Introdução ao desempenho do produto

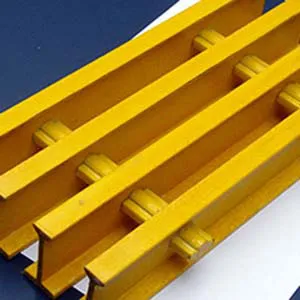

A grade de fibra de vidro com superfície sólida e antiderrapante é um tipo especializado de grade de PRFV (plástico reforçado com fibra de vidro) que combina os benefícios estruturais da fibra de vidro com uma superfície superior completamente selada e impermeável, além de uma camada antiderrapante. Ao contrário das grades de fibra de vidro tradicionais com malha aberta, o design com superfície sólida impede a passagem de líquidos, detritos ou pequenas ferramentas, tornando-a ideal para ambientes que exigem contenção máxima e uma superfície limpa para circulação.

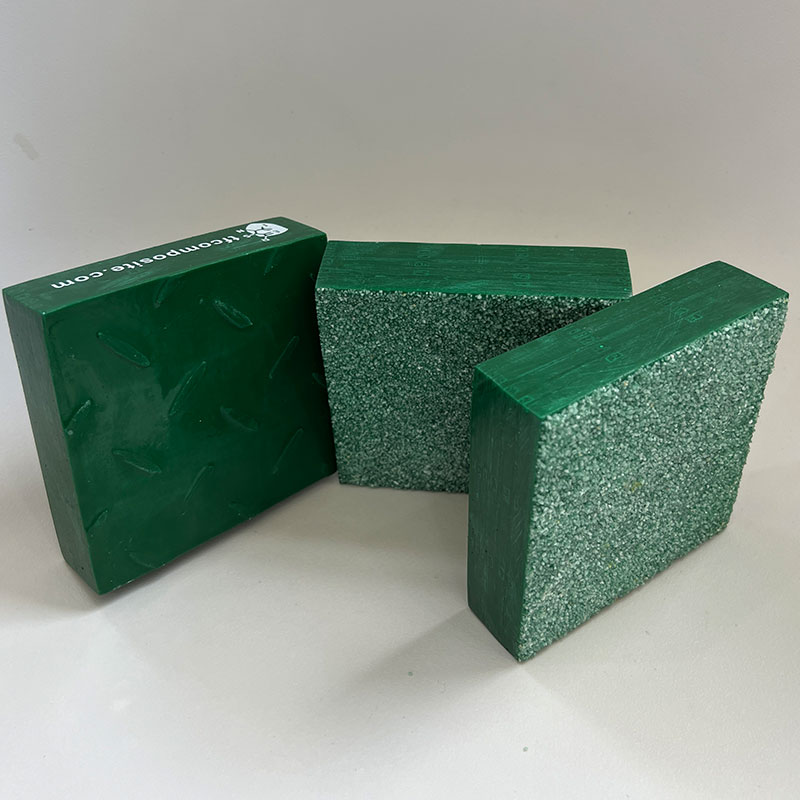

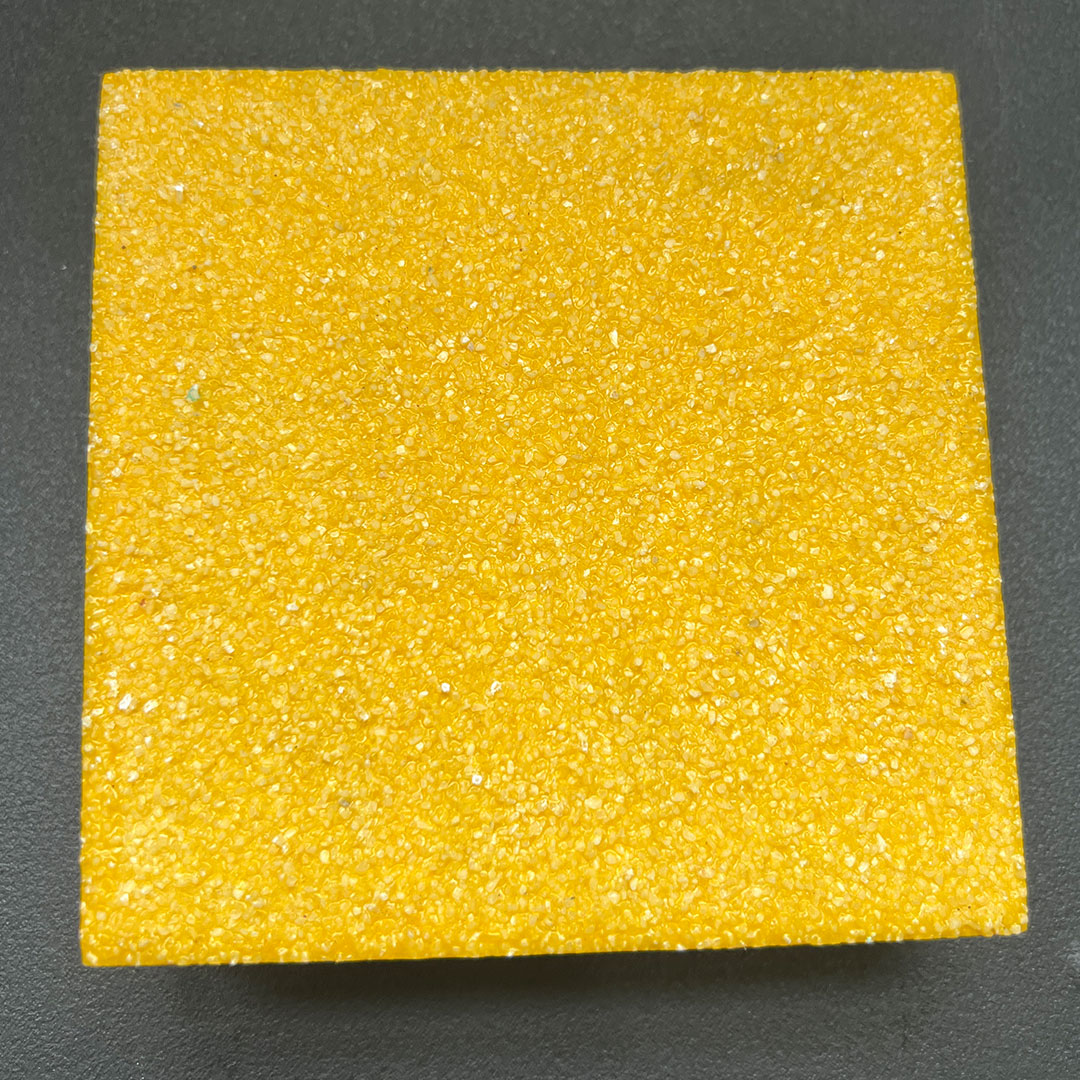

O superfície áspera A superfície sólida é geralmente revestida com uma camada de grânulos duráveis de quartzo ou óxido de alumínio. Essa camada proporciona resistência ao deslizamento excepcional, mesmo em condições oleosas, molhadas ou outras condições perigosas. O resultado é uma superfície de caminhada que atende ou supera as diretrizes da OSHA e da ADA para prevenção de escorregões.

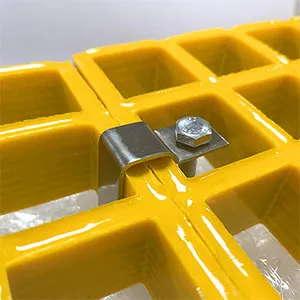

Características principais:

- Superfície seladaA tampa sólida impede a contaminação por cima ou por baixo, tornando-a adequada para aplicações onde a higiene ou o controle de detritos são importantes.

- Anti-derrapanteO acabamento texturizado oferece excelente tração, reduzindo o risco de escorregões e quedas em áreas industriais ou de grande circulação.

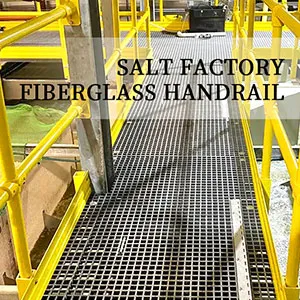

- Resistente a corrosãoFabricada com materiais não metálicos, a grade resiste à corrosão causada por produtos químicos, água salgada e solventes industriais.

- Não CondutivoSua estrutura de fibra de vidro não conduz eletricidade, tornando-a ideal para uso próximo a equipamentos elétricos.

Aplicações comuns:

- Fábricas de processamento de alimentos e bebidas (zonas sem contato com alimentos)

- áreas de fabricação de produtos químicos

- Salas de carregamento de baterias

- Passarelas acima de máquinas sensíveis

- Valetas e passarelas para serviços públicos

- Plataformas marítimas e offshore

Especificações e parâmetros técnicos de grades de PRFV (Plástico Reforçado com Fibra de Vidro)

1. Especificações Gerais

| Item | Descrição |

|---|---|

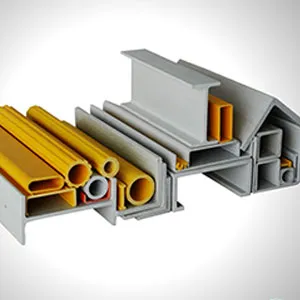

| Tipo de produto | Grelha moldada em PRFV / Grelha pultrudada em PRFV |

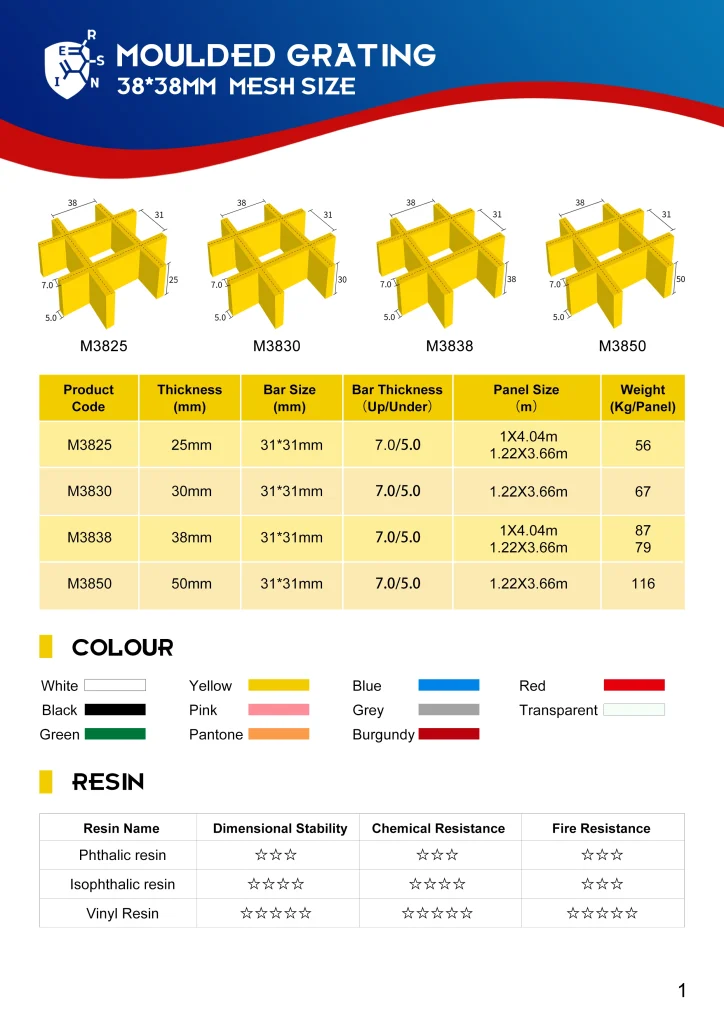

| Tamanho da malha | 38×38 mm (1,5″x1,5″) / 40×40 mm / Personalizado |

| Espessura (Altura) | 25 mm / 30 mm / 38 mm / 50 mm |

| Tamanho do painel | 1220×3660 mm / 1000×4000 mm / Personalizado |

| Área aberta | 60% – 70% (dependendo do tamanho da malha) |

| Opções de superfície | Superfície áspera / côncava / lisa / coberta |

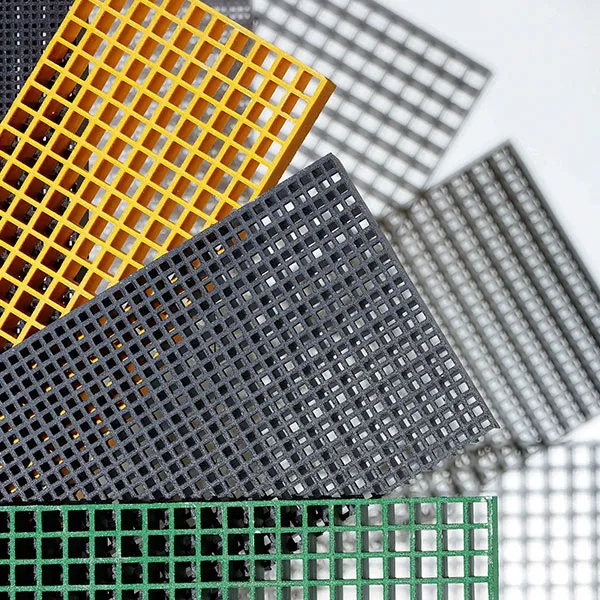

| Cor | Cinza, Amarelo, Verde, Vermelho, Personalizado |

2. Propriedades Mecânicas (Valores Típicos)

| Propriedade | Valor | Padrão de teste |

|---|---|---|

| Resistência à tracção | ≥ 120 MPa (17.400 psi) | ASTM D638 |

| Resistência à flexão | ≥ 200 MPa (29.000 psi) | ASTM D790 |

| Módulo de Flexão | ≥ 7.800 MPa (1,13×10⁶ psi) | ASTM D790 |

| Resistência à compressão | ≥ 200 MPa (29.000 psi) | ASTM D695 |

| Resistência ao impacto (Izod) | ≥ 85 J/m | ASTM D256 |

| Dureza Barcol | ≥ 40 | ASTM D2583 |

3. Propriedades Físicas e Químicas

| Propriedade | Valor | Padrão de teste |

|---|---|---|

| Densidade | ~1,8–2,0 g/cm³ | ASTM D792 |

| Absorção de água | < 0,5% | ASTM D570 |

| Retardante de chamas | ≤ 25 (Classe 1) | ASTM E84 |

| Resistência UV | Disponível com inibidor de UV | – |

| Condutividade elétrica | Não Condutivo | – |

| Condutividade térmica | ~0,25 W/m·K | ASTM C177 |

| Faixa de temperatura operacional | -50°C a +120°C (varia conforme a resina) | – |

4. Sistemas de resina disponíveis

| Tipo de resina | Características | Áreas de aplicação |

|---|---|---|

| Ortoftálico | Uso geral, custo-benefício | Indústria em geral, pisos |

| Isoftálico | Melhor resistência química | Águas residuais, processamento de alimentos |

| Éster vinílico | Excelente resistência química e à corrosão | Fábricas de produtos químicos, plataformas marítimas, mineração |

| fenólico | Resistência ao fogo e à fumaça | Petróleo e gás, transporte, marítimo |

5. Tabela de Carga (Exemplo para Grelha de 38mm de Espessura)

| Vão (mm) | Carga (kN/m²) | Deflexão (mm) |

|---|---|---|

| 600 | 5.0 | 4.5 |

| 800 | 3.5 | 5.9 |

| 1000 | 2.0 | 7.6 |

Por que nos escolher?

Especialização na fabricação de grades de PRFV (Plástico Reforçado com Fibra de Vidro)

Com mais de 20 anos de experiência, nossa fábrica se especializa exclusivamente no projeto, desenvolvimento e produção de grades de PRFV (Plástico Reforçado com Fibra de Vidro) de alto desempenho. Nosso profundo conhecimento do setor garante que cada produto atenda aos mais exigentes padrões industriais.

Tecnologia e equipamentos avançados

Utilizamos equipamentos de fabricação de última geração e tecnologia de moldagem de precisão para produzir grades com resistência superior, resistência à corrosão e precisão dimensional. Nosso compromisso com a inovação significa que seu projeto se beneficia dos mais recentes avanços na tecnologia de PRFV (Plástico Reforçado com Fibra de Vidro).

Soluções personalizadas

Desde o tamanho dos painéis e tipos de resina até os acabamentos de superfície e cores, oferecemos personalização completa para atender às suas necessidades específicas de aplicação — sejam pisos industriais, degraus de escada, tampas de valas ou plataformas marítimas.

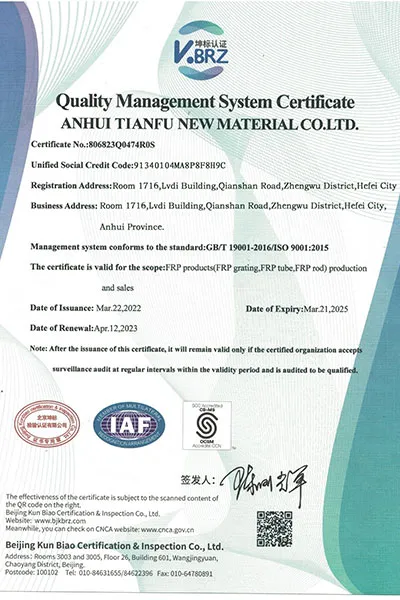

Controle de qualidade rigoroso

Cada produto passa por um rigoroso processo de inspeção de qualidade, incluindo testes de carga, verificação de resistência à chama e análise de resistência à corrosão. Nosso sistema de gestão da qualidade com certificação ISO garante excelência consistente em cada lote.

Preços competitivos

Oferecemos preços direto da fábrica sem comprometer a qualidade. Com processos de produção otimizados e capacidade de fabricação em larga escala, ajudamos nossos clientes a obter economia de custos em grande escala.

Entrega confiável e alcance global

Mantemos um amplo estoque de produtos padrão e operamos um sistema logístico otimizado, garantindo prazos de entrega rápidos em âmbito nacional e internacional. Atendemos com sucesso clientes em mais de 15 países.

Produtos mais vendidos

| Tamanhos padrão de painéis | 1220 mm × 3660 mm (4 pés × 12 pés) 1220 mm × 4000 mm (4 pés × 13,1 pés) 915 mm × 3050 mm (3 pés × 10 pés) 1000 mm × 3000 mm (personalizável) (Outros tamanhos podem ser personalizados de acordo com as necessidades do projeto.) |

| Opções de espessura | 25 mm (1 polegada) 30 mm (1,2 polegadas) 38 mm (1,5 polegadas) — o mais comum 50 mm (2 polegadas) |

| Tamanho da malha (tamanho da abertura) | 38 mm × 38 mm (1,5 polegadas × 1,5 polegadas) — Padrão 40 mm × 40 mm 19 mm × 19 mm (mini-malha para impedir a passagem de pequenos objetos) |

| Largura e espaçamento da barra de carga (para grades pultrudadas) | Largura da barra de carga: normalmente 25 mm, 38 mm, 50 mm Espaçamento das barras de carga: 25 mm, 40 mm, 50 mm de centro a centro |

| Opções de superfície | Superfície áspera (antiderrapante) Superfície lisa Superfície coberta (tampo sólido) |

| Cores disponíveis | Amarelo (mais comum) Verde Cinza Vermelho Cores personalizadas sob encomenda |

| Tipos comuns de resina | Poliéster Isoftálico (resistência à corrosão padrão) Éster vinílico (alta resistência química) Fenólico (aplicações resistentes ao fogo) |

Sobre a fábrica

Anhui Tianfu New Material Co., Ltd é um fabricante profissional líder especializado em Grelha moldada em PRFV Com mais de 20 anos de experiência na indústria de materiais compósitos, dedicamo-nos a fornecer soluções de alta qualidade em plástico reforçado com fibra de vidro (PRFV) para uma ampla gama de aplicações industriais e comerciais. Nossa moderna fábrica está equipada com linhas de produção avançadas, abrangendo uma área de mais de 26.000 metros quadrados. Oferecemos uma linha completa de grades moldadas em PRFV com resistência superior, resistência química, retardamento de chamas e propriedades antiderrapantes. Na Tianfu New Material, priorizamos a inovação, o rigoroso controle de qualidade e a satisfação do cliente. Nossos produtos são certificados segundo normas internacionais e exportados para mais de 30 países em todo o mundo, atendendo a setores como plantas químicas, estações de tratamento de esgoto, plataformas offshore e passarelas. Seja qual for a sua necessidade, tamanhos padrão ou soluções personalizadas, a Tianfu é sua parceira confiável em grades moldadas em PRFV.

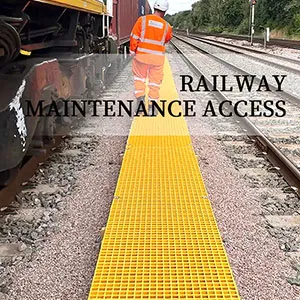

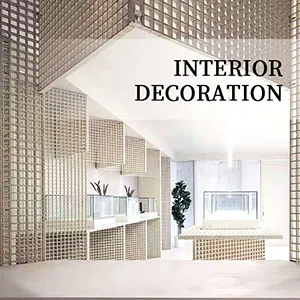

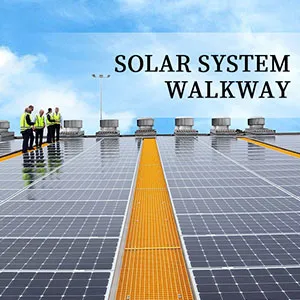

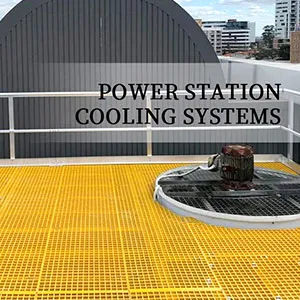

Cenários de Aplicação

Sobre a fábrica

Somos um fabricante profissional de grades de PRFV (Plástico Reforçado com Fibra de Vidro) com mais de 20 anos de experiência. Nossa fábrica de 26.000 m² possui certificação ISO 9001 e atende clientes em mais de 30 países, com capacidade de fabricação OEM/ODM. Oferecemos soluções personalizadas e entrega rápida em todo o mundo.

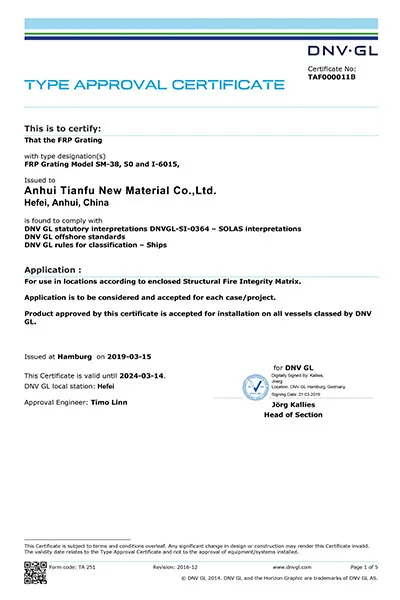

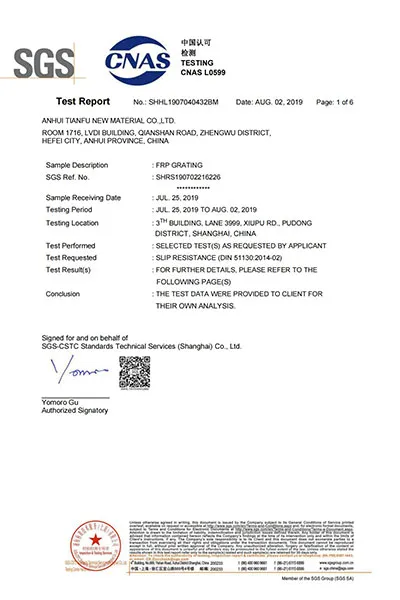

Nossas grades de PRFV são fabricadas de acordo com as normas ISO 9001 e testadas segundo as normas ASTM E84 (classificação de resistência ao fogo Classe 1), ASTM D638/D790 para desempenho mecânico, e estão em conformidade com as normas BS 476 e EN 13706. Testes de terceiros estão disponíveis através da SGS e da TÜV mediante solicitação.

Exibição

JEC WORLD 2023

MUNDO JEC 2024

CAMX 2025

XANGAI 2025

Certificado

Grelha moldada em PRFV TDS

Outros produtos

Tour virtual pela fábrica

Grelha de fibra de vidro com superfície sólida e granulada.

Series :

Grade Moldada em Fibra de Vidro >aplicativo

Pisos industriais, plataformas marítimas e offshore, estações de tratamento de águas residuais, indústria de alimentos e bebidas, infraestrutura de transporte, canteiros de obras, salas de baterias e subestações elétricas, espaços públicos e comerciais, parques aquáticos e piscinas, sistemas de climatização (HVAC) e coberturas.

Tamanho da malha:

38x38 mm (1,5

Espessura (Altura):

25 mm / 30 mm / 38 mm / 50 mm

Dimensões do painel:

1220x3660 mm / 1000x4000 mm / Personalizado

Área aberta:

60% – 70% (dependendo do tamanho da malha)

Opções de superfície:

Superfície áspera / côncava / lisa / coberta

Cor :

Cinza, Amarelo, Verde, Vermelho, Personalizado

Perguntas frequentes

P:

O que é uma grade de fibra de vidro com superfície áspera e topo sólido?

A :

Trata-se de uma grade reforçada com fibra de vidro, com uma superfície superior plana e selada, revestida por uma camada de grãos aderidos para maior resistência ao deslizamento. Ao contrário das grades de malha aberta, ela impede a passagem de objetos e fluidos.

P:

Onde é normalmente utilizada a grelha sólida superior?

A :

É ideal para corredores industriais, fábricas de produtos químicos, salas de baterias, processamento de alimentos (zonas sem contato), plataformas marítimas e áreas onde a contenção de detritos ou líquidos é importante.

P:

A superfície texturizada é segura em ambientes úmidos ou oleosos?

A :

Sim. A camada de areia proporciona excelente tração e foi projetada para reduzir escorregões em condições de piso molhado, oleoso ou de alto tráfego, atendendo inclusive aos padrões antiderrapantes da OSHA e da ADA.

P:

A superfície sólida pode ser lavada com jato de água ou limpa facilmente?

A :

Sim. A superfície selada pode ser limpa com água, detergente neutro ou lavagem com jato de água de alta pressão. No entanto, esponjas abrasivas podem reduzir a vida útil da camada de areia.

P:

A grelha superior sólida está disponível em diferentes espessuras e tamanhos?

A :

Sim. Está disponível em vários tamanhos e espessuras de painel, geralmente de 3/4" a 2", dependendo dos requisitos de carga. Dimensões personalizadas e opções de corte sob medida também estão disponíveis.

P:

Oferece a mesma resistência que uma grade de fibra de vidro de malha aberta?

A :

Os painéis superiores maciços são estruturalmente reforçados para suportar cargas industriais. Eles podem até proporcionar uma melhor distribuição de peso devido à superfície contínua.

P:

Quais os tipos de resina disponíveis para grelhas com superfície sólida?

A :

Está disponível em tipos de resina como poliéster isoftálico, vinil éster e fenólico, dependendo da resistência química, retardância ao fogo e durabilidade ambiental necessárias.

Outros produtos relacionados