Introducción al rendimiento del producto

Rejilla de plástico, también conocida como Rejilla de FRP (plástico reforzado con fibra de vidrio), Es una alternativa moderna a las rejillas metálicas tradicionales. Fabricada con filamentos de fibra de vidrio incrustados en una matriz de resina termoendurecible, la rejilla de plástico ofrece una solución resistente, ligera y resistente a la corrosión para una amplia gama de aplicaciones. Es especialmente popular en entornos donde el metal se corroe rápidamente o requiere mantenimiento frecuente, como plantas químicas, instalaciones de aguas residuales, muelles marítimos y áreas de procesamiento de alimentos.

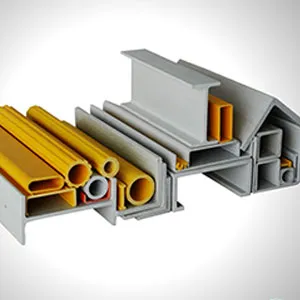

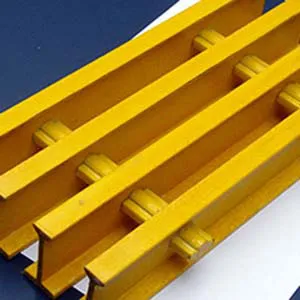

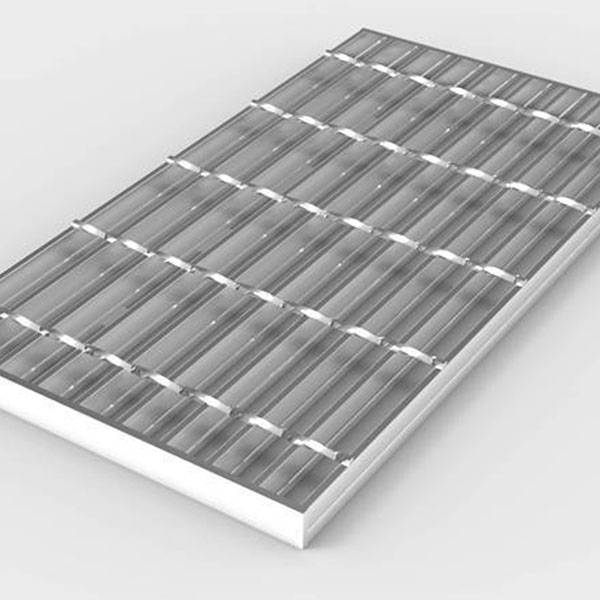

Disponible en ambos moldeado y pultruido Las rejillas de plástico ofrecen una excelente relación resistencia-peso y resisten productos químicos agresivos, exposición a rayos UV, humedad e impactos. La rejilla moldeada se fabrica en una sola pieza para una resistencia multidireccional y es ideal para zonas con tráfico peatonal o donde el drenaje y la resistencia al deslizamiento son prioritarios. La rejilla pultruida, fabricada mediante el estirado de fibras continuas de fibra de vidrio a través de resina y su moldeado en barras, es más resistente en la dirección de carga y adecuada para aplicaciones de alta resistencia.

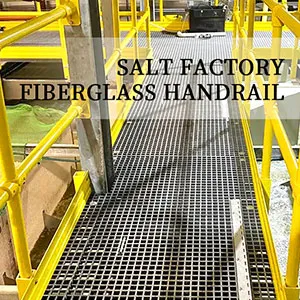

Uno de los beneficios clave de la rejilla de plástico es su no conductor, no magnético, y retardante de fuego propiedades, lo que lo hace ideal para la seguridad eléctrica y zonas industriales de alto riesgo. También ofrece una superficie antideslizante—especialmente cuando se moldean con arena o capas superiores dentadas—lo que mejora la seguridad en el lugar de trabajo.

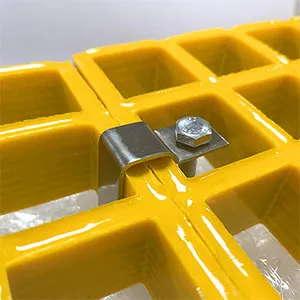

La rejilla de plástico es fácil de cortar, instalar y mantener, y su bajo peso reduce los costos de transporte y manipulación. Su mayor vida útil y sus mínimos requisitos de mantenimiento la convierten en una opción rentable a largo plazo.

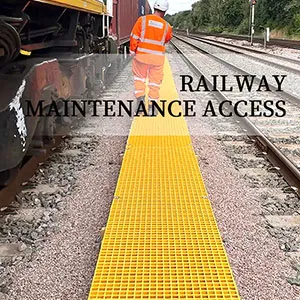

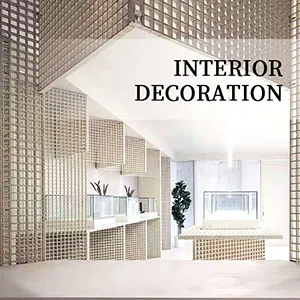

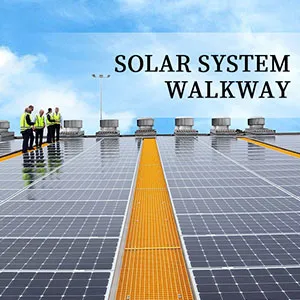

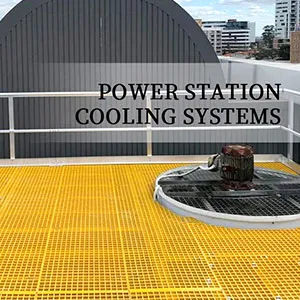

Ya sea que se utilicen para cubrir zanjas, pasarelas, entrepisos, escaleras o pasarelas en azoteas, las rejillas de plástico brindan rendimiento y valor en entornos que desafían los materiales convencionales.

Especificaciones y parámetros técnicos de las rejillas de plástico

| Parámetro | Opciones de especificación |

|---|---|

| Composición del material | Plástico reforzado con fibra de vidrio (FRP) con poliéster, éster de vinilo o resina fenólica |

| Tipo | Rejilla de FRP moldeada, rejilla de FRP pultruida |

| Opciones de superficie | Cóncava (estándar), superficie de grano (antideslizante), cubierta (superficie sólida) |

| Tamaño de malla | 38×38 mm (1,5″ x 1,5″), 50×50 mm (2″ x 2″), Mini malla: 19×19 mm (¾” x ¾”) |

| Altura de la rejilla (espesor) | 25 mm, 30 mm, 38 mm, 50 mm, 60 mm |

| Tamaño del panel | Estándar: 1220×3660 mm (4'x12'), 1000×3000 mm; Tamaños personalizados disponibles |

| Capacidad de carga | Varía según el espesor y la longitud; normalmente entre 500 y 2000 kg/m² (uso ligero a pesado) |

| Área abierta | 60% – 70% para malla estándar; inferior para tipos de malla cubierta o mini |

| Temperatura de funcionamiento | -40 °C a +120 °C continuos; hasta 180 °C para FRP de base fenólica |

| Retardancia del fuego | Disponible (cumple con ASTM E84 Clase 1, UL94 V-0 para resinas seleccionadas) |

| Resistencia a los rayos UV | Inhibidores UV añadidos; adecuado para uso en exteriores. |

| Resistencia a la corrosión | Excelente contra ácidos, álcalis, sales y disolventes. |

| Conductividad eléctrica | No conductor, ideal para entornos eléctricos o de alto voltaje. |

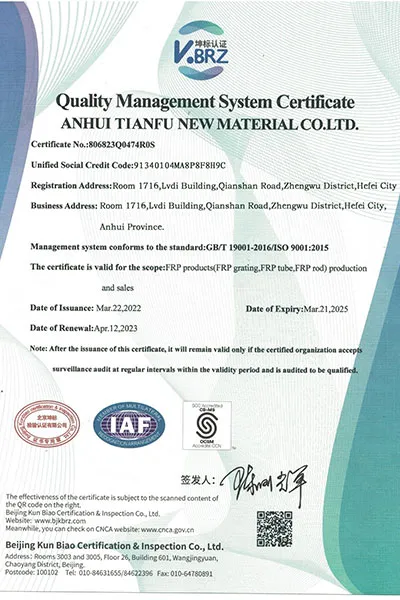

| Certificaciones | ISO 9001, ASTM E84, OSHA, ANSI, BS 4592 (varía según el fabricante y la aplicación) |

¿Por qué elegirnos?

Experiencia en la fabricación de rejillas de PRFV

Con más de 20 años de experiencia, nuestra fábrica se especializa exclusivamente en el diseño, desarrollo y producción de rejillas de FRP (plástico reforzado con fibra de vidrio) de alto rendimiento. Nuestro profundo conocimiento del sector garantiza que cada producto cumpla con los estándares industriales más exigentes.

Tecnología y equipos avanzados

Utilizamos equipos de fabricación de vanguardia y tecnología de moldeo de precisión para producir rejillas con una resistencia superior, resistencia a la corrosión y precisión dimensional. Nuestro compromiso con la innovación significa que su proyecto se beneficia de los últimos avances en tecnología FRP.

Soluciones personalizadas

Desde tamaños de paneles y tipos de resina hasta acabados de superficies y colores, ofrecemos personalización completa para satisfacer sus necesidades de aplicación únicas, ya sean pisos industriales, escalones de escaleras, cubiertas de zanjas o plataformas marinas.

Control de calidad estricto

Cada producto se somete a un riguroso proceso de inspección de calidad, que incluye pruebas de carga, comprobaciones de resistencia al fuego y análisis de resistencia a la corrosión. Nuestro sistema de gestión de calidad con certificación ISO garantiza una excelencia constante en cada lote.

Precios competitivos

Ofrecemos precios directos de fábrica sin comprometer la calidad. Con procesos de producción optimizados y capacidad de fabricación a gran escala, ayudamos a nuestros clientes a lograr ahorros de costos a gran escala.

Entrega confiable y alcance global

Mantenemos un amplio stock de productos estándar y operamos un sistema logístico optimizado, lo que garantiza plazos de entrega rápidos a nivel local e internacional. Hemos atendido con éxito a clientes en más de 15 países.

Productos de gran venta

Escenarios de aplicación

Acerca de la fábrica

Somos un fabricante profesional de rejillas de PRFV con más de 20 años de experiencia. Nuestra fábrica de 26.000 m² cuenta con la certificación ISO9001 y atendemos a clientes en más de 30 países con capacidad OEM/ODM. Ofrecemos soluciones personalizadas y entregas rápidas a nivel mundial.

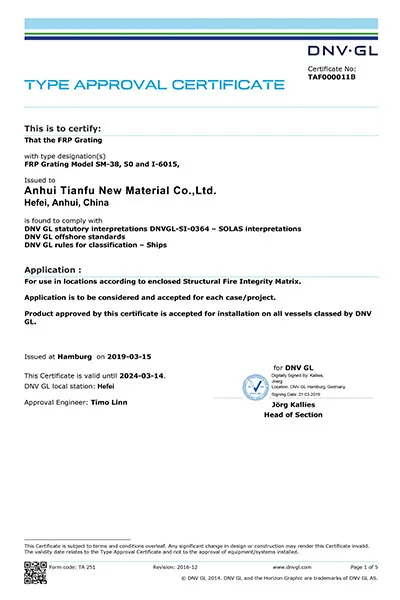

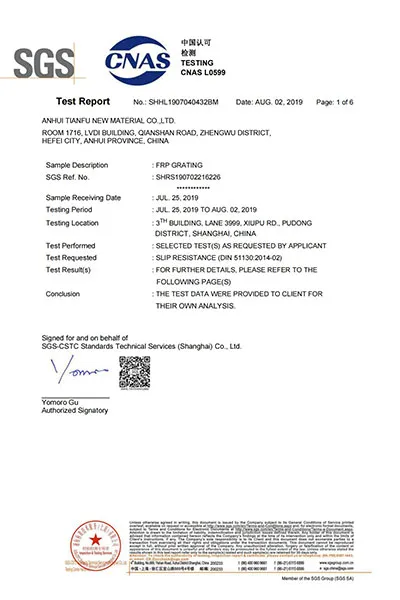

Nuestras rejillas de PRFV se fabrican según las normas ISO 9001 y se someten a pruebas de rendimiento mecánico según las normas ASTM E84 (resistencia al fuego Clase 1) y ASTM D638/D790, además de cumplir con las normas BS 476 y EN 13706. Se ofrecen pruebas independientes a través de SGS y TÜV previa solicitud.

Exhibición

JEC MUNDIAL 2023

MUNDO JEC 2024

CAMX 2025

SHANGHÁI 2025

Certificado

Otros productos

Visita a la fábrica de realidad virtual

Rejilla de plástico

solicitud

Instalaciones industriales, Plantas de tratamiento de aguas residuales, Plataformas marinas y offshore, Procesamiento de alimentos y bebidas, Áreas eléctricas y de servicios públicos, Minería y procesamiento de metales, Infraestructura arquitectónica y pública

Tipo :

Rejilla de FRP moldeada, rejilla de FRP pultruida

Opciones de superficie:

Cóncava (estándar), superficie de grano (antideslizante), cubierta (superficie sólida)

Tamaño de malla:

38×38 mm (1,5"x1,5"), 50×50 mm (2"x2"), Minimalla: 19×19 mm (¾"x¾")

Altura de la rejilla (espesor):

25 mm, 30 mm, 38 mm, 50 mm, 60 mm

Tamaño del panel:

Estándar: 1220 × 3660 mm (4' x 12'), 1000 × 3000 mm; tamaños personalizados disponibles

Preguntas más frecuentes

P:

¿De qué está hecha la rejilla de plástico?

A :

La rejilla de plástico generalmente está hecha de plástico reforzado con fibra de vidrio (FRP), combinando hebras de fibra de vidrio con una resina termoendurecible como poliéster, éster de vinilo o fenólico para lograr resistencia y resistencia química.

P:

¿Cuál es la diferencia entre la rejilla de plástico moldeada y la pultruida?

A :

La rejilla moldeada ofrece resistencia bidireccional y es ideal para uso general con cargas moderadas. La rejilla pultruida es más resistente en una dirección y es más adecuada para cargas pesadas o luces largas.

P:

¿Dónde se utiliza comúnmente la rejilla de plástico?

A :

Las rejillas de plástico se utilizan en plantas químicas, instalaciones de aguas residuales, entornos marinos, áreas de procesamiento de alimentos, plataformas petrolíferas y pasarelas o plataformas donde la resistencia a la corrosión y la seguridad son cruciales.

P:

¿La rejilla de plástico es antideslizante?

A :

Sí, la mayoría de las rejillas de plástico vienen con una superficie cóncava o con gravilla para mejorar la resistencia al deslizamiento, especialmente en entornos húmedos, aceitosos o de mucho tráfico.

P:

¿Puede la rejilla de plástico soportar productos químicos agresivos?

A :

Por supuesto. Las rejillas de plástico tienen una excelente resistencia química, especialmente cuando se fabrican con resinas de éster de vinilo o fenólicas, lo que las hace aptas para entornos corrosivos.

P:

¿La rejilla de plástico es ignífuga?

A :

Sí. Existen formulaciones retardantes de fuego que cumplen con estándares como ASTM E84 Clase 1 y UL94 V-0, dependiendo del tipo de resina utilizada.

P:

¿Es posible cortar o personalizar la rejilla de plástico en el lugar?

A :

Sí. La rejilla de plástico se puede cortar fácilmente con herramientas estándar y se pueden realizar formas, orificios o muescas personalizados en el lugar sin comprometer la integridad estructural.

Otros productos relacionados