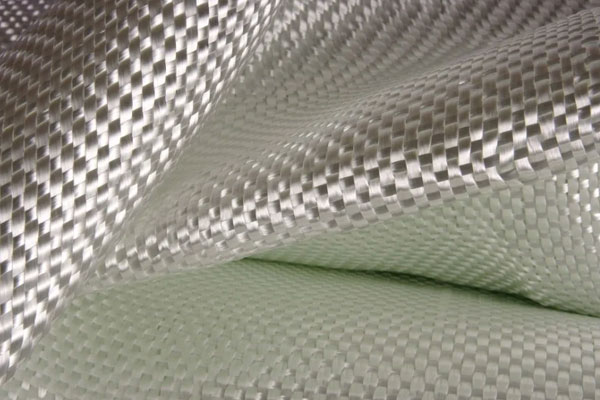

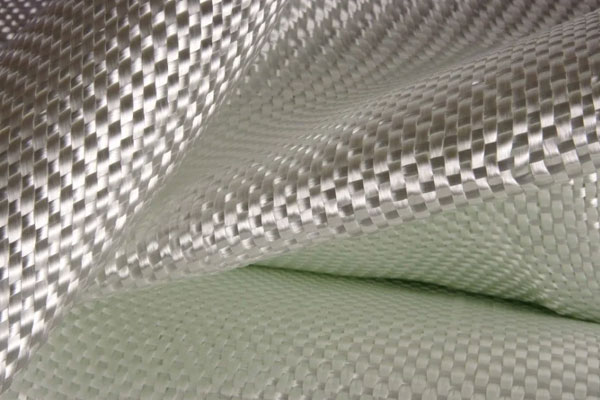

قماش منسوج من الألياف الزجاجية هي مادة نسيجية عالية الأداء مصنوعة من حزم متشابكة من خيوط زجاجية متصلة. وتُستخدم على نطاق واسع في مجموعة كبيرة من الصناعات نظرًا لنسبة قوتها إلى وزنها الاستثنائية، وثبات أبعادها، ومقاومتها للحرارة والتآكل الكيميائي.

مقدمة عن أداء المنتج

يتم تصنيع قماش الألياف الزجاجية من خلال تقنيات النسيج الدقيقة، وهو متوفر بأوزان وأنواع نسيج وتشطيبات متنوعة، مما يسمح بحلول قابلة للتخصيص بدرجة عالية في الصناعات التي تتراوح من صناعة الطيران والفضاء إلى البناء والبحرية والإلكترونيات والسيارات.

2. 🎯 التطبيقات الرئيسية

يُستخدم القماش المنسوج من الألياف الزجاجية كوسيط تقوية أو طبقة عازلة في:

-

تصنيع المواد المركبة (على سبيل المثال، ألواح الألياف الزجاجية المقواة بالبلاستيك، والأنابيب، والخزانات، والقوارب)

-

العزل الكهربائي (تغليف المحول، ركيزة لوحة الدوائر المطبوعة)

-

العزل الحراري (دروع حرارية واقية، بطانات حجرة المحرك)

-

بناء (أغشية التسقيف، تقوية الجص، ألواح الجدران)

-

الفضاء والطيران (ألواح داخلية للطائرة، قنوات تهوية، أغطية انسيابية)

-

السيارات (ألياف الكربون الهجينة المشبعة مسبقًا، واقيات كاتم الصوت)

-

الحماية من التآكل (أغلفة داخلية للخزانات والأنابيب الفولاذية)

3. 🛠️ مميزات المنتج ومزاياه

| ميزة | وصف |

|---|---|

| نسبة عالية من القوة إلى الوزن | مثالي لتقوية الهياكل دون إضافة حجم كبير |

| ثبات أبعاد ممتاز | يحافظ على شكله تحت ضغط حراري أو ميكانيكي عالٍ |

| المقاومة الحرارية | يعمل بكفاءة في درجات حرارة تصل إلى 550 درجة مئوية (حسب النوع). |

| مقاومة كيميائية | يقاوم الأحماض والقلويات والمذيبات والرطوبة |

| العزل الكهربائي | يتميز بقوة عزل كهربائي عالية وموصلية منخفضة |

| الحرائق | غير قابل للاحتراق بطبيعته؛ يفي بمعايير مقاومة اللهب |

| مقاومة للأشعة فوق البنفسجية والعوامل الجوية | مناسب للتعرض الخارجي طويل الأمد مع التشطيبات المناسبة. |

| تعدد الاستخدامات | متوافق مع البوليستر، والفينيل إستر، والإيبوكسي، والفينول، والراتنجات الأخرى |

4. 🔍 ورقة البيانات الفنية (TDS)

| ملكية | القيمة (النموذجية) | طريقة اختبار |

|---|---|---|

| نوع الألياف | زجاج إلكتروني | – |

| نمط النسيج | سادة / مائل / ساتان | – |

| نوع الخيط | EC9 / DE75 / DE110، إلخ. | – |

| وزن القماش | 200 – 1200 غ/م² | ASTM D3776 |

| سماكة | 0.1 – 1.5 مم | ASTM D1777 |

| قوة الشد (السدى/اللحمة) | 300 – 900 نيوتن/25 مم | ASTM D5035 |

| الاستطالة عند نقطة الكسر | < 4% | ASTM D5035 |

| محتوى الرطوبة | ≤ 0.2% | ASTM D4029 |

| درجة حرارة التشغيل | من -100 درجة مئوية إلى +550 درجة مئوية | – |

| قوة العزل الكهربائي | ≥ 6 كيلو فولت/مم | ASTM D149 |

| توافق الراتنج | بوليستر، إيبوكسي، فينولي، فينيل إستر | – |

| مقاومة اللهب | زجاج إلكتروني ذاتي الإطفاء | متوافق مع معيار UL 94 V0 |

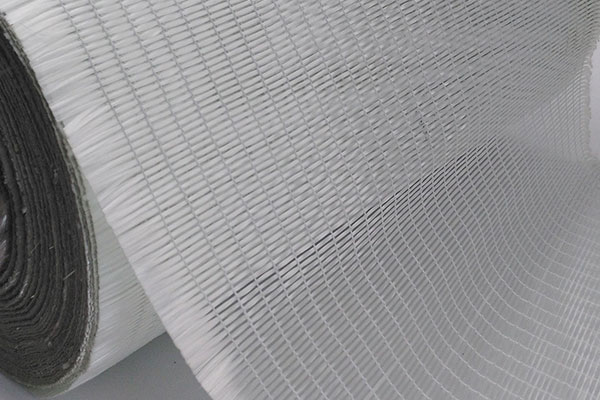

| عرض اللفة القياسي | 1000 مم / 1250 مم / 2000 مم | – |

| طول اللفة | قابل للتخصيص (عادةً 50-200 متر) | – |

5. 🧬 أنماط النسيج المتاحة

-

نسيج سادة

-

نمط متشابك فوق وتحت

-

أكثر الهياكل استقرارًا وتوازنًا

-

سهولة الاستخدام وقلة التلف

-

-

نسيج قطني مائل

-

نمط قطري

-

مرن وقابل للطي

-

شائع في أشكال القوالب المعقدة

-

-

نسيج الساتان (مثلاً، 4H/8H)

-

نعومة سطح عالية

-

راحة جيدة

-

مفضل للاستخدامات التجميلية

-

6. مقارنة بين قماش الألياف الزجاجية والمواد الأخرى

| ملكية | قماش من الألياف الزجاجية | قماش ألياف الكربون | قماش كيفلر | صفائح الألمنيوم |

|---|---|---|---|---|

| القوة/الوزن | عالي | عالي جدا | عالي | واسطة |

| المقاومة الحرارية | عالي | واسطة | واسطة | قليل |

| يكلف | معتدل | عالي | عالي | قليل |

| العزل الكهربائي | ممتاز | موصل | جيد | موصل |

| مقاومة كيميائية | ممتاز | معتدل | ممتاز | فقير |

| قابلية الاحتراق | غير قابل للاشتعال | قابل للاشتعال | غير قابل للاشتعال | قابل للاشتعال |

7. 🧊 توصيات التخزين والمناولة

-

يُحفظ في بيئة جافة وباردة (15-30 درجة مئوية)

-

تجنب التعرض المباشر للأشعة فوق البنفسجية والرطوبة

-

يُحفظ في عبوته الأصلية حتى الاستخدام

-

استخدم القفازات لمنع تهيج الجلد

-

استخدم شفرات حادة أو قواطع دوارة للحصول على حواف نظيفة

8. 🧪 تشريب الراتنج والتصفيح

يمكن استخدام قماش الألياف الزجاجية مع:

-

وضع يدوي أو رش

-

تقنية الحقن الفراغي (VARTM)

-

عملية السحب / لف الخيوط

-

التغليف المسبق التشريب (باستخدام الإيبوكسي في المرحلة الثانية)

يمكن لنظام الراتنج أن يؤثر بشكل كبير على خصائص القطعة النهائية. وللاستخدام في درجات الحرارة العالية، يُنصح باستخدام أنظمة الإيبوكسي أو الفينول.

9. ⚠️ ملاحظات السلامة

-

يُرجى التعامل بحرص لتجنب ملامسة الجلد أو الألياف المحمولة جواً

-

استخدم معدات الوقاية الشخصية المناسبة (القفازات، النظارات الواقية، قناع الغبار)

-

قم بالقطع في منطقة جيدة التهوية أو تحت نظام شفط الهواء

-

لا تقم بحرق أو إحراق قماش الألياف الزجاجية (قد تذوب خيوط الزجاج وتتبخر الراتنج).

10. 📦 خيارات التغليف

-

لفائف ورق كرافت

-

غشاء البولي إيثيلين مع أكياس مجففة

-

معبأة على منصات نقالة مع واقيات للحواف

-

ملصقات مخصصة مع تتبع الدفعات والمواصفات

11. ❓ الأسئلة الشائعة

س1: هل يمكن استخدام قماش الألياف الزجاجية في الهواء الطلق؟

نعم، مع استخدام مادة الراتنج المناسبة أو الطلاء المقاوم للأشعة فوق البنفسجية، فإنه يعمل بشكل جيد في ظل التعرض للعوامل الجوية.

س2: هل قماش الألياف الزجاجية مقاوم للماء؟

تتميز خيوط الزجاج نفسها بأنها خاملة ومقاومة للرطوبة. ومع ذلك، فإن النسيج ككل لا يشكل حاجزًا للبخار إلا إذا تم تشريبه بالراتنج.

س٣: هل يمكن طلاؤه؟

نعم. بعد تصلب الراتنج، يمكن صنفرة الطبقة الرقيقة وطلائها باستخدام طلاءات متوافقة.

س4: ما هي مدة الصلاحية؟

عند تخزينها بشكل صحيح، تتمتع الأقمشة المنسوجة من الألياف الزجاجية بفترة صلاحية غير محددة. أما الأنواع المصنوعة من الإيبوكسي المشرب مسبقًا، فتتراوح فترة صلاحيتها عادةً بين 6 و12 شهرًا، وذلك حسب ظروف التخزين.

قماش منسوج من الألياف الزجاجية

مسلسل :

نسيج الألياف الزجاجية >طلب

صناعة الطيران: تُستخدم في الهياكل المركبة خفيفة الوزن مثل الأجنحة وأجزاء جسم الطائرة والمكونات الداخلية. صناعة السيارات: تُستخدم أقمشة الألياف الزجاجية المخيطة في ألواح الهيكل والهياكل المقواة والمكونات الهيكلية الأخرى في صناعة السيارات. الصناعات البحرية: مثالية للاستخدام في هياكل القوارب والأسطح وغيرها من الهياكل البحرية حيث تُعد القوة ومقاومة الماء والتآكل من العوامل الحاسمة. طاقة الرياح: تُستخدم في صناعة شفرات توربينات الرياح، حيث تُعد القوة العالية والوزن الخفيف من المتطلبات الأساسية. المعدات الرياضية: تُستخدم لتقوية المعدات مثل إطارات الدراجات وعصي التزلج وألواح التزلج على الجليد. البناء: تُستخدم لتقوية الهياكل الخرسانية أو مواد البناء المركبة الأخرى.

اسم العلامة التجارية :

TF مركب

اسم المنتج :

قماش منسوج من الألياف الزجاجية

التعليمات

س:

هل يمكن قص القماش المنسوج من الألياف الزجاجية بأطوال أو أشكال مخصصة؟

أ :

نعم. يمكن تخصيص قماش الألياف الزجاجية بسهولة باستخدام آلات القطع الصناعية، أو قواطع الليزر، أو التشذيب اليدوي. وللحصول على متطلبات عالية الدقة (مثل تطبيقات لوحات الدوائر المطبوعة أو تطبيقات الفضاء)، يُنصح باستخدام القطع بنفث الماء أو القطع باستخدام الحاسوب (CNC). كما يمكن للمصنعين توفير لفائف بعرض مخصص عند الطلب.

س:

هل قماش الألياف الزجاجية آمن للمس أو الاستخدام في البيئات الداخلية؟

أ :

نعم عموماً، ولكن قد يُسبب التعامل المباشر معه تهيجاً طفيفاً للجلد بسبب ألياف الزجاج الدقيقة. يُنصح بارتداء قفازات وقميص بأكمام طويلة. بمجرد تغليفه بالراتنج، يصبح المادة خاملة وآمنة للاستخدام في البيئات الداخلية والخارجية، بما في ذلك المساحات السكنية والتجارية.

س:

ما هو نظام الراتنج الأنسب للاستخدام مع الأقمشة المنسوجة من الألياف الزجاجية؟

أ :

يعتمد ذلك على التطبيق: بوليستر/فينيل إستر للمركبات العامة ومقاومة التآكل، إيبوكسي للتطبيقات عالية القوة، أو تطبيقات الفضاء، أو التطبيقات الكهربائية، فينولي لمقاومة الحريق والعزل الحراري. تأكد من التشبع الكامل والتوافق بين الراتنج ونسيج القماش.

س:

كيف يتصرف قماش الألياف الزجاجية في درجات الحرارة القصوى؟

أ :

يتحمل القماش المنسوج من الألياف الزجاجية التعرض المستمر لدرجات حرارة تصل إلى 550 درجة مئوية (1022 درجة فهرنهايت) في أنواع الألياف الزجاجية من النوع E. وللحصول على مقاومة أعلى، يُنصح باستخدام الألياف الزجاجية من النوع S أو القماش المصنوع من السيليكا. يحافظ هذا القماش على قوته وشكله حتى في ظل دورات التغير الحراري، مما يجعله مثاليًا لأنظمة مقاومة الحريق والعزل وأنظمة التهوية.

س:

هل يمكن إعادة استخدام أو تدوير القماش المنسوج من الألياف الزجاجية؟

أ :

بعد تشريبها بالراتنج وتصلبها، يصعب إعادة تدوير مركبات الألياف الزجاجية. مع ذلك، يمكن إعادة استخدام قصاصات قماش الألياف الزجاجية النظيفة وغير المستخدمة في أعمال الترقيع أو التقوية أو إنتاج الأجزاء المصبوبة. وتُبذل جهود متواصلة في هذا القطاع لتحسين طرق إعادة تدوير المركبات.

المنتجات الأخرى ذات الصلة