Présentation des performances du produit

Plastic floor tiles are an increasingly popular choice for both residential and commercial spaces due to their durability, affordability, and ease of installation. Made primarily from polypropylene (PP), polyvinyl chloride (PVC), ou recycled polymers, these tiles offer a practical and modern alternative to traditional flooring like ceramic, wood, or concrete.

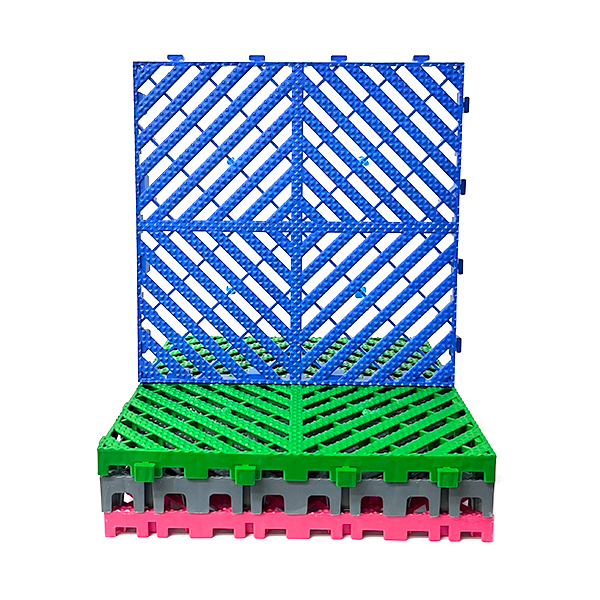

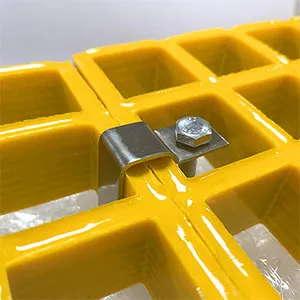

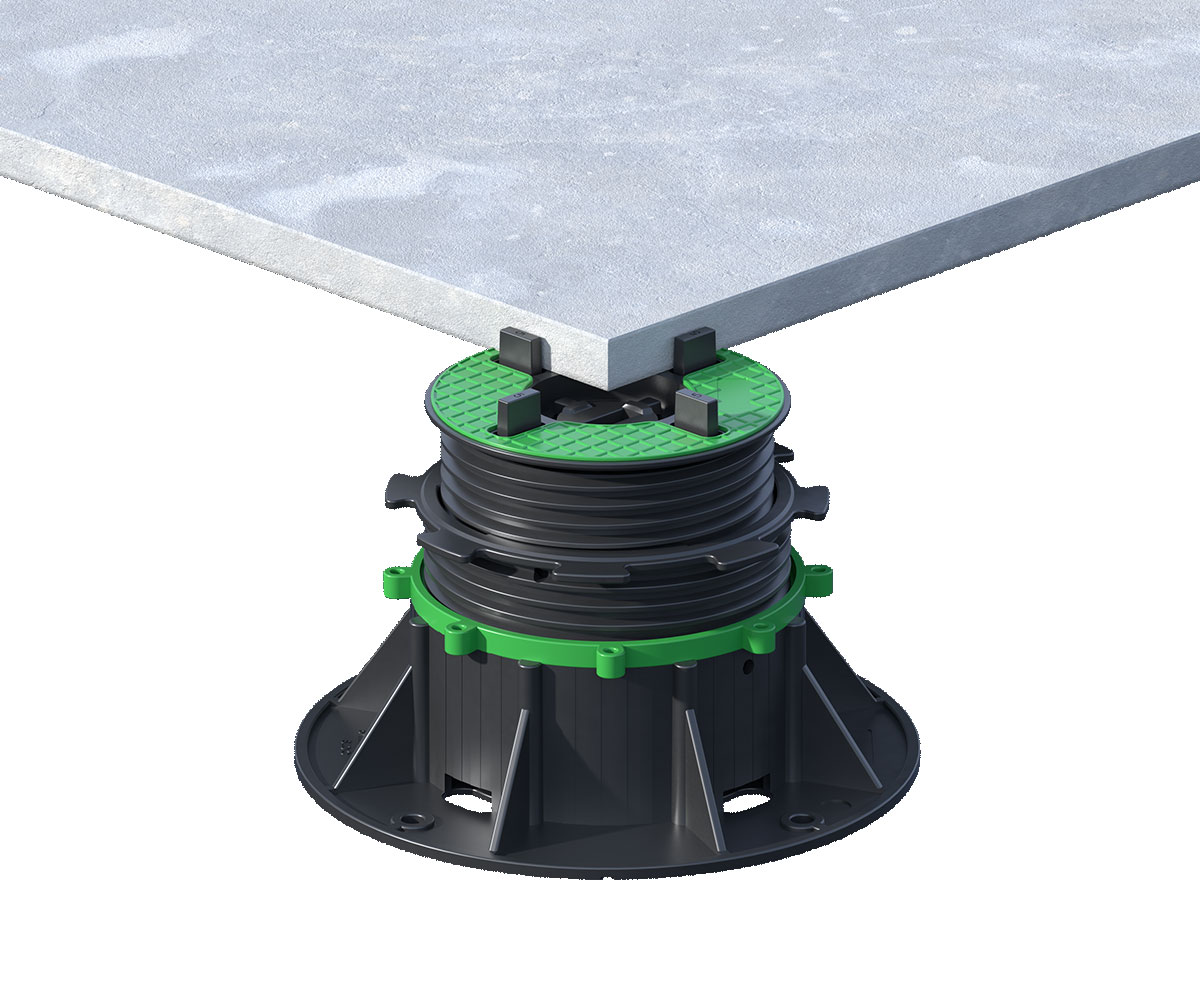

One of the most attractive features of plastic floor tiles is their modular interlocking design, which allows for quick DIY installation without the need for adhesives or special tools. This makes them ideal for temporary or semi-permanent spaces, such as exhibition halls, event stages, rental spaces, et garage floors. Many models are also suitable for outdoor use, thanks to their UV resistance and weatherproof construction.

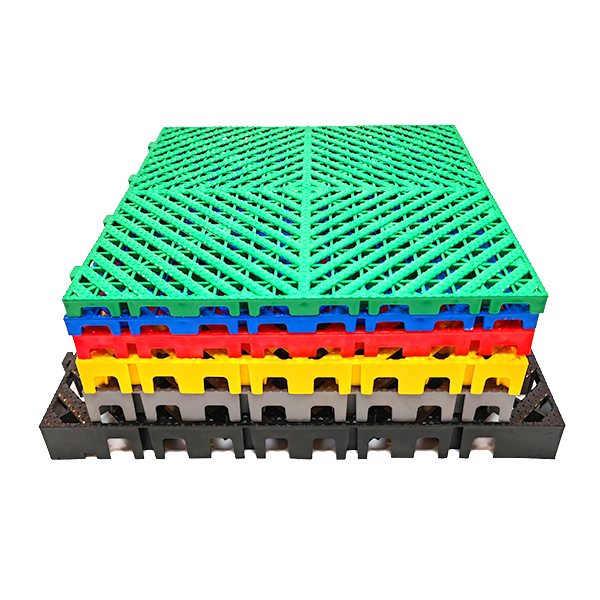

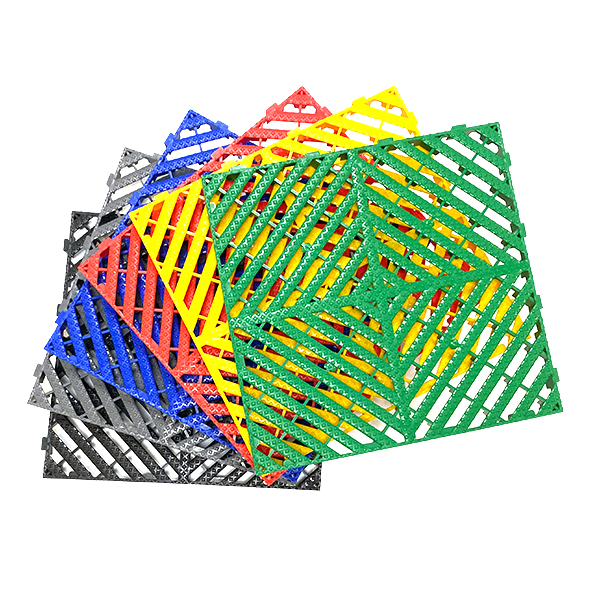

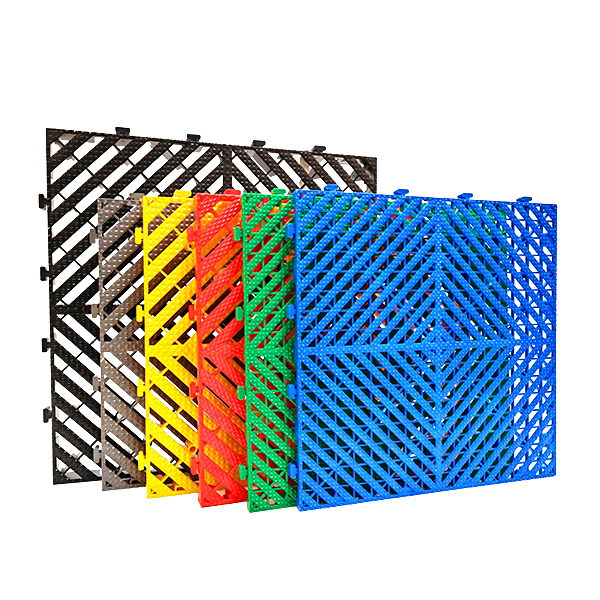

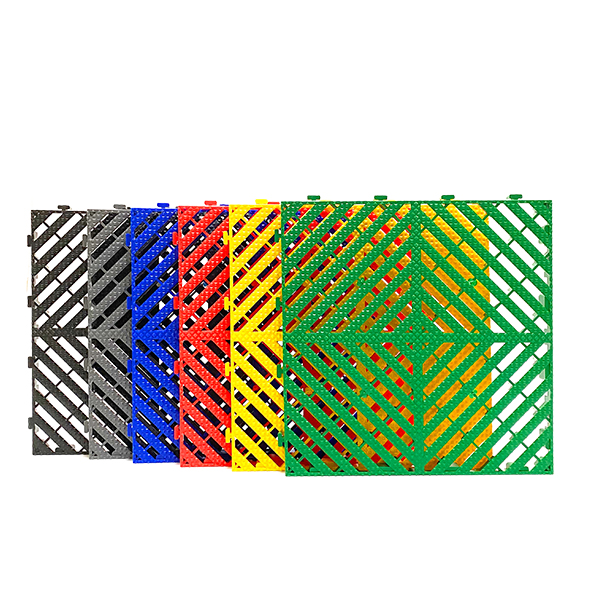

Plastic floor tiles come in a wide range of colors, surface textures, and patterns, y compris wood-look, stone-look, et plain industrial finishes. Some designs offer ventilated or perforated surfaces to allow drainage, making them perfect for wet areas like poolsides, locker rooms, and shower stalls.

In industrial settings, plastic floor tiles are valued for their anti-slip properties, résistance chimique, and ability to support heavy loads. Reinforced tiles can be used in warehouses, workshops, et factories, where performance and safety are paramount.

These tiles are also low-maintenance—most only require occasional cleaning with water and mild detergent. Should any damage occur, individual tiles can be easily replaced without disturbing the entire floor.

From playrooms and patios à gyms and garages, plastic floor tiles offer a cost-effective, long-lasting solution with plenty of visual appeal and functional benefits. Their versatility, resilience, et eco-friendly options make them a smart choice for modern flooring needs.

Plastic Floor Tile Specifications & Technical Parameters

| Paramètre | Options de spécification |

|---|---|

| Matériel | Polypropylene (PP), Polyvinyl Chloride (PVC), Recycled Plastics |

| Tile Type | Interlocking, Glue-down, Loose-lay |

| Tile Size | 300×300 mm, 400×400 mm, 500×500 mm, 610×610 mm (12″x12″, 20″x20″, 24″x24″) |

| Épaisseur | 4 mm – 20 mm (depends on load capacity and usage type) |

| Finition de surface | Smooth, Textured, Wood-grain, Stone-look, Perforated, Grit-coated (anti-slip) |

| Options de couleur | Black, Gray, Blue, Red, Green, Custom RAL Colors Available |

| Capacité de chargement | 250 kg to 5,000 kg/m² (standard to heavy-duty industrial use) |

| Résistance au glissement | R9 – R13 rated (depending on surface design and coating) |

| Résistance au feu | Available (meets EN 13501-1, UL 94 HB or V-0 depending on resin type) |

| Résistance chimique | Resistant to oils, greases, acids, alkalis, and cleaning agents |

| Water Resistance | 100% waterproof; perforated options allow for drainage |

| Résistance aux UV | Optional UV-stabilized version available for outdoor applications |

| Méthode d'installation | Interlocking (snap-fit), adhesive bonding, or loose-laid depending on application |

| Température de fonctionnement | -20°C to +70°C standard; up to +100°C for heat-resistant versions |

| Entretien | Easy to clean with mild detergent and water; individual tiles can be replaced if damaged |

| Certifications | ISO 9001, REACH, RoHS, CE, ASTM (varies by manufacturer and region) |

Pourquoi nous choisir ?

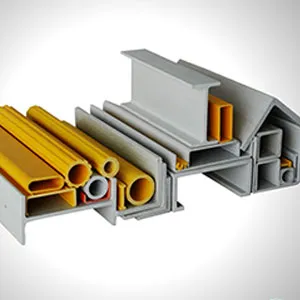

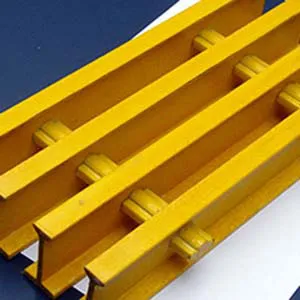

Expertise dans la fabrication de caillebotis en PRV

Forte de plus de 20 ans d'expérience, notre usine se spécialise exclusivement dans la conception, le développement et la production de caillebotis haute performance en PRV (plastique renforcé de fibres de verre). Notre expertise approfondie du secteur garantit que chaque produit répond aux normes industrielles les plus exigeantes.

Technologies et équipements de pointe

Nous utilisons des équipements de fabrication de pointe et une technologie de moulage de précision pour produire des caillebotis d'une résistance, d'une résistance à la corrosion et d'une précision dimensionnelle supérieures. Notre engagement envers l'innovation garantit à votre projet l'accès aux dernières avancées en matière de technologie des matériaux composites à fibres de verre (FRP).

Solutions personnalisées

Des dimensions des panneaux aux types de résine, en passant par les finitions de surface et les couleurs, nous offrons une personnalisation complète pour répondre à vos besoins spécifiques, qu'il s'agisse de revêtements de sol industriels, de marches d'escalier, de couvercles de tranchées ou de plateformes marines.

Contrôle de qualité rigoureux

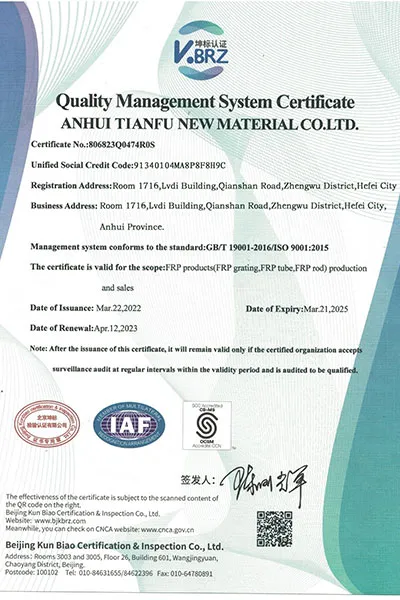

Chaque produit est soumis à un contrôle qualité rigoureux, comprenant des tests de charge, des contrôles de résistance au feu et une analyse de la résistance à la corrosion. Notre système de gestion de la qualité certifié ISO garantit une excellence constante pour chaque lot.

Prix compétitifs

Nous proposons des prix directs d'usine sans compromis sur la qualité. Grâce à des processus de production optimisés et à nos capacités de production en grande série, nous aidons nos clients à réaliser des économies d'échelle.

Livraison fiable et portée mondiale

Nous disposons d'un stock important de produits standards et d'un système logistique optimisé, garantissant des délais de livraison rapides à l'échelle locale et internationale. Nous avons servi avec succès des clients dans plus de 15 pays.

Produits les plus vendus

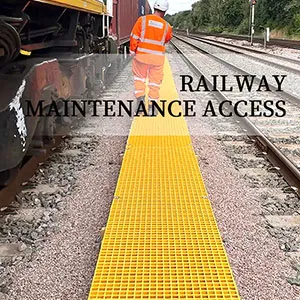

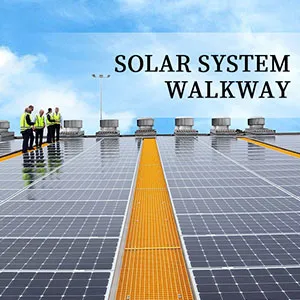

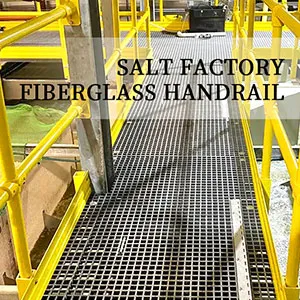

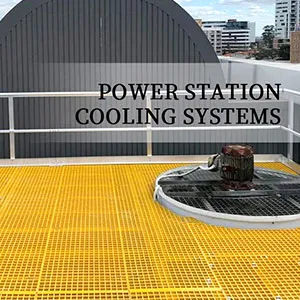

Scénarios d'application

À propos de l'usine

Nous sommes un fabricant professionnel de caillebotis en PRV (polyester renforcé de fibres de verre) avec plus de 20 ans d'expérience. Notre usine de 26 000 m² est certifiée ISO 9001 et nous fournissons des services OEM/ODM à des clients dans plus de 30 pays. Nous proposons des solutions sur mesure et une livraison rapide dans le monde entier.

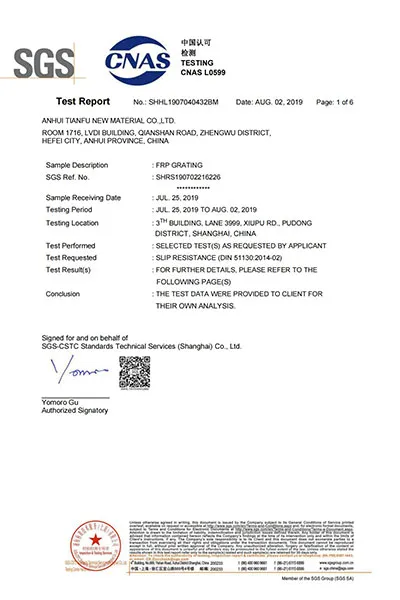

Nos caillebotis en PRV sont fabriqués conformément à la norme ISO 9001 et testés selon les normes ASTM E84 (classe de résistance au feu 1), ASTM D638/D790 (performances mécaniques) et sont conformes aux normes BS 476 et EN 13706. Des tests réalisés par des organismes tiers (SGS et TÜV) sont disponibles sur demande.

Exposition

JEC WORLD 2023

JEC MONDE 2024

CAMX 2025

SHANGHAI 2025

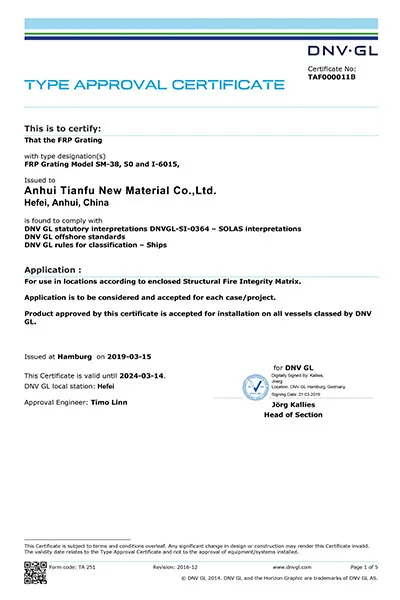

Certificat

Autres produits

Visite de l'usine VR

Dalles de sol en plastique

Série :

Principaux produits >application

Garages & Workshops,Commercial & Retail Spaces,Gyms & Sports Facilities,Playgrounds & Kids’ Areas,Poolside & Locker Rooms,Events & Temporary Flooring,Industrial & Warehouse Settings

Tile Type :

Interlocking, Glue-down, Loose-lay

Tile Size :

300×300 mm, 400×400 mm, 500×500 mm, 610×610 mm (12"x12", 20"x20", 24"x24")

Épaisseur :

4 mm – 20 mm (depends on load capacity and usage type)

Hauteur (épaisseur) de la grille :

25 mm, 30 mm, 38 mm, 50 mm, 60 mm

Finition de surface :

Smooth, Textured, Wood-grain, Stone-look, Perforated, Grit-coated (anti-slip)

Color Options :

Black, Gray, Blue, Red, Green, Custom RAL Colors Available

Load Capacity :

250 kg to 5,000 kg/m² (standard to heavy-duty industrial use)

Slip Resistance :

R9 – R13 rated (depending on surface design and coating)

FAQ

Q :

What materials are plastic floor tiles made of?

UN :

Most plastic floor tiles are made from polypropylene (PP) or polyvinyl chloride (PVC). Some models also use recycled plastics, offering eco-friendly options.

Q :

Are plastic floor tiles suitable for outdoor use?

UN :

Yes. Many plastic tiles are designed for outdoor environments and feature UV resistance, water drainage holes, and anti-slip textures, making them ideal for patios, balconies, pool decks, or garden walkways.

Q :

How are plastic floor tiles installed?

UN :

Plastic floor tiles often use an interlocking system that snaps together without the need for glue or nails. Some types are glue-down or loose-lay, depending on the application.

Q :

Can plastic tiles handle heavy loads?

UN :

Yes. Heavy-duty plastic tiles can support cars, machinery, or equipment—ideal for garages, workshops, and industrial spaces. Always check the load capacity rating of the specific tile model.

Q :

Are plastic tiles safe in wet areas?

UN :

Absolutely. Most plastic tiles are 100% waterproof, and some feature textured or grit-coated surfaces for enhanced slip resistance in wet environments like bathrooms or locker rooms.

Q :

How do you clean and maintain plastic floor tiles?

UN :

Plastic tiles are low-maintenance. They can be cleaned using water, mild detergent, or a mop. Damaged tiles can be replaced individually without removing the entire floor.

Q :

Are plastic tiles eco-friendly?

UN :

Tianfu offer recyclable or recycled-content plastic tiles, making them a more sustainable choice compared to traditional flooring materials like vinyl sheet or ceramic.

Autres produits connexes