การแนะนำประสิทธิภาพของผลิตภัณฑ์

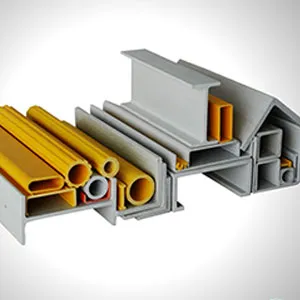

FRP Sheets (Fiber Reinforced Polymer Sheets) are flat composite panels made from a combination of reinforcing fibers—typically glass fiber (E-glass)—and a polymer resin matrix such as polyester, vinyl ester, or epoxy. These sheets are known for their high strength, lightweight nature, corrosion resistance, and versatility, making them suitable for a wide range of industrial, commercial, and structural applications.

FRP sheets are produced through manufacturing methods such as hand lay-up, การขึ้นรูปโดยการอัด, หรือ continuous lamination, depending on thickness, finish, and application needs. They can be manufactured in various sizes, thicknesses (typically ranging from 1 mm to 25 mm), and surface finishes—smooth, textured, or anti-slip.

These sheets are widely used in:

- Wall and ceiling cladding in commercial kitchens, bathrooms, clean rooms, and cold storage

- Lining and protection of chemical tanks and pipelines

- Electrical insulation panels

- Roofing sheets for industrial buildings

- Marine panels และ transport flooring

Key Advantages:

- Corrosion resistant: Ideal for chemically aggressive environments

- Moisture and water-resistant

- Lightweight yet strong

- UV and weather resistant (when coated or formulated with UV inhibitors)

- Low maintenance and easy to clean

- Non-conductive and thermally insulating

- Can be cut and drilled easily on-site

In terms of customization, FRP sheets can be fire-retardant, color-pigmented, embossed, หรือ เคลือบ with gel coats or anti-slip surfaces. They can also be laminated with foam or honeycomb cores for structural sandwich panels.

FRP Sheets Specifications & Technical Parameters

| คุณสมบัติ | Typical Values |

|---|---|

| ความหนาแน่น | 1.5 – 2.0 g/cm³ |

| ความต้านแรงดึง | 100 – 300 MPa |

| ความแข็งแรงในการดัดงอ | 150 – 350 MPa |

| ความแข็งแรงในการบีบอัด | 100 – 250 MPa |

| ทนต่อแรงกระแทก | High (Izod >20 kJ/m²) |

| Modulus of Elasticity | 7 – 25 GPa |

| Thermal Conductivity | 0.2 – 0.35 W/m·K (low – excellent insulation) |

| การนำไฟฟ้า | Non-conductive |

| Water Absorption | < 0.5% |

| Operating Temperature Range | -40°C to +120°C (higher available with special resins) |

| ความต้านทานการกัดกร่อน | Excellent (industrial-grade chemical resistance) |

| ทนไฟ | Flame-retardant grades available (ASTM E84 Class A) |

| ต้านทานรังสียูวี | High (when coated or using UV-resistant resin systems) |

FRP Sheets Technical Parameters

| คุณสมบัติ | Typical Values |

|---|---|

| ความหนาแน่น | 1.5 – 2.0 g/cm³ |

| ความต้านแรงดึง | 100 – 300 MPa |

| ความแข็งแรงในการดัดงอ | 150 – 350 MPa |

| ความแข็งแรงในการบีบอัด | 100 – 250 MPa |

| ทนต่อแรงกระแทก | High (Izod >20 kJ/m²) |

| Modulus of Elasticity | 7 – 25 GPa |

| Thermal Conductivity | 0.2 – 0.35 W/m·K (low – excellent insulation) |

| การนำไฟฟ้า | Non-conductive |

| Water Absorption | < 0.5% |

| Operating Temperature Range | -40°C to +120°C (higher available with special resins) |

| ความต้านทานการกัดกร่อน | Excellent (industrial-grade chemical resistance) |

| ทนไฟ | Flame-retardant grades available (ASTM E84 Class A) |

| ต้านทานรังสียูวี | High (when coated or using UV-resistant resin systems) |

Why Choose Us

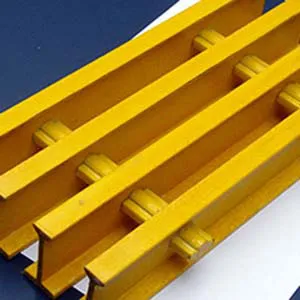

Expertise in FRP Grating Manufacturing

With over 20 years of experience, our factory specializes exclusively in the design, development, and production of high-performance FRP (Fiberglass Reinforced Plastic) gratings. Our deep industry knowledge ensures that every product meets the most demanding industrial standards.

Advanced Technology and Equipment

We utilize state-of-the-art manufacturing equipment and precision molding technology to produce gratings with superior strength, corrosion resistance, and dimensional accuracy. Our commitment to innovation means your project benefits from the latest advancements in FRP technology.

Customized Solutions

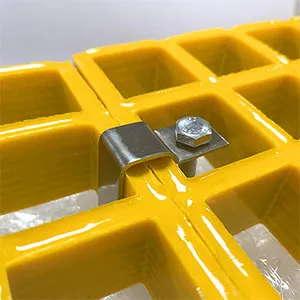

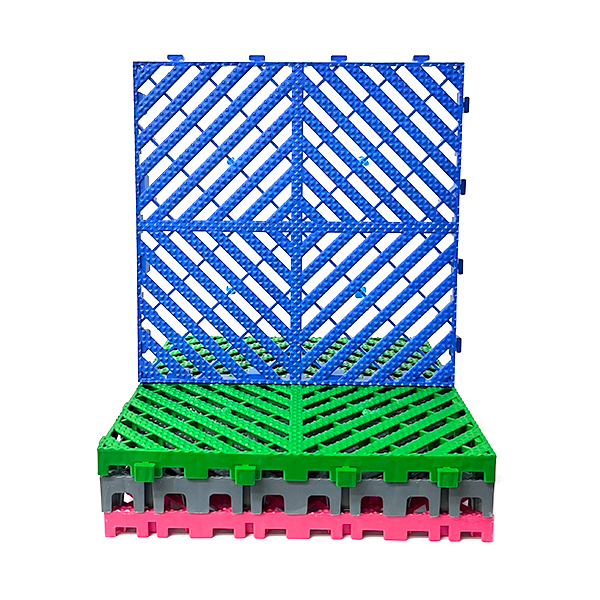

From panel sizes and resin types to surface finishes and colors, we offer complete customization to meet your unique application needs—be it industrial flooring, stair treads, trench covers, or marine platforms.

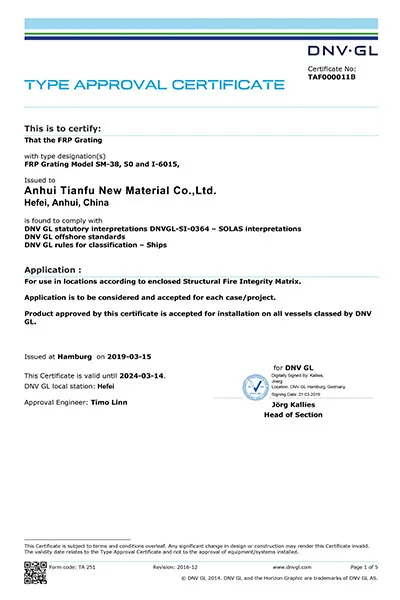

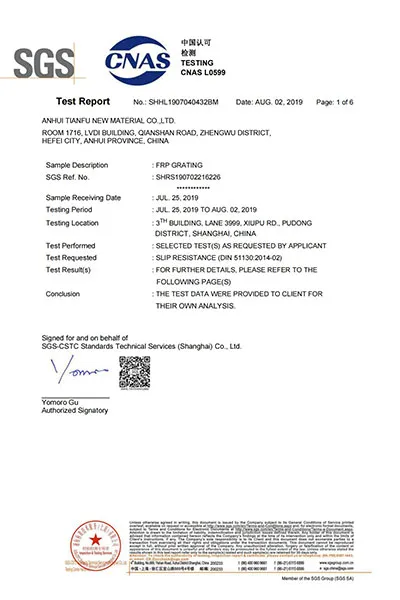

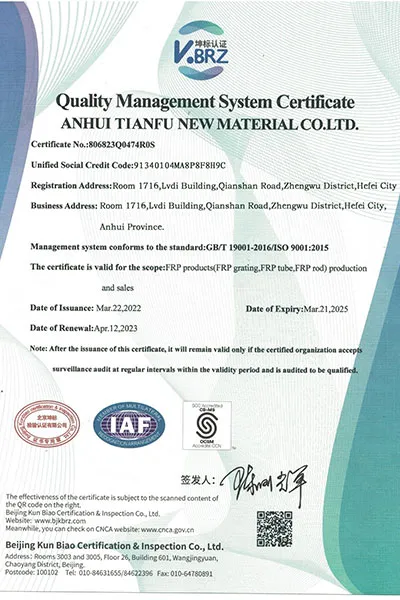

Stringent Quality Control

Every product undergoes a rigorous quality inspection process, including load testing, flame retardance checks, and corrosion resistance analysis. Our ISO-certified quality management system ensures consistent excellence in every batch.

Competitive Pricing

We offer factory-direct pricing without compromising on quality. With optimized production processes and bulk manufacturing capabilities, we help our customers achieve cost savings at scale.

Reliable Delivery and Global Reach

We maintain a large stock of standard products and operate a streamlined logistics system, ensuring fast delivery times locally and internationally. We’ve successfully served clients in over 15 countries.

Hot-Selling Products

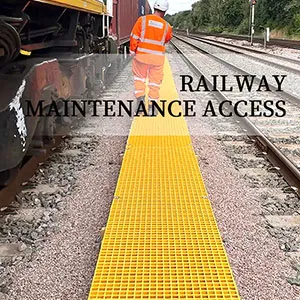

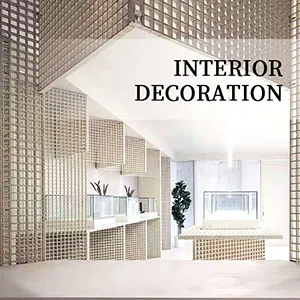

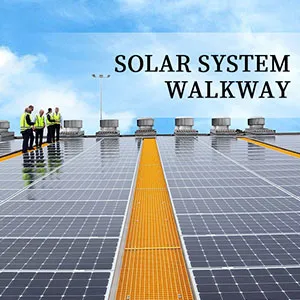

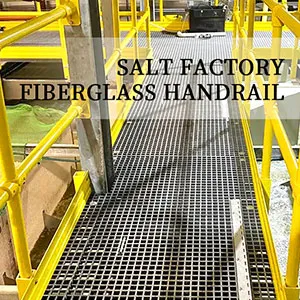

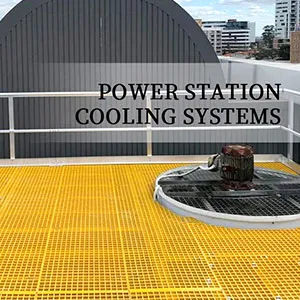

Application Scenarios

About the Factory

We are a professional FRP Grating manufacturer with 20+ years of experience. Our 26,000㎡ factory is ISO9001 certified, serving clients across 30+ countries with OEM/ODM capability. We provide customized solutions and fast delivery worldwide.

Our FRP gratings are manufactured in accordance with ISO 9001 standards and tested per ASTM E84 (Class 1 fire rating), ASTM D638/D790 for mechanical performance, and comply with BS 476 and EN 13706 standards. Third-party testing available through SGS and TUV upon request.

นิทรรศการ

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

Certificate

Other Products

VR Factory Tour

FRP Sheets

ชุด :

สินค้า >แอปพลิเคชัน

Wall and ceiling cladding in commercial kitchens, bathrooms, clean rooms, and cold storage Lining and protection of chemical tanks and pipelines Electrical insulation panels Roofing sheets for industrial buildings Marine panels and transport flooring

Material Composition :

Glass fiber reinforcement + Polyester, Vinyl Ester, or Epoxy resin

Manufacturing Methods :

Hand Lay-up, Continuous Lamination, Compression Molding

Available Thickness :

1 mm – 25 mm (custom options up to 50 mm available)

Sheet Sizes :

Standard: 1220 mm x 2440 mm (4 ft x 8 ft); custom lengths up to 3660 mm or longer

Standard Lengths :

3 m, 6 m, or custom up to 12 m

Surface Finish :

Smooth, Textured, Glossy, Matte, Embossed, Anti-slip, Gel-coated

Colors Available :

White, Grey, Green, Blue, Yellow, Custom (UV-stabilized colors available)

Reinforcement Type :

E-glass fiber (woven roving, chopped strand mat, or combination)

คำถามที่พบบ่อย

ถาม :

What are FRP Sheets?

ตอบ :

FRP sheets are composite panels made from glass fiber reinforcement embedded in a polymer resin matrix (such as polyester, vinyl ester, or epoxy). They are strong, lightweight, corrosion-resistant, and used for protective and structural applications.

ถาม :

What are the common applications of FRP Sheets?

ตอบ :

Wall and ceiling cladding (kitchens, clean rooms, cold storage) Roofing panels Lining for chemical tanks and ducts Electrical insulation Marine flooring and vehicle interiors Anti-corrosion surface panels

ถาม :

What sizes and thicknesses are available?

ตอบ :

Standard sizes: 1220 x 2440 mm (4 ft x 8 ft) Thickness: 1 mm to 25 mm, custom up to 50 mm Custom sizes and shapes are also available on request.

ถาม :

Are FRP Sheets waterproof?

ตอบ :

Yes. FRP sheets are non-porous and fully waterproof, making them ideal for wet environments and hygienic applications.

ถาม :

Do FRP Sheets resist corrosion and chemicals?

ตอบ :

Yes. They are highly resistant to a wide range of chemicals including acids, alkalis, and solvents—making them perfect for harsh industrial settings.

ถาม :

Are FRP Sheets fire-resistant?

ตอบ :

Fire-retardant versions are available and can meet standards like ASTM E84 Class A or UL 94 V-0, depending on the resin used.

ถาม :

Can FRP Sheets be used outdoors?

ตอบ :

Yes. UV-resistant FRP sheets or sheets with protective gel coats are suitable for prolonged outdoor exposure without degradation.

ถาม :

How are FRP Sheets installed or fixed?

ตอบ :

They can be installed using adhesives, mechanical fasteners (screws, rivets), or a combination of both, depending on the surface and application.

สินค้าอื่นๆที่เกี่ยวข้อง