Introduzione alle prestazioni del prodotto

Le griglie metalliche sono un materiale durevole e ad alta resistenza, ampiamente utilizzato in applicazioni industriali, commerciali e architettoniche. Realizzate con materiali come acciaio al carbonio, acciaio zincato, alluminio e acciaio inossidabile, le griglie metalliche sono progettate per offrire un'eccellente capacità portante, consentendo al contempo ventilazione, illuminazione e drenaggio. La loro struttura a griglia aperta le rende una soluzione affidabile per pavimentazioni, passerelle, gradini, soppalchi, piattaforme, passerelle e coperture di trincee in ambienti che richiedono resistenza, sicurezza e lunga durata.

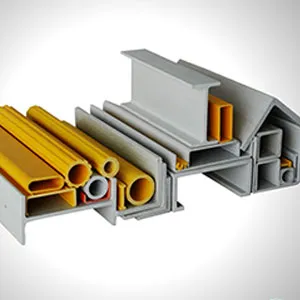

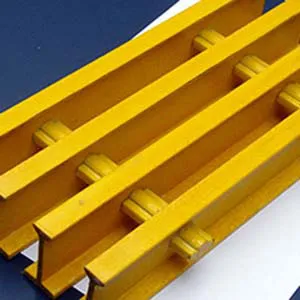

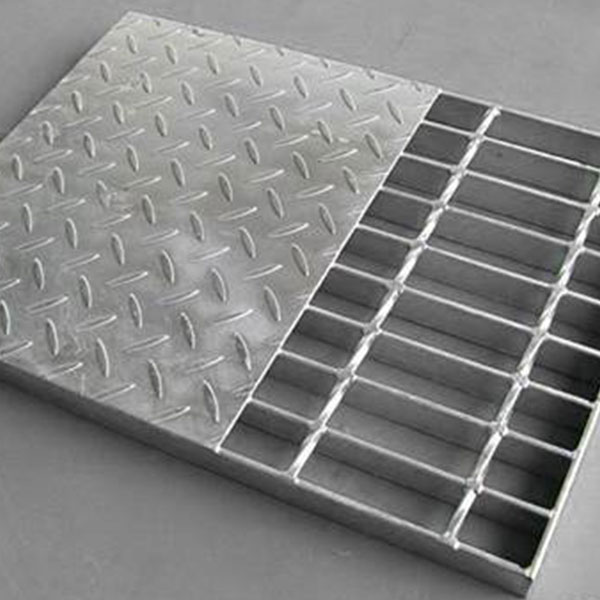

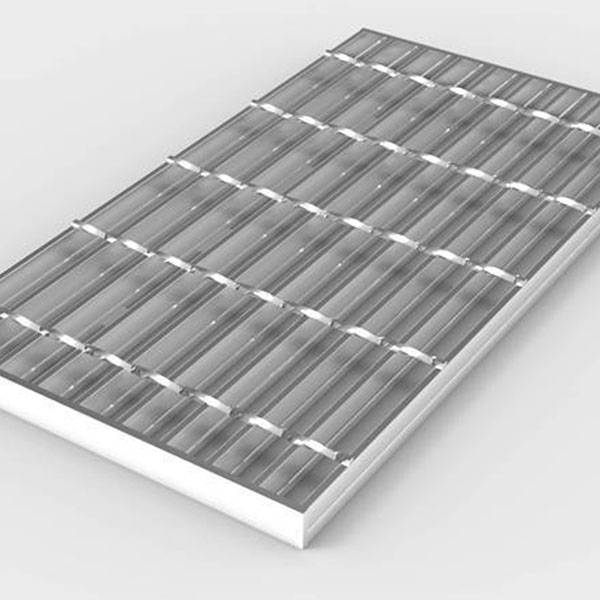

Sono disponibili diversi tipi di grate metalliche, tra cui grigliato in barre di acciaio saldate, griglia pressata, E grigliato in metallo espanso. Il grigliato saldato, il tipo più comune, è realizzato saldando barre perpendicolari per creare una struttura rigida e resistente. Il grigliato pressato offre un aspetto pulito con barre bloccate in posizione ad alta pressione, ideale per uso architettonico. Il grigliato in lamiera stirata è prodotto tagliando e stirando lamiere, formando un motivo a maglia perfetto per superfici leggere e antiscivolo.

La griglia metallica è apprezzata per la sua superficie antiscivolo, resistenza alla deformazione, E adattabilità alle specifiche personalizzate. Può essere realizzato con bordi seghettati per una maggiore resistenza allo scivolamento o rivestito con trattamenti anticorrosione per ambienti esterni o corrosivi. Le opzioni in acciaio zincato e inossidabile offrono un'eccellente resistenza alla corrosione, rendendole ideali per impianti navali, chimici e di lavorazione alimentare.

Dai pavimenti industriali pesanti ai moderni sistemi di drenaggio urbano, le griglie metalliche sono un materiale affidabile che soddisfa rigorosi standard di sicurezza e offre valore a lungo termine. La facilità di installazione, la manutenzione minima e la riciclabilità contribuiscono inoltre alla sua popolarità in una vasta gamma di settori.

Specifiche e parametri tecnici delle griglie metalliche

| Parametro | Opzioni di specificazione |

|---|---|

| Materiale | Acciaio al carbonio, acciaio zincato, acciaio inossidabile, alluminio |

| Tipo | Grigliati saldati, grigliati pressati, grigliati in lamiera stirata |

| Dimensioni della barra (larghezza × spessore) | 20×3 mm, 25×3 mm, 30×3 mm, 40×5 mm, disponibili su misura |

| Passo della barra portante | 20 millimetri, 25 millimetri, 30 millimetri, 40 millimetri, 60 millimetri |

| Passo della barra trasversale | 50 mm, 100 mm o personalizzato |

| Finitura superficiale | Finitura grezza, zincata a caldo, verniciata a polvere, verniciata |

| Tipo di superficie | Liscio o dentellato (antiscivolo) |

| Capacità di carico | Da leggero a pesante (in base alla campata e alle dimensioni delle barre) |

| Intervallo di span | Campate comuni: 600 mm – 1500 mm (personalizzabili in base al carico) |

| Area aperta | Tipicamente 70% – 80% a seconda del tipo e della spaziatura |

| Dimensioni standard del pannello | 1000 mm × 6000 mm, 1000 mm × 3000 mm (disponibili dimensioni personalizzate) |

| Standard di conformità | ANSI/NAAMM MBG 531, BS 4592, AS 1657 (varia in base alla regione) |

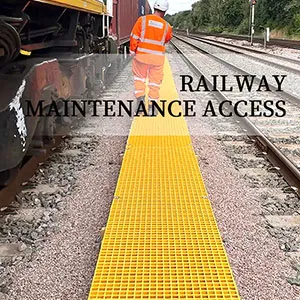

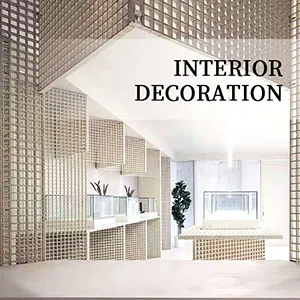

| Applicazioni | Passerelle, gradini, piattaforme, coperture di trincee, rampe, recinzioni |

Perché sceglierci

Competenza nella produzione di grigliati in FRP

Con oltre 20 anni di esperienza, il nostro stabilimento è specializzato esclusivamente nella progettazione, sviluppo e produzione di grigliati in FRP (plastica rinforzata con fibra di vetro) ad alte prestazioni. La nostra profonda conoscenza del settore garantisce che ogni prodotto soddisfi i più rigorosi standard industriali.

Tecnologia e attrezzature avanzate

Utilizziamo macchinari di produzione all'avanguardia e tecnologie di stampaggio di precisione per realizzare grigliati con resistenza, resistenza alla corrosione e precisione dimensionale superiori. Il nostro impegno per l'innovazione significa che il vostro progetto beneficia dei più recenti progressi nella tecnologia FRP.

Soluzioni personalizzate

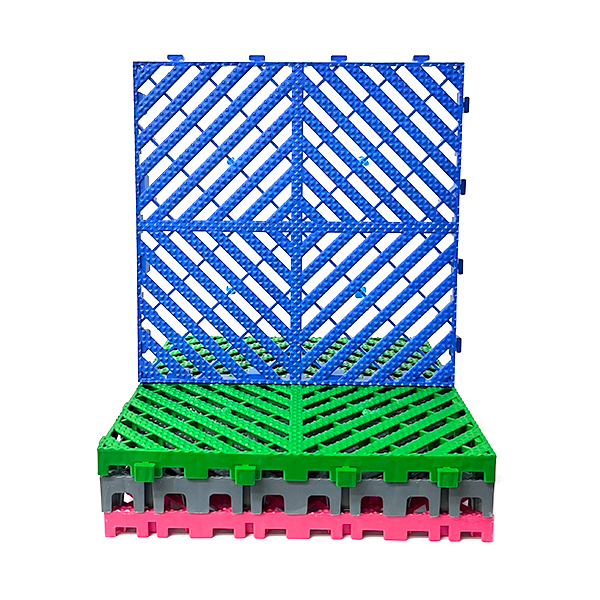

Dalle dimensioni dei pannelli e dai tipi di resina alle finiture e ai colori delle superfici, offriamo una personalizzazione completa per soddisfare le vostre specifiche esigenze applicative, che si tratti di pavimenti industriali, gradini di scale, coperture di trincee o piattaforme marine.

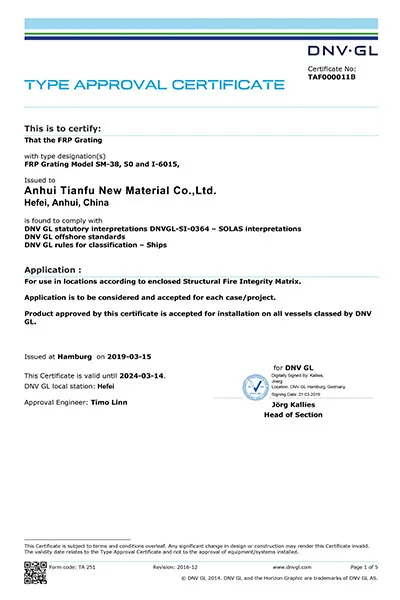

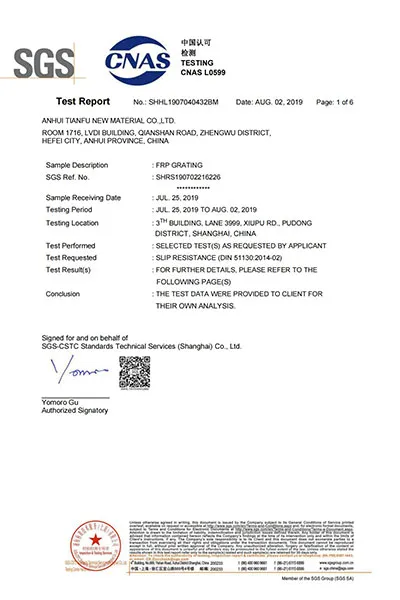

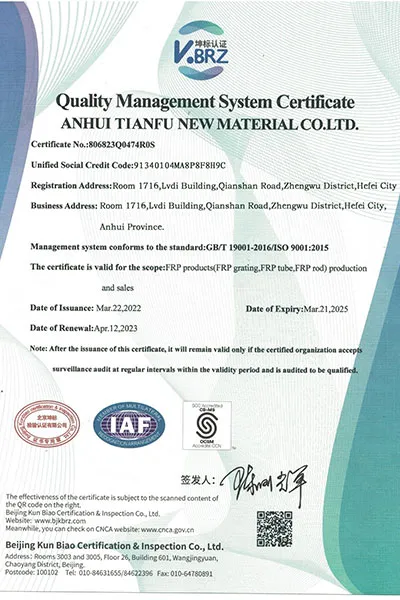

Controllo di qualità rigoroso

Ogni prodotto viene sottoposto a un rigoroso processo di controllo qualità, che include prove di carico, controlli di ignifugazione e analisi di resistenza alla corrosione. Il nostro sistema di gestione della qualità certificato ISO garantisce un'eccellenza costante in ogni lotto.

Prezzi competitivi

Offriamo prezzi di fabbrica diretti senza compromettere la qualità. Grazie a processi produttivi ottimizzati e capacità di produzione in serie, aiutiamo i nostri clienti a ottenere risparmi sui costi su larga scala.

Consegna affidabile e portata globale

Disponiamo di un ampio stock di prodotti standard e gestiamo un sistema logistico efficiente, garantendo tempi di consegna rapidi a livello locale e internazionale. Abbiamo servito con successo clienti in oltre 15 paesi.

Prodotti più venduti

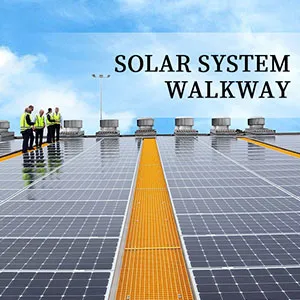

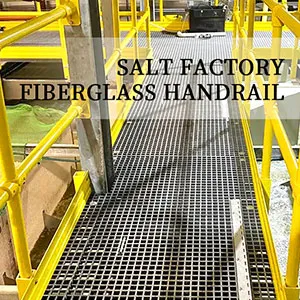

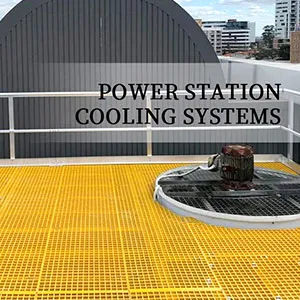

Scenari applicativi

Informazioni sulla fabbrica

Siamo un produttore professionale di grigliati in FRP con oltre 20 anni di esperienza. Il nostro stabilimento di 26.000 m² è certificato ISO9001 e serve clienti in oltre 30 paesi con capacità OEM/ODM. Offriamo soluzioni personalizzate e consegne rapide in tutto il mondo.

I nostri grigliati in FRP sono realizzati in conformità con gli standard ISO 9001 e testati secondo ASTM E84 (classe di resistenza al fuoco 1), ASTM D638/D790 per le prestazioni meccaniche e sono conformi agli standard BS 476 ed EN 13706. Su richiesta, sono disponibili test di terze parti tramite SGS e TUV.

Esposizione

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

Certificato

Altri prodotti

Tour della fabbrica VR

Griglia metallica

Serie:

prodotti >applicazione

Passerelle, gradini, piattaforme, coperture di trincee, rampe, recinzioni

Tipo :

Griglia metallica

Materiale :

Acciaio al carbonio, acciaio zincato, acciaio inossidabile, alluminio

Tipo :

Grigliati saldati, grigliati pressati, grigliati in lamiera stirata

Dimensioni della barra (larghezza × spessore):

20×3 mm, 25×3 mm, 30×3 mm, 40×5 mm, disponibili su misura

Passo della barra portante:

20 millimetri, 25 millimetri, 30 millimetri, 40 millimetri, 60 millimetri

FAQ

Q :

Quali tipi di griglie metalliche sono disponibili?

UN :

Le tipologie più comuni sono il grigliato a barre saldate, il grigliato pressato e il grigliato in lamiera stirata. Ogni tipologia offre diversi vantaggi strutturali ed estetici a seconda dell'applicazione.

Q :

Con quali materiali si possono realizzare le griglie metalliche?

UN :

Le griglie metalliche sono solitamente realizzate in acciaio al carbonio, acciaio zincato, acciaio inossidabile o alluminio. La scelta del materiale dipende da fattori come i requisiti di carico, la resistenza alla corrosione e le condizioni ambientali.

Q :

Quali sono le opzioni di superficie disponibili?

UN :

Le griglie metalliche sono disponibili con una superficie liscia o dentellata (antiscivolo) per una maggiore sicurezza in ambienti umidi o oleosi.

Q :

La griglia può essere personalizzata?

UN :

Sì, le griglie metalliche possono essere personalizzate in termini di dimensioni delle barre, spaziatura, dimensioni dei pannelli, finitura superficiale e materiale. Molti produttori offrono anche forme personalizzate e servizi di fabbricazione.

Q :

Le griglie metalliche sono adatte all'uso esterno?

UN :

Sì. Le griglie in acciaio zincato o inossidabile sono altamente resistenti alla ruggine e alla corrosione, il che le rende ideali per ambienti esterni, marini o industriali.

Q :

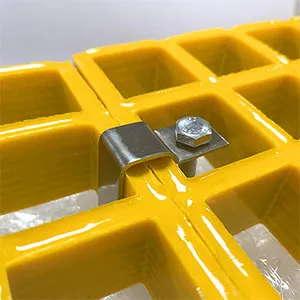

Come si installa la griglia metallica?

UN :

Le griglie metalliche possono essere installate mediante saldatura, serraggio o bullonatura, a seconda della struttura e dell'applicazione. Spesso vengono utilizzate clip per facilitarne la rimozione e la manutenzione.

Q :

Quali sono le applicazioni tipiche delle griglie metalliche?

UN :

È ampiamente utilizzato in pavimentazioni industriali, passerelle, gradini di scale, soppalchi, passerelle, coperture di trincee e piattaforme di ventilazione in settori quali petrolio e gas, centrali elettriche, edilizia e estrazione mineraria.

Altri prodotti correlati