiten vor Ort und den geltenden Normen gerecht zu werden.

Q :

Welchen Normen entsprechen GFK-Schutzgeländer?

A :

Die meisten GFK-Handlaufsysteme erfüllen, sofern erforderlich, die Anforderungen der OSHA 1910.29, ISO 14122-3 und ASTM E84 hinsichtlich der Feuerbeständigkeit.

Q :

Sind GFK-Handläufe schwierig zu montieren?

A :

Nein. GFK-Systeme sind modular, leicht und oft vorgefertigt. Sie lassen sich problemlos vor Ort mit Standardwerkzeugen montieren, was Arbeitszeit und Kosten reduziert.

Q :

Benötigen GFK-Leitplanken regelmäßige Wartung?

A :

Der Wartungsaufwand ist minimal. Im Gegensatz zu Metall rostet GFK nicht und muss nicht neu lackiert werden. Gelegentliche Reinigung und Inspektion genügen in der Regel.

Andere verwandte Produkte