Introdução ao desempenho do produto

FRP (Fiberglass Reinforced Plastic) water storage tanks are high-performance, corrosion-resistant vessels engineered for safe and long-term water containment in a wide variety of applications. Manufactured by combining a thermosetting resin matrix with continuous fiberglass reinforcement, these tanks offer a robust, lightweight, and chemically stable solution to traditional metal or concrete tanks.

Material Advantages

The defining feature of FRP water tanks is their composite structure. The fiberglass reinforcement provides excellent mechanical strength, while the resin matrix (typically isophthalic polyester, vinyl ester, or epoxy resin) ensures chemical and moisture resistance. This combination leads to several distinct advantages:

- Resistência à corrosão: Unlike steel tanks, FRP tanks do not rust or corrode when exposed to water, chemicals, or saline environments. This makes them ideal for both potable and non-potable water storage, including brackish or demineralized water.

- Lightweight Structure: FRP tanks are significantly lighter than steel or concrete tanks of similar capacity, which makes transportation, lifting, and installation easier and more cost-effective.

- Baixa manutenção: The non-reactive surface and UV-stabilized outer layer reduce algae growth and degradation from sunlight. FRP tanks require little to no maintenance over their lifespan.

- Alta relação resistência/peso: Despite being lightweight, FRP tanks are structurally strong and capable of withstanding internal hydraulic pressures and environmental stress.

Design & Configuration

FRP water tanks are available in various designs and configurations, depending on storage capacity, application, and site conditions:

- Vertical Cylindrical Tanks – For standard ground-level installations

- Horizontal Tanks – Ideal for transport and mobile storage

- Rectangular or Square Tanks – Custom-shaped for restricted spaces

- Modular Panel Tanks (SMC type) – Assembled on-site for large-capacity requirements

Tank capacities typically range from a few hundred liters to over 500,000 liters (500 m³), and can be fabricated with flat, domed, or conical tops and bottoms.

FRP Water Tank Specifications & Technical Parameters

1. Material Composition

- Resins Used:

- Resina Poliéster Isoftálica – for general water storage

- Resina Vinil Ester – for enhanced chemical and thermal resistance

- Bisphenol-A Epoxy Resin – for special applications requiring high strength and durability

- Reinforcement:

- High-strength continuous glass fiber rovings, chopped strand mat (CSM), or woven roving

- Optional surface veil (e.g., C-glass veil) for additional corrosion resistance

2. Mechanical Properties

| Propriedade | Typical Value |

|---|---|

| Resistência à tracção | ≥ 100–200 MPa |

| Resistência à flexão | ≥ 250–300 MPa |

| Resistência à compressão | ≥ 200–250 MPa |

| Elastic Modulus (Flexural) | 20–30 GPa |

| Impact Resistance (Izod) | ≥ 90 J/m |

| Hydrostatic Pressure Resistance | Designed for pressure up to 10 bar or more |

3. Physical Properties

| Propriedade | Typical Value |

|---|---|

| Densidade | 1.5 – 2.0 g/cm³ |

| Water Absorption (24h) | ≤ 0.2% |

| Thermal Conductivity | ~0.25 – 0.35 W/m·K |

| Operating Temperature Range | -40°C to +120°C (up to 180°C with special resins) |

| Resistência UV | Excellent (with UV-stabilized gelcoat) |

4. Chemical Resistance

- Suitable for storage of:

- Potable water (certified)

- Saltwater or brackish water

- Light acidic or alkaline fluids (customized resin formulation)

- Not recommended for strong oxidizers unless specially designed

5. Electrical Properties

| Propriedade | Typical Value |

|---|---|

| Dielectric Strength | ≥ 20 kV/mm |

| Surface Resistivity | > 10¹² ohm |

| Non-conductive and EMI-proof | Sim |

6. Tank Dimensions & Design Options

| Configuration | Standard Range |

|---|---|

| Volume Capacity | 500 liters to 500,000+ liters |

| Diameter | 0.5 m to 6 m (or customized) |

| Altura | Custom based on volume and location |

| Grossura | 3 mm to 50 mm (depending on pressure) |

| Tank Types | Vertical / Horizontal / Modular Panel |

| Head Types | Flat / Dished / Conical / Domed |

| Orientation | Above-ground / Underground |

7. Surface Finish & Color

- Inner Lining: Food-grade resin or smooth anti-fouling surface

- Outer Surface: UV-stabilized pigmented resin (common colors: blue, green, gray)

- Optional: Gelcoat with anti-UV, anti-static, or fire-retardant properties

8. Standards & Certifications

- ASTM D3299 – Standard for filament-wound FRP tanks

- ASTM D4097 – Standard for contact-molded FRP tanks

- NSF/ANSI 61 – For potable water storage

- ISO 9001 – Manufacturing quality system compliance

- BS EN 13280 – Water tanks for building use

- AWWA D120 / D121 – Water storage tank standards (if applicable)

Why Choose Us

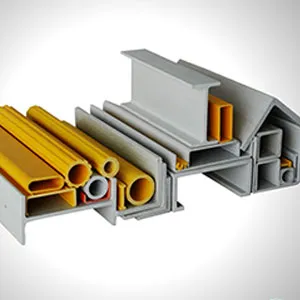

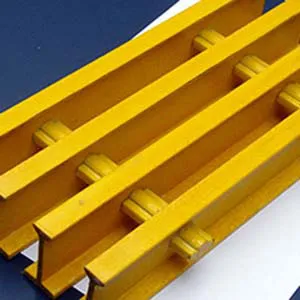

Expertise in FRP Grating Manufacturing

With over 20 years of experience, our factory specializes exclusively in the design, development, and production of high-performance FRP (Fiberglass Reinforced Plastic) gratings. Our deep industry knowledge ensures that every product meets the most demanding industrial standards.

Advanced Technology and Equipment

We utilize state-of-the-art manufacturing equipment and precision molding technology to produce gratings with superior strength, corrosion resistance, and dimensional accuracy. Our commitment to innovation means your project benefits from the latest advancements in FRP technology.

Customized Solutions

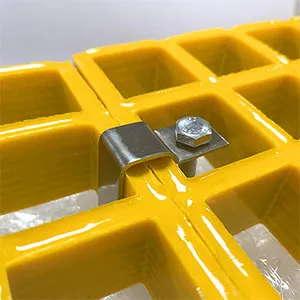

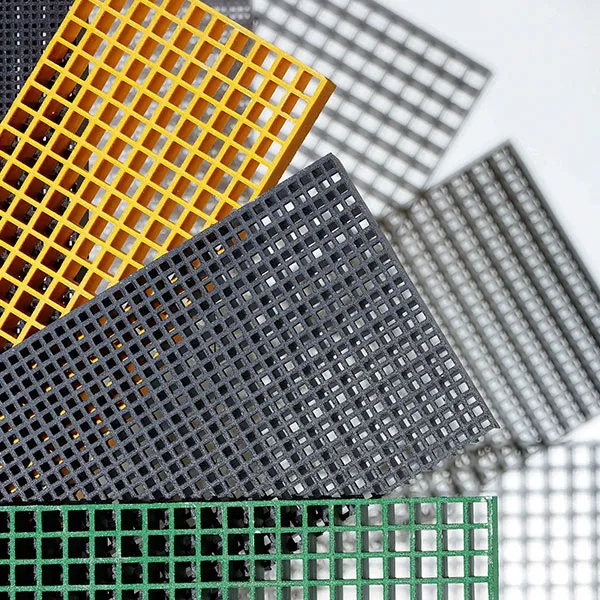

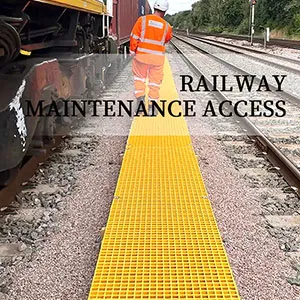

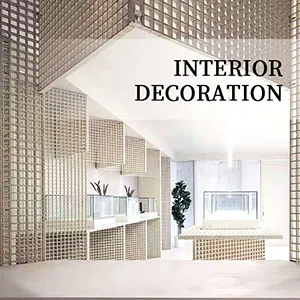

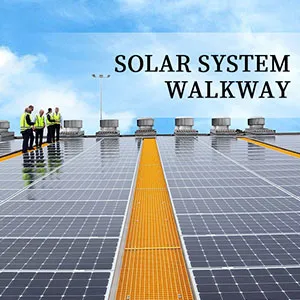

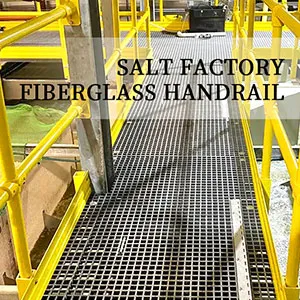

From panel sizes and resin types to surface finishes and colors, we offer complete customization to meet your unique application needs—be it industrial flooring, stair treads, trench covers, or marine platforms.

Stringent Quality Control

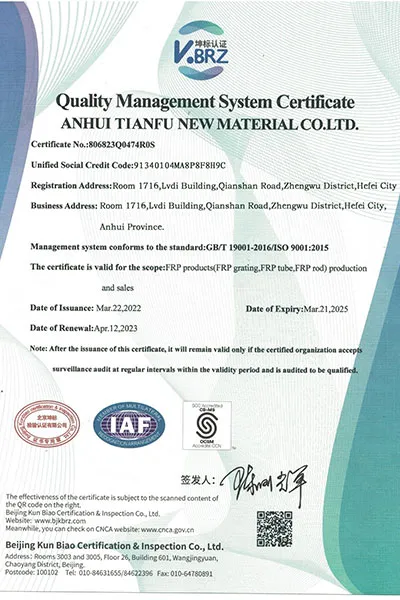

Every product undergoes a rigorous quality inspection process, including load testing, flame retardance checks, and corrosion resistance analysis. Our ISO-certified quality management system ensures consistent excellence in every batch.

Competitive Pricing

We offer factory-direct pricing without compromising on quality. With optimized production processes and bulk manufacturing capabilities, we help our customers achieve cost savings at scale.

Reliable Delivery and Global Reach

We maintain a large stock of standard products and operate a streamlined logistics system, ensuring fast delivery times locally and internationally. We’ve successfully served clients in over 15 countries.

Hot-Selling Products

| Standard Panel Sizes | 1220 mm × 3660 mm (4 ft × 12 ft) 1220 mm × 4000 mm (4 ft × 13.1 ft) 915 mm × 3050 mm (3 ft × 10 ft) 1000 mm × 3000 mm (customizable) (Other sizes can be customized according to project needs) |

| Thickness Options | 25 mm (1 polegada) 30 mm (1.2 inch) 38 mm (1.5 inch) — most common 50 mm (2 inch) |

| Mesh Size (Opening Size) | 38 mm × 38 mm (1.5 inch × 1.5 inch) — Standard 40 mm × 40 mm 19 mm × 19 mm (mini-mesh for small object passage prevention) |

| Load Bar Width and Spacing (for Pultruded Grating) | Load bar width: typically 25 mm, 38 mm, 50 mm Load bar spacing: 25 mm, 40 mm, 50 mm center-to-center |

| Opções de superfície | Gritted surface (anti-slip) Superfície lisa Covered surface (solid top) |

| Colors Available | Yellow (most common) Verde Grey Red Customized colors upon request |

| Common Resin Types | Isophthalic Polyester (standard corrosion resistance) Vinyl Ester (high chemical resistance) Phenolic (fire-resistant applications) |

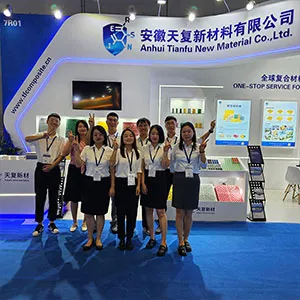

About the Factory

Anhui Tianfu New Material Co., Ltd is a leading professional manufacturer specializing in FRP moulded grating production. With over 20 years of experience in the composite materials industry, we are dedicated to delivering high-quality fiberglass reinforced plastic (FRP) solutions for a wide range of industrial and commercial applications. Our modern factory is equipped with advanced production lines, covering an area of more than 26,000 square meters. We offer a complete range of molded FRP gratings featuring superior strength, chemical resistance, fire retardancy, and anti-slip performance. At Tianfu New Material, we prioritize innovation, strict quality control, and customer satisfaction. Our products are certified to international standards and exported to over 30 countries worldwide, serving industries such as chemical plants, sewage treatment facilities, offshore platforms, and walkways. Whether you need standard sizes or customized solutions, Tianfu is your reliable partner for FRP moulded grating.

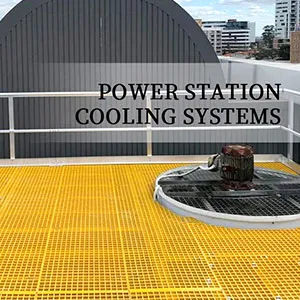

Cenários de Aplicação

About the Factory

We are a professional FRP Grating manufacturer with 20+ years of experience. Our 26,000㎡ factory is ISO9001 certified, serving clients across 30+ countries with OEM/ODM capability. We provide customized solutions and fast delivery worldwide.

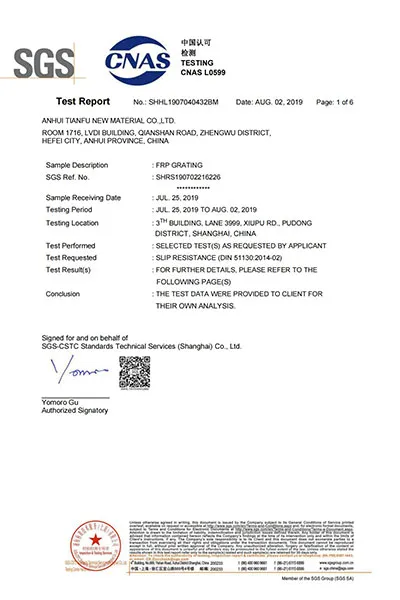

Our FRP gratings are manufactured in accordance with ISO 9001 standards and tested per ASTM E84 (Class 1 fire rating), ASTM D638/D790 for mechanical performance, and comply with BS 476 and EN 13706 standards. Third-party testing available through SGS and TUV upon request.

Exibição

JEC WORLD 2023

MUNDO JEC 2024

CAMX 2025

SHANGHAI 2025

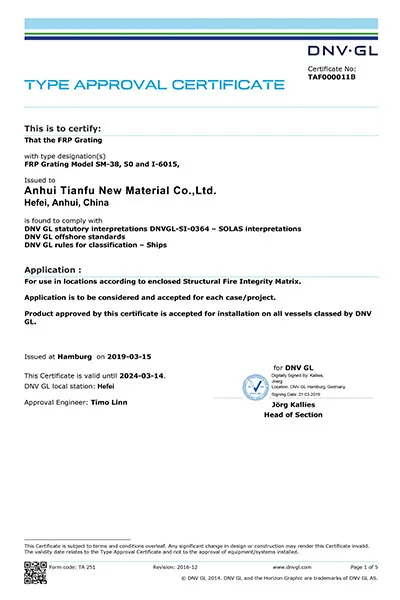

Certificate

Other Products

VR Factory Tour

FRP Water Tank

Series :

FRP Water Tank >aplicativo

Municipal Water Supply Systems Fire Water Storage Industrial Process Water Storage Rainwater Harvesting Agricultural Irrigation Portable Water for Residential Complexes Wastewater & Greywater Storage

Tensile Strength :

≥ 100–200 MPa

Flexural Strength :

≥ 250–300 MPa

Compressive Strength :

≥ 200–250 MPa

Elastic Modulus (Flexural) :

20–30 GPa

Impact Strength (Notched Izod) :

≥ 90 J/m

Hydrostatic Pressure Resistance :

Designed for pressure up to 10 bar or more

Perguntas frequentes

P:

What is an FRP water tank?

A :

An FRP (Fiberglass Reinforced Plastic) water tank is a durable, corrosion-resistant storage vessel made from composite materials—fiberglass reinforcement and a polymer resin matrix—designed to store potable or non-potable water in various industrial, commercial, or municipal applications.

P:

Is FRP suitable for drinking water storage?

A :

Yes, FRP tanks can be manufactured using NSF/ANSI 61-certified food-grade resins and linings, making them safe for storing drinking water and other clean water supplies.

P:

How long does an FRP water tank last?

A :

FRP water tanks typically have a service life of 20 to 30 years or more, depending on usage conditions, resin quality, UV exposure, and maintenance practices.

P:

What are the key advantages of FRP water tanks?

A :

Key benefits include: Corrosion resistance (no rusting) Lightweight and easy installation Low maintenance requirements Long lifespan Customizable design and size

P:

Can FRP water tanks withstand high temperatures or pressure?

A :

Yes, depending on the resin used, FRP tanks can handle operating temperatures up to 120°C and pressure ratings up to 10 bar or more with proper design.

P:

Are FRP tanks customizable?

A :

Absolutely. FRP water tanks can be tailored in terms of size, shape, color, inlet/outlet configuration, internal linings, and chemical resistance to meet project-specific requirements.

P:

Where are FRP water tanks commonly used?

A :

FRP tanks are used in a wide range of applications including: Municipal water supply Rainwater harvesting Fire water storage Agricultural irrigation Industrial process water Residential water systems

Outros produtos relacionados