Einführung zur Produktleistung

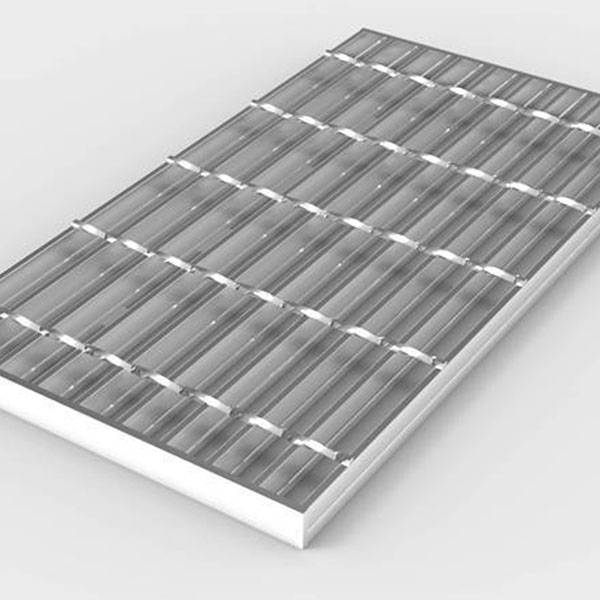

1. Introduction to Heavy Duty Steel Grating

Heavy-duty steel grating is designed to withstand extreme loads and harsh environmental conditions. It is widely used in industrial, commercial, and infrastructure applications where high strength and durability are essential. This type of grating is commonly found in highways, airports, docks, and heavy equipment areas, providing safety, structural integrity, and long-term performance.

2. Specifications of Heavy Duty Steel Grating

2.1 Types of Heavy Duty Steel Grating

Heavy-duty steel grating can be classified based on manufacturing techniques, load-bearing capacity, and application suitability.

1. Welded Heavy Duty Steel Grating

Welded heavy-duty steel grating is manufactured by fusing bearing bars and cross bars together using resistance welding, creating a strong, durable structure. It is the most common type used in industrial settings due to its cost-effectiveness and load-bearing capacity.

2. Press-Locked Heavy Duty Steel Grating

Press-locked grating is produced by mechanically pressing crossbars into bearing bars under high pressure, resulting in a tight and rigid structure. This type is often used in architectural applications where appearance and strength are equally important.

3. Riveted Heavy Duty Steel Grating

Riveted grating features bearing bars and crossbars connected through rivets, offering excellent load-bearing capabilities. It is ideal for bridge decks, industrial platforms, and areas with heavy vehicular traffic.

4. Swage-Locked Heavy Duty Steel Grating

Swage-locked grating is manufactured by inserting crossbars through pre-punched holes in bearing bars and then permanently locking them in place using a swaging process. It provides a strong, uniform, and smooth surface.

2.2 Materialzusammensetzung

-

Kohlenstoffstahl: Provides high strength and durability but requires galvanization or coating to prevent corrosion.

-

Galvanized Steel: Carbon steel coated with zinc to enhance corrosion resistance and longevity.

-

Stainless Steel: Used in corrosive environments due to its excellent resistance to oxidation and chemicals.

2.3 Oberflächenbehandlungen

-

Feuerverzinkung: Extends lifespan by preventing rust.

-

Pulverbeschichtung: Provides additional protection and aesthetic appeal.

-

Bare Steel: Used in applications where temporary grating is needed.

3. Abmessungen und Konfigurationen

3.1 Standard-Paneelgrößen

-

Breite: 600mm, 800mm, 1000mm, 1200mm, or custom sizes.

-

Länge: 1000mm, 1200mm, 1500mm, 2000mm, 3000mm, or tailored dimensions.

-

Dicke: Ranges from 3mm to 10mm, depending on load requirements.

3.2 Lagerstangenabstand

-

Standard Spacings: 19mm, 30mm, 40mm.

-

Heavy-Duty Options: 50mm and above for extreme load-bearing needs.

3.3 Querstangenabstand

-

Common Spacings: 38mm, 50mm, or customized.

3.4 Tragfähigkeiten

-

Designed to support loads ranging from 5000 kg/m² to over 20000 kg/m².

-

High-impact resistance suitable for heavy machinery, trucks, and industrial equipment.

4. Leistungsmerkmale

4.1 Strength and Load-Bearing Capacity

-

Engineered to support heavy dynamic and static loads.

-

Used in construction, transportation, and industrial manufacturing.

4.2 Corrosion Resistance

-

Galvanized and stainless steel options provide extended service life in harsh environments.

4.3 Rutschfestigkeit

-

Serrated surfaces available for enhanced safety in wet or oily conditions.

4.4 Fire and Heat Resistance

-

Heavy-duty steel grating is non-combustible, making it suitable for high-temperature environments.

5. Applications of Heavy Duty Steel Grating

-

Highways & Bridges: Used for bridge decking, drainage covers, and pedestrian walkways.

-

Airports & Docks: Ideal for loading areas where high strength is required.

-

Industrial Plants: Used in platforms, flooring, stair treads, and walkways.

-

Mining & Offshore Facilities: Corrosion-resistant grating suitable for extreme conditions.

-

Military & Heavy Equipment Areas: Designed to withstand the weight of armored vehicles and machinery.

Hochleistungs-Stahlgitter

Serie :

Proxy-Produkte >Anwendung

Industrielle Laufstege und Plattformen: Bieten sichere Gehflächen in Produktionsanlagen und Raffinerien. Entwässerungsabdeckungen und Rinnenroste: Gewährleisten den ordnungsgemäßen Wasserabfluss im öffentlichen Raum. Brücken und Fahrbahnen: Robuste Roste tragen Fahrzeuglasten. Treppenstufen: Rutschfeste Stufen für Gebäude und Außenbereiche. Sicherheitszäune und -umzäunungen: Stabile und langlebige Absperrungen für Sperrbereiche.

FAQ

Andere verwandte Produkte