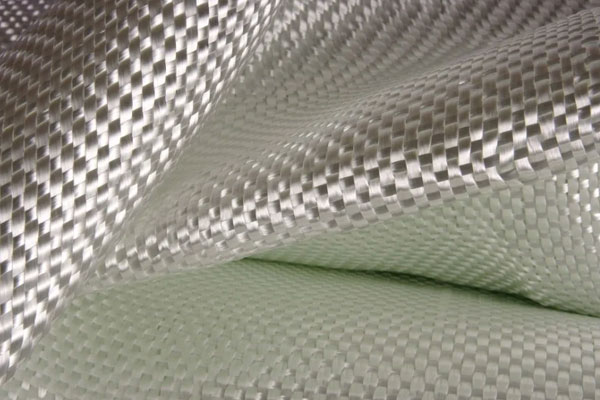

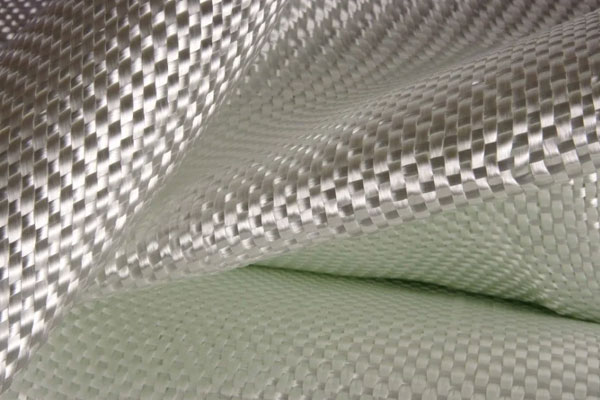

Fiberglass woven cloth is a high-performance textile material made from interlaced bundles of continuous glass filaments. It is widely used across a broad spectrum of industries for its exceptional strength-to-weight ratio, dimensional stability, and resistance to temperature and chemical attack.

Einführung zur Produktleistung

Manufactured through precision weaving techniques, fiberglass cloth is available in a variety of weights, weaves, and finishes, allowing for highly customizable solutions in industries ranging from aerospace to construction, marine, electronics, and automotive.

2. 🎯 Key Applications

Fiberglass woven cloth serves as a reinforcement medium or barrier layer in:

-

Composite Manufacturing (e.g., FRP panels, pipes, tanks, boats)

-

Elektrische Isolierung (transformer wrapping, PCB substrate)

-

Wärmedämmung (protective heat shields, engine bay liners)

-

Konstruktion (roofing membranes, plaster reinforcement, wall panels)

-

Aerospace and Aviation (aircraft interior panels, ducting, fairings)

-

Automobilindustrie (carbon-fiber hybrid prepregs, muffler shields)

-

Korrosionsschutz (liner wraps for steel tanks and pipes)

3. 🛠️ Product Features and Advantages

| Besonderheit | Beschreibung |

|---|---|

| Hohes Verhältnis von Festigkeit zu Gewicht | Ideal for structural reinforcement without adding bulk |

| Excellent Dimensional Stability | Maintains form under high thermal or mechanical stress |

| Thermischer Widerstand | Operates effectively at temperatures up to 550°C (depending on grade) |

| Chemische Resistenz | Resists acids, alkalis, solvents, and moisture |

| Elektrische Isolierung | Offers high dielectric strength and low conductivity |

| Feuerdämmend | Inherently non-combustible; meets flame resistance standards |

| UV and Weathering Resistance | Suitable for long-term outdoor exposure with appropriate finishes |

| Vielseitigkeit | Compatible with polyester, vinyl ester, epoxy, phenolic, and other resins |

4. 🔍 Technical Data Sheet (TDS)

| Eigentum | Wert (typisch) | Testmethode |

|---|---|---|

| Fasertyp | E-Glas | – |

| Weave Style | Plain / Twill / Satin | – |

| Yarn Type | EC9 / DE75 / DE110, etc. | – |

| Fabric Weight | 200 – 1200 g/m² | ASTM D3776 |

| Dicke | 0.1 – 1.5 mm | ASTM D1777 |

| Tensile Strength (Warp/Weft) | 300 – 900 N/25mm | ASTM D5035 |

| Dehnung beim Bruch | < 4% | ASTM D5035 |

| Feuchtigkeitsgehalt | ≤ 0,2% | ASTM D4029 |

| Betriebstemperatur | -100°C to +550°C | – |

| Electrical Dielectric Strength | ≥ 6 kV/mm | ASTM D149 |

| Harzkompatibilität | Polyester, Epoxy, Phenolic, Vinyl Ester | – |

| Flame Resistance | Self-extinguishing (E-glass) | UL 94 V0 compliant |

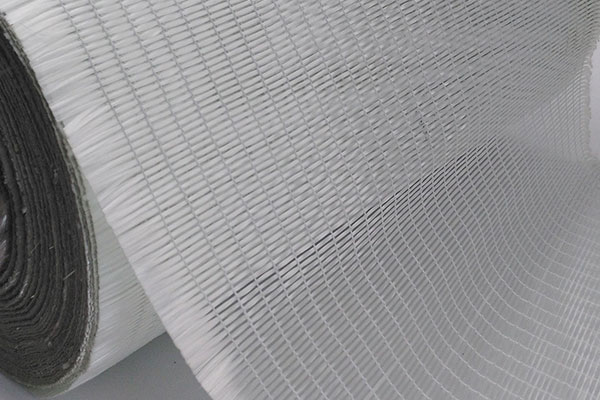

| Standard Roll Width | 1000 mm / 1250 mm / 2000 mm | – |

| Rollenlänge | Customizable (typically 50–200 m) | – |

5. 🧬 Available Weave Patterns

-

Plain Weave

-

Over-under interlacing pattern

-

Most stable and balanced structure

-

Easy handling and minimal fraying

-

-

Twill Weave

-

Diagonal pattern

-

Flexible and drapable

-

Common in complex mold shapes

-

-

Satin Weave (e.g., 4H/8H)

-

High surface smoothness

-

Good conformability

-

Preferred for cosmetic-grade applications

-

6. 🆚 Fiberglass Cloth vs. Other Materials

| Eigentum | Fiberglass Cloth | Carbon Fiber Cloth | Kevlar Cloth | Aluminum Sheet |

|---|---|---|---|---|

| Strength/Weight | Hoch | Sehr hoch | Hoch | Medium |

| Thermischer Widerstand | Hoch | Medium | Medium | Niedrig |

| Kosten | Mäßig | Hoch | Hoch | Niedrig |

| Elektrische Isolierung | Exzellent | Leitfähig | Gut | Leitfähig |

| Chemische Resistenz | Exzellent | Mäßig | Exzellent | Arm |

| Combustibility | Non-flammable | Flammable | Non-flammable | Flammable |

7. 🧊 Storage and Handling Recommendations

-

Store in dry, cool environment (15–30°C)

-

Avoid direct exposure to UV and moisture

-

Keep in original packaging until use

-

Use gloves to prevent skin irritation

-

Cut with sharp blades or rotary cutters for clean edges

8. 🧪 Resin Impregnation and Lamination

Fiberglass cloth can be used with:

-

Hand Lay-Up or Spray-Up

-

Vakuuminfusion (VARTM)

-

Pultrusion / Filament Winding

-

Prepreg Laminating (with B-stage epoxy)

The resin system can drastically influence final part properties. For high-temperature use, epoxy or phenolic systems are recommended.

9. ⚠️ Safety Notes

-

Handle with care to avoid skin contact or airborne fibers

-

Use appropriate PPE (gloves, goggles, dust mask)

-

Cut in well-ventilated area or under extraction

-

Do not burn or incinerate fiberglass cloth (glass filaments may melt and vaporize resin)

10. 📦 Packaging Options

-

Kraft paper rolls

-

PE film with desiccant packets

-

Palletized with edge protectors

-

Custom labels with lot tracking and specs

11. ❓ FAQ

Q1: Can fiberglass cloth be used outdoors?

Yes, with the right resin matrix or UV-resistant coating, it performs well under outdoor exposure.

Q2: Is fiberglass cloth waterproof?

The glass filaments themselves are inert and moisture-proof. However, the overall fabric is not a vapor barrier unless impregnated with resin.

Q3: Can it be painted?

Yes. After resin cure, the laminate can be sanded and painted using compatible coatings.

Q4: What’s the shelf life?

Stored properly, fiberglass woven cloth has an indefinite shelf life. However, epoxy prepreg versions typically have 6–12 months depending on storage conditions.

Glasfasergewebe

Serie :

Glasfasergewebe >Anwendung

Luft- und Raumfahrt: Verwendung in leichten Verbundstrukturen wie Tragflächen, Rumpfteilen und Innenausstattungen. Automobilindustrie: Vernähte Glasfasergewebe werden in Karosserieteilen, verstärkten Fahrgestellen und anderen Strukturbauteilen der Automobilindustrie eingesetzt. Schiffbau: Ideal für Bootsrümpfe, Decks und andere maritime Konstruktionen, bei denen Festigkeit sowie Wasser- und Korrosionsbeständigkeit entscheidend sind. Windenergie: Verwendung beim Bau von Windkraftanlagenflügeln, wo hohe Festigkeit und geringes Gewicht unerlässlich sind. Sportgeräte: Verwendung zur Verstärkung von Geräten wie Fahrradrahmen, Skistöcken und Snowboards. Bauwesen: Einsatz zur Verstärkung von Betonkonstruktionen oder anderen Verbundbaustoffen.

Markenname :

TF-Verbundwerkstoff

Produktname :

Glasfasergewebe

FAQ

Q :

Can fiberglass woven cloth be cut to custom widths or shapes?

A :

Yes. Fiberglass cloth can be easily customized using industrial slitters, laser cutters, or manual trimming. For high-precision needs (e.g., PCB or aerospace applications), waterjet or CNC cutting is recommended. Manufacturers can also deliver custom-width rolls upon request.

Q :

Is fiberglass cloth safe to touch or use in indoor environments?

A :

Generally yes, but direct handling can cause mild skin irritation due to fine glass fibers. It’s advisable to wear gloves and long sleeves. Once encapsulated in resin, the material becomes inert and safe for indoor and outdoor environments, including residential and commercial spaces.

Q :

What resin system works best with fiberglass woven cloth?

A :

t depends on the application: Polyester/Vinyl Ester for general-purpose composites and corrosion resistance Epoxy for high-strength, aerospace, or electrical applications Phenolic for fire resistance and thermal insulation Ensure full wet-out and compatibility between resin and cloth weave.

Q :

How does fiberglass cloth behave under extreme temperatures?

A :

Fiberglass woven cloth can withstand continuous exposure to temperatures up to 550°C (1022°F) for E-glass variants. For even higher resistance, S-glass or silica-based cloth is recommended. It retains strength and shape even under thermal cycling, making it ideal for fireproofing, insulation, or exhaust systems.

Q :

Can fiberglass woven cloth be reused or recycled?

A :

Once impregnated with resin and cured, fiberglass composites are not easily recyclable. However, clean, unused fiberglass cloth scraps can be reused in patching, reinforcement, or molded part production. Efforts are ongoing in the industry to enhance composite recycling methods.

Andere verwandte Produkte