产品性能介绍

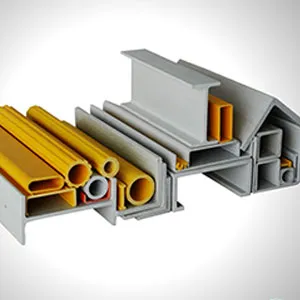

FRP结构型材 (也称为FRP结构型材或玻璃纤维增强塑料结构构件)是由玻璃纤维增强材料和热固性树脂通过一种称为FRP的工艺组合而成的工程复合材料部件。 拉挤. 这些型材旨在取代钢、铝或木材等传统材料,用于对耐腐蚀性、轻质和低维护性要求较高的结构应用。.

制造过程

采用以下方法制造FRP结构型材 拉挤 工艺流程如下:将连续玻璃纤维粗纱、毡片和薄纱浸渍树脂体系(例如聚酯、乙烯基酯、环氧树脂或酚醛树脂),然后拉过加热模具,形成特定的横截面形状。最终产品具有高强度、尺寸稳定性好、耐腐蚀等优异的结构型材。.

常见的FRP结构型材类型

可生产多种型材以满足不同的设计和工程需求。常见的FRP型材包括:

- 角度(L)

- 工字钢

- 宽翼缘梁(WF梁)

- 通道(C通道、U通道)

- 方形管

- 矩形管

- 圆管

- 平板

- 棒材或实心圆棒

- 踢脚板和扶手组件

每个型材的壁厚、尺寸和树脂体系均可定制,以满足特定的结构和环境要求。.

FRP结构型材的优势

- 耐腐蚀性能:FRP 形状不受化学品、盐水、酸和湿气的锈蚀、腐烂和腐蚀,因此非常适合在污水处理厂、海洋结构和化学加工设施等腐蚀性环境中使用。.

- 轻的FRP型材的重量比钢材轻约751吨,比铝材轻约301吨。这使得它们更容易运输、搬运和安装,从而降低了人工成本,并省去了使用重型起重设备的需求。.

- 高强度重量比尽管重量轻,FRP结构件仍具有令人印象深刻的机械强度和刚度,能够在最小变形的情况下承受相当大的载荷。.

- 电气和隔热与金属不同,FRP 不导电也不导热,因此是电气装置和隔热应用的安全选择。.

- 低维护:FRP结构无需涂漆、镀锌或保护涂层。它们具有抗紫外线性能(添加适当添加剂后),并且只需极少的维护即可长期保持强度和外观。.

- 非磁性且电磁干扰透明非常适合在雷达装置或核磁共振室等敏感环境中使用,在这些环境中必须避免金属干扰。.

FRP结构型材的应用

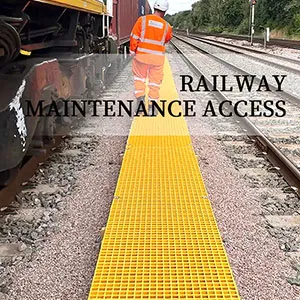

- 平台、走道和楼梯支撑

- 电缆桥架和电气支架

- 化学品储罐支架和框架

- 冷却塔和暖通空调结构

- 海洋和近海工程

- 建筑元素(顶篷、凉棚、围栏)

- 标牌和照明杆

- 桥梁和结构改造

FRP结构型材规格及技术参数

1. 材料组成

- 加强:连续E玻璃纤维粗纱、缝合毡和表面薄纱

- 树脂系统:

- 间苯二甲酸聚酯 – 一般耐腐蚀性

- 乙烯基酯 – 优异的耐化学性和耐腐蚀性

- 酚醛型 – 高耐火性

- 环氧树脂 – 优异的机械性能

- 添加剂紫外线抑制剂、阻燃剂、着色颜料(可选)

2. 可用个人资料

| 形状类型 | 典型尺寸(毫米) |

|---|---|

| 角度(L) | 38 × 38 × 6 到 152 × 152 × 13 |

| 频道(C) | 50 × 25 × 6 至 203 × 76 × 9 |

| 工字钢 | 76 × 76 × 6 至 305 × 152 × 13 |

| 宽翼缘梁 | 102 × 102 × 6 至 305 × 152 × 13 |

| 方形管 | 38 × 38 × 6 到 152 × 152 × 13 |

| 矩形管 | 76 × 38 × 6 至 203 × 102 × 13 |

| 圆管 | 外径 25 至 152 毫米(壁厚 3–8 毫米) |

| 平板 | 厚度为 3 毫米至 25 毫米 |

| 实心圆棒 | 直径 10 至 50 毫米 |

3. 机械性能

| 财产 | 价值观 | 测试方法 |

|---|---|---|

| 抗拉强度 | ≥ 200 兆帕 | ASTM D638 |

| 拉伸模量 | ≥ 17 GPa | ASTM D638 |

| 抗弯强度 | ≥ 300 兆帕 | ASTM D790 |

| 弯曲模量 | ≥ 20 GPa | ASTM D790 |

| 抗压强度 | ≥ 250 兆帕 | ASTM D695 |

| 压缩模量 | ≥ 22 GPa | ASTM D695 |

| 剪切强度 | ≥ 50 兆帕 | ASTM D5379 |

| 抗冲击性(Izod) | ≥ 100 J/m | ASTM D256 |

| 承载能力 | ≥ 700 兆帕 | ASTM D5961 |

4.物理性质

| 财产 | 价值观 |

|---|---|

| 密度 | 1.7 – 2.0 克/立方厘米 |

| 热膨胀系数 | 约 1.2 × 10⁻⁵ /°C |

| 工作温度范围 | -50°C 至 +120°C(取决于树脂) |

| 吸水率(24小时) | < 0.5% |

| 抗紫外线 | (含抑制剂) |

| 电导率 | 非导电性 |

5.火灾和烟雾性能 (可选阻燃等级)

| 财产 | 价值观 |

|---|---|

| 可燃性(ASTM D635) | 自熄(燃烧时间<10秒) |

| 火焰蔓延指数(ASTM E84) | 1 类(≤ 25) |

| 烟密度(ASTM E662) | ≤ 450 |

6.饰面和选项

颜色标准颜色:灰色、绿色、黄色;可根据要求定制颜色

表面处理光滑、粗糙或防紫外线

連接钻孔、斜接端或预制组件

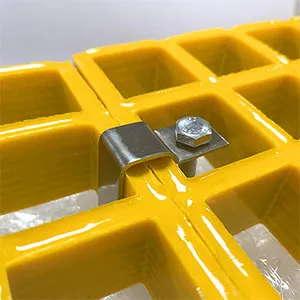

附加组件:FRP连接器、螺栓、不锈钢紧固件、密封盖

为什么选择我们

在FRP格栅制造方面拥有专业技术

我们工厂拥有超过20年的经验,专注于高性能FRP(玻璃纤维增强塑料)格栅的设计、开发和生产。我们深厚的行业知识确保每一件产品都符合最严格的行业标准。.

先进技术和设备

我们采用最先进的制造设备和精密成型技术,生产出强度高、耐腐蚀性强、尺寸精度高的格栅。我们致力于创新,这意味着您的项目将受益于FRP技术的最新进展。.

定制化解决方案

从面板尺寸和树脂类型到表面处理和颜色,我们提供全面的定制服务,以满足您独特的应用需求——无论是工业地板、楼梯踏板、沟槽盖板还是海洋平台。.

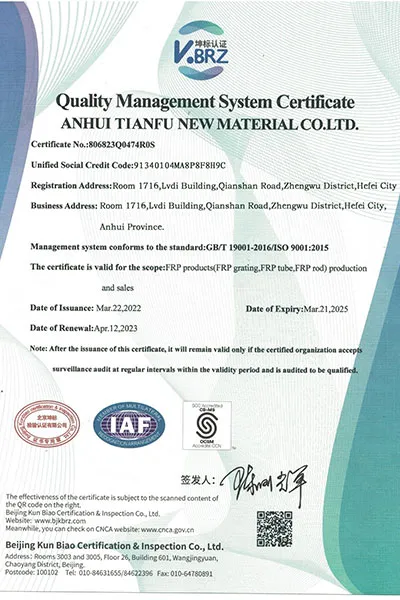

严格的质量控制

每件产品都经过严格的质量检验流程,包括负载测试、阻燃性测试和耐腐蚀性分析。我们通过 ISO 认证的质量管理体系确保每一批产品都品质始终如一。.

具有竞争力的价格

我们提供厂家直销价格,同时保证产品质量。凭借优化的生产流程和批量生产能力,我们帮助客户大规模降低成本。.

可靠的交付和全球覆盖

我们备有大量标准产品库存,并采用高效的物流系统,确保本地和国际市场的快速交付。我们已成功为超过15个国家的客户提供服务。.

热销产品

| 标准面板尺寸 | 1220 毫米 × 3660 毫米(4 英尺 × 12 英尺) 1220 毫米 × 4000 毫米(4 英尺 × 13.1 英尺) 915 毫米 × 3050 毫米(3 英尺 × 10 英尺) 1000 毫米 × 3000 毫米(可定制) (其他尺寸可根据项目需求定制) |

| 厚度选项 | 25 毫米(1 英寸) 30 毫米(1.2 英寸) 38 毫米(1.5 英寸)——最常见 50 毫米(2 英寸) |

| 网眼尺寸(开口尺寸) | 38 毫米 × 38 毫米(1.5 英寸 × 1.5 英寸)— 标准 40 毫米 × 40 毫米 19 毫米 × 19 毫米(用于防止小物体通过的微型网眼) |

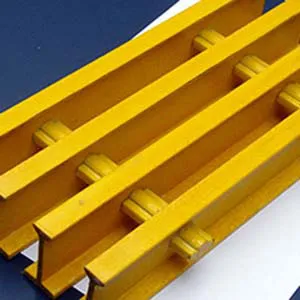

| 荷载杆宽度和间距 (适用于拉挤成型格栅) | 承重杆宽度:通常为 25 毫米、38 毫米、50 毫米 载荷杆间距:中心距 25 毫米、40 毫米、50 毫米 |

| 表面选项 | 表面有颗粒(防滑) 光滑的表面 覆盖表面(实心顶面) |

| 可选颜色 | 黄色(最常见) 绿色的 灰色的 红色的 可根据要求定制颜色 |

| 常见树脂类型 | 间苯二甲酸聚酯(标准耐腐蚀性) 乙烯基酯(耐化学性强) 酚醛树脂(耐火应用) |

关于工厂

安徽天福新材料有限公司 是一家领先的专业制造商,专门从事 FRP模压格栅 生产制造。凭借20余年的复合材料行业经验,我们致力于为广泛的工业和商业应用提供高品质的玻璃纤维增强塑料(FRP)解决方案。我们拥有现代化的工厂,配备先进的生产线,占地面积超过26,000平方米。我们提供全系列模压FRP格栅,具有卓越的强度、耐化学腐蚀性、阻燃性和防滑性能。在天福新材料,我们始终将创新、严格的质量控制和客户满意度放在首位。我们的产品通过了国际标准认证,并出口到全球30多个国家,服务于化工厂、污水处理厂、海上平台和人行道等行业。无论您需要标准尺寸还是定制解决方案,天福都是您值得信赖的FRP模压格栅合作伙伴。.

推荐使用场合

关于工厂

我们是一家拥有20多年经验的专业FRP格栅制造商。我们拥有26,000平方米的工厂,并通过了ISO9001认证,为30多个国家的客户提供OEM/ODM服务。我们提供定制化解决方案,并可快速交付至全球各地。.

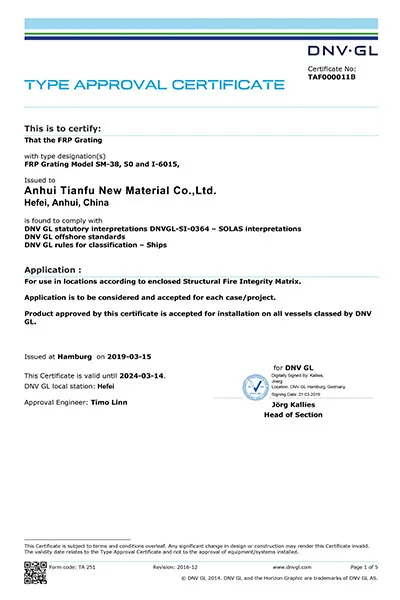

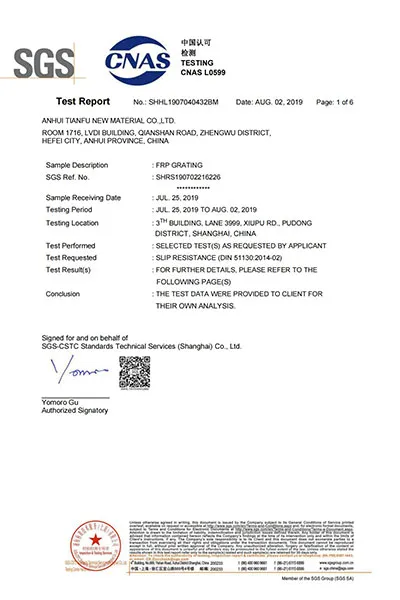

我们的FRP格栅按照ISO 9001标准生产,并根据ASTM E84(1级防火等级)和ASTM D638/D790进行机械性能测试,符合BS 476和EN 13706标准。可根据要求提供SGS和TUV的第三方测试报告。.

展览

2023年JEC世界博览会

JEC 世界 2024

CAMX 2025

上海2025

证书

其他产品

VR工厂参观

FRP结构型材

系列 :

玻璃纤维拉挤型材 >应用场景

工业地板、海洋及海上平台、污水处理厂、食品饮料行业、交通基础设施、建筑工地、电池室及变电站、公共及商业空间、水上乐园及游泳池、屋顶及暖通空调系统

角度(L):

典型尺寸(毫米):38 × 38 × 6 至 152 × 152 × 13

频道(C):

典型尺寸(毫米):50 × 25 × 6 至 203 × 76 × 9

工字钢:

典型尺寸(毫米):76 × 76 × 6 至 305 × 152 × 13

宽翼缘梁:

典型尺寸(毫米):102 × 102 × 6 至 305 × 152 × 13

方管:

典型尺寸(毫米):38 × 38 × 6 至 152 × 152 × 13

矩形管:

典型尺寸(毫米):76 × 38 × 6 至 203 × 102 × 13

常问问题

问:

有哪些安全性能可保证的表面处理?

答 :

FRP拉挤成型的格栅可以制成带砂粒(防滑)表面、凹面顶部,甚至带盖板,以增强防滑性和工人安全。.

其他相关产品