Produsen Kisi-kisi FRP Tianfu

Kisi-kisi FRP

Produsen Tianfu->

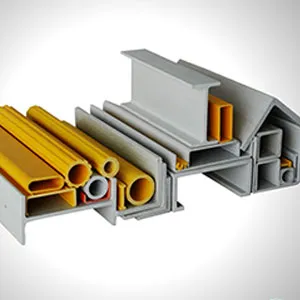

Kisi-kisi Fiberglass adalah material struktural yang menggunakan serat kaca sebagai material penguat dan resin poliester tak jenuh sebagai matriks, dan dikompositkan melalui pencetakan atau pultrusi. Material ini menggabungkan kekuatan tinggi serat kaca dan ketahanan korosi resin, serta memiliki kinerja yang baik dalam hal kekuatan, ketangguhan, ketahanan korosi, isolasi, dan ketahanan terhadap penuaan. Dibandingkan dengan kisi-kisi baja atau kayu tradisional, kisi-kisi FRP tidak hanya ringan, mudah dibawa, dan mudah dipasang, tetapi juga tidak memerlukan perawatan rutin, memiliki masa pakai yang lebih lama, dan memiliki manfaat ekonomi yang signifikan.

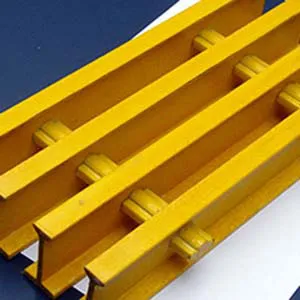

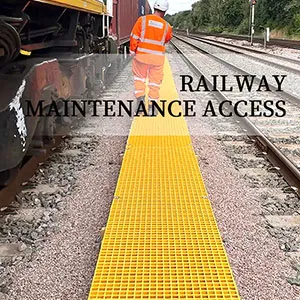

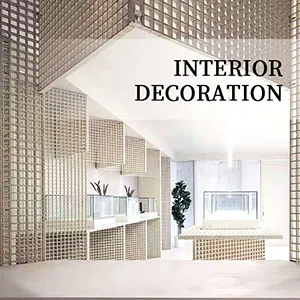

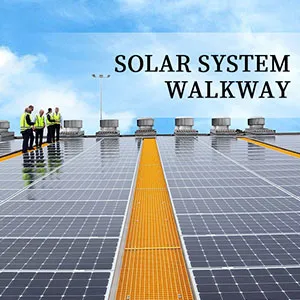

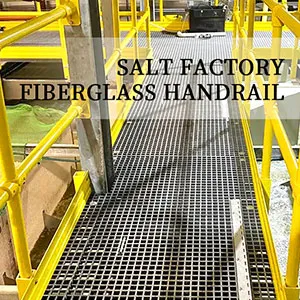

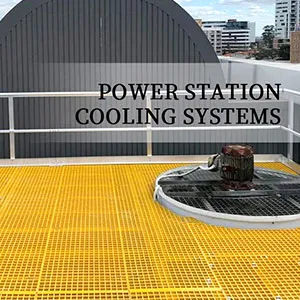

Kisi-kisi FRP banyak digunakan di bidang petrokimia, bengkel pelapisan listrik, instalasi pengolahan air, anjungan lepas pantai, pembuatan kapal, metalurgi, kelistrikan, tekstil, pengolahan makanan, dan bidang lainnya, terutama pada anjungan operasi, jalan setapak, anak tangga, penutup talang, dll. di lingkungan korosif. Permukaan produk dapat diberi perlakuan anti-selip berupa pasir atau cembung untuk meningkatkan keamanan. Sesuai dengan berbagai skenario dan persyaratan beban, kisi-kisi FRP dapat disesuaikan dengan berbagai ukuran jala, ketebalan, warna, dan jenis resin (seperti ortoftalik, isoftalik, vinil, dll.).

Selain itu, kisi-kisi FRP memiliki sifat isolasi listrik dan isolasi termal yang baik, tidak menghantarkan listrik dan tidak menghantarkan panas, dan sangat cocok untuk tempat-tempat dengan persyaratan keselamatan tinggi, seperti pembangkit listrik dan platform kerja di ketinggian. Karena tidak mengandung komponen logam, kisi-kisi ini tidak akan menyebabkan korosi elektrokimia dan tidak akan mengganggu pengoperasian instrumen dan peralatan. Sebagai jenis material komposit ramah lingkungan yang baru, kisi-kisi FRP tidak hanya dapat meningkatkan efisiensi operasional fasilitas industri, tetapi juga menghemat banyak biaya perawatan untuk pabrik. Ini adalah salah satu pilihan material struktural yang ideal untuk infrastruktur industri modern.

1. Mengapa Memilih Kami?

1) Pengalaman manufaktur profesional

Tianfu New Materials telah fokus pada bidang kisi-kisi FRP selama bertahun-tahun dan memiliki lini produksi yang matang serta pengalaman industri yang kaya. Mulai dari pengadaan bahan baku, desain produk, pengembangan cetakan hingga produksi massal, terdapat kontrol ketat untuk memastikan kualitas produk yang stabil dan andal.

2) Jaminan kualitas produk

Dengan menggunakan serat kaca berkekuatan tinggi dan resin poliester tak jenuh berkualitas tinggi, dikombinasikan dengan teknologi pencetakan atau pultrusi canggih, pelat kisi-kisi ini memiliki ketahanan korosi, kapasitas menahan beban, anti selip, dan ketahanan cuaca yang sangat baik, serta memenuhi standar kualitas internasional (seperti ASTM, ISO).

3) Layanan kustomisasi yang beragam

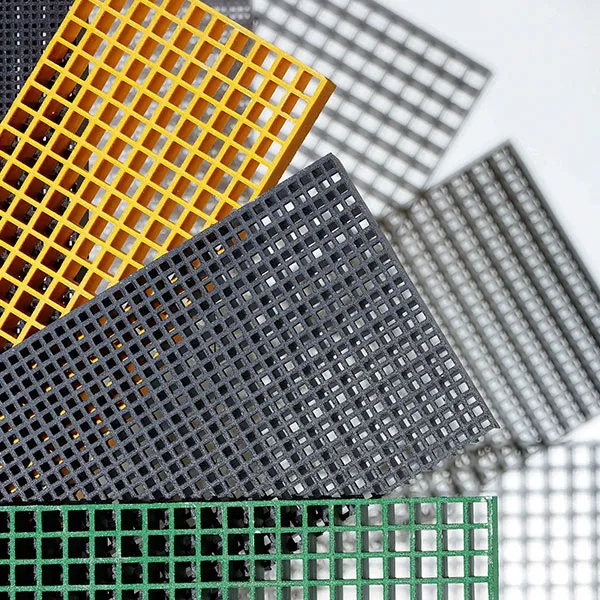

Menyediakan pilihan produk dengan berbagai spesifikasi, warna, dan sistem resin (o-ftalat, isoftalat, dan vinil) untuk memenuhi kebutuhan personalisasi pelanggan di berbagai industri. Pada saat yang sama, mendukung kustomisasi gambar dan layanan OEM untuk menyesuaikan solusi terbaik bagi proyek-proyek teknik.

4) Kemampuan pengiriman cepat

Pabrik ini berskala besar, dengan persediaan yang cukup, dan memiliki kemampuan untuk merespons pesanan dengan cepat guna memastikan bahwa kemajuan proyek pelanggan tidak terganggu. Untuk model konvensional, layanan pengiriman cepat dapat disediakan.

5) Pengalaman ekspor dan layanan internasional

Tianfu New Materials memiliki pengalaman yang kaya dalam perdagangan internasional. Produk-produknya diekspor ke banyak negara dan wilayah seperti Eropa, Amerika, Timur Tengah, dan Asia Tenggara. Perusahaan ini mendukung komunikasi multibahasa, pengemasan dan pengaturan logistik standar internasional, dan merupakan mitra luar negeri yang dapat dipercaya.

6) Layanan purna jual berkualitas tinggi

Mulai dari konsultasi teknis pra-penjualan, saran pemilihan produk hingga panduan teknis purna-penjualan dan penanganan masalah, tim Tianfu menyediakan dukungan layanan lengkap untuk memastikan pelanggan dapat menggunakannya tanpa khawatir.

2. Produk Terlaris

| Barang | Nilai Khas | Keterangan |

|---|---|---|

| Bahan | Resin poliester tak jenuh + serat kaca | Tersedia dalam bentuk ortoftalat, isoftalat, dan vinil ester. |

| Proses Pembuatan | Pencetakan / Pultrusi | Tergantung pada spesifikasi produk |

| Kepadatan | 1,8 – 2,0 g/cm³ | Ringan, mudah ditangani |

| Daya tarik | ≥ 200 MPa | Kekuatan mekanik tinggi |

| Kekuatan Lentur | ≥ 250 MPa | Kapasitas menahan beban yang baik |

| Modulus Lentur | ≥ 6000 MPa | Kaku dan tahan lama |

| Kekuatan Geser | ≥ 70 MPa | Ikatan internal yang tinggi |

| Kekerasan Barcol | ≥ 40 | Ketahanan aus permukaan |

| Suhu Operasional | -40℃ ~ +120℃ | Cocok untuk lingkungan yang keras |

| Tahan korosi | Bagus sekali | Tahan terhadap lingkungan asam, basa, dan garam. |

| Isolasi Listrik | Bagus sekali | Tidak menghantarkan listrik, aman untuk area listrik. |

| Ketahanan Selip | R13 (dengan permukaan bertekstur kasar) | Tersedia pilihan permukaan anti selip. |

| Tahan Api | Opsional | Tersedia standar ASTM E84 Kelas 1 atau EN 13501. |

| Warna Standar | Kuning, Hijau, Abu-abu, Biru, Kustom | Tersedia warna tahan UV. |

| Ukuran Jala | 25×100mm, 38×38mm, 50×50mm, dll. | Ukuran khusus tersedia berdasarkan permintaan. |

| Opsi Ketebalan | Ukuran umum: 25mm, 38mm, 50mm | Ketebalan lain dapat disesuaikan. |

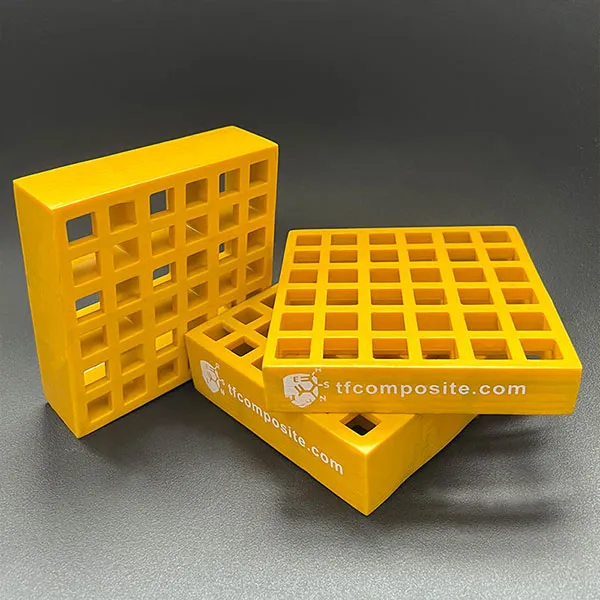

Berbagai Gaya Kisi-kisi Fiberglass

3. Skenario Aplikasi

4. Tentang Pabrik

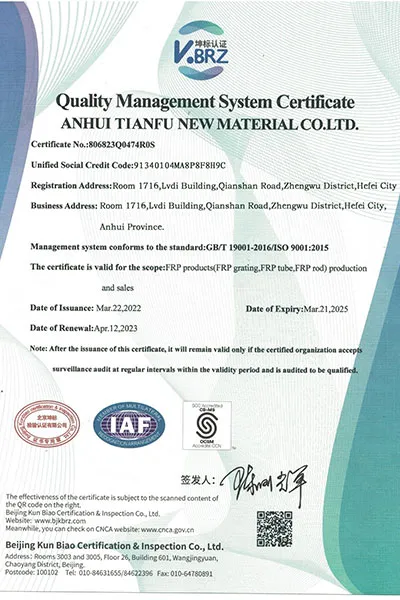

Kami adalah produsen kisi-kisi FRP profesional dengan pengalaman lebih dari 20 tahun. Pabrik kami seluas 26.000㎡ bersertifikasi ISO9001, melayani klien di lebih dari 30 negara dengan kemampuan OEM/ODM. Kami menyediakan solusi yang disesuaikan dan pengiriman cepat ke seluruh dunia.

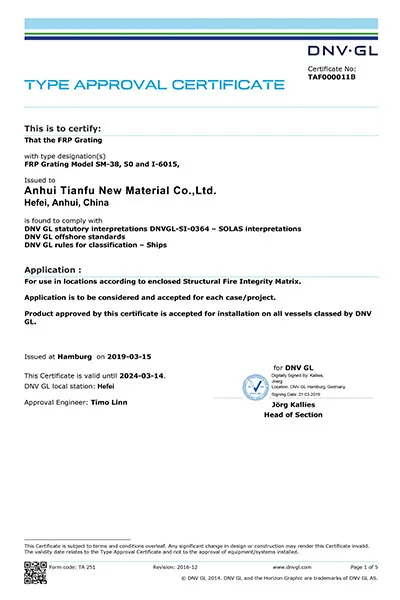

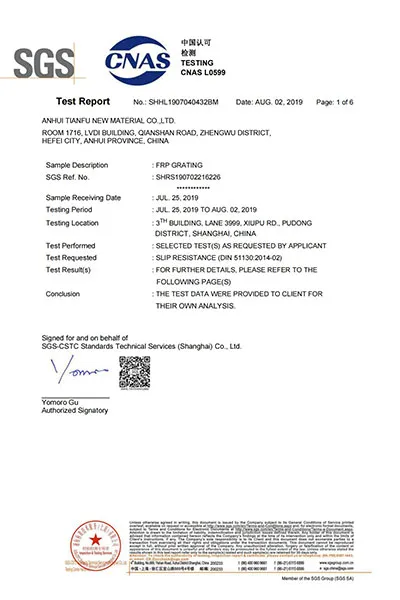

Kisi-kisi FRP kami diproduksi sesuai dengan standar ISO 9001 dan diuji sesuai dengan ASTM E84 (peringkat tahan api Kelas 1), ASTM D638/D790 untuk kinerja mekanis, serta memenuhi standar BS 476 dan EN 13706. Pengujian pihak ketiga tersedia melalui SGS dan TUV berdasarkan permintaan.

Anhui Tianfu New Material Co., Ltd adalah produsen profesional terkemuka yang mengkhususkan diri dalam Kisi-kisi cetakan FRP produksi. Dengan pengalaman lebih dari 20 tahun di industri material komposit, kami berdedikasi untuk memberikan solusi plastik yang diperkuat serat kaca (FRP) berkualitas tinggi untuk berbagai aplikasi industri dan komersial. Pabrik modern kami dilengkapi dengan jalur produksi canggih, meliputi area seluas lebih dari 26.000 meter persegi. Kami menawarkan rangkaian lengkap kisi-kisi FRP cetakan yang memiliki kekuatan unggul, ketahanan kimia, tahan api, dan kinerja anti-selip. Di Tianfu New Material, kami memprioritaskan inovasi, kontrol kualitas yang ketat, dan kepuasan pelanggan. Produk kami bersertifikasi standar internasional dan diekspor ke lebih dari 30 negara di seluruh dunia, melayani industri seperti pabrik kimia, fasilitas pengolahan limbah, platform lepas pantai, dan jalan setapak. Baik Anda membutuhkan ukuran standar atau solusi yang disesuaikan, Tianfu adalah mitra andal Anda untuk kisi-kisi cetakan FRP.

5. Pameran

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

6. Sertifikat

7. Pertanyaan yang Sering Diajukan (FAQ)

Berapakah kapasitas beban kisi-kisi FRP?

- Kapasitas beban bergantung pada ketebalan panel, ukuran jaring, bentang, dan jenis beban. Misalnya, kisi-kisi cetakan setebal 38 mm dengan bentang 1 meter biasanya dapat menahan beban seragam 3–5 kN/m². Aplikasi tugas berat mungkin memerlukan panel yang lebih tebal atau kisi-kisi pultruded.

Bagaimana cara memilih jenis resin yang tepat?

- Resin ortoftalat cocok untuk penggunaan umum;

- Resin isoftalat menawarkan ketahanan korosi yang lebih baik;

- Resin vinil ester Memberikan ketahanan kimia dan panas yang sangat baik. Pilih berdasarkan lingkungan (misalnya, asam, basa, garam, suhu).

Permukaan anti selip apa saja yang tersedia?

- Kisi-kisi FRP dapat diproduksi dengan permukaan berpasir, permukaan cekung, atau puncak meniskus.

Permukaan bertekstur kasar menawarkan daya cengkeram selip tertinggi (hingga R13), sementara permukaan cekung dan meniskus lebih mudah dibersihkan dan cocok untuk area higienis.

Apakah kisi-kisi FRP tahan api?

- Ya, pilihan tahan api tersedia. Produk dapat diproduksi untuk memenuhi persyaratan tertentu. ASTM E84 Kelas 1, EN 13501-1, atau standar tahan api lainnya. Pastikan untuk menentukan ketahanan api saat memesan.

Apakah kisi-kisi FRP dapat dipotong atau dibor di lokasi?

- Ya, dapat dipotong menggunakan gergaji berujung intan atau karbida. Pemotongan sebaiknya dihindari pada batang penahan beban utama jika memungkinkan. Tepi yang terbuka harus ditutup dengan resin untuk menjaga ketahanan terhadap korosi.

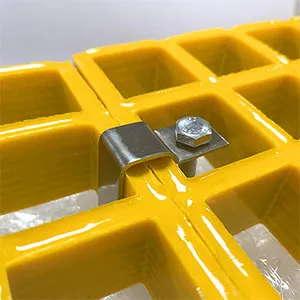

Apa saja metode perbaikan standar?

- Pengencang umum meliputi: Klip M, Klip J, Dan klip L (biasanya baja tahan karat). Di area luar ruangan atau area yang rawan getaran, pengencangan mekanis dengan jangkar direkomendasikan untuk keamanan tambahan.

Apa saja garansi dan perawatan yang biasanya diberikan?

- Sebagian besar pemasok menawarkan garansi 10–15 tahun tergantung pada sistem resin yang digunakan. Kisi-kisi FRP membutuhkan perawatan minimal—hanya pembersihan berkala dan pengecekan klip yang longgar. Tidak diperlukan pengecatan atau perawatan anti karat.

8. Produk Lainnya

9. Tur Pabrik VR