Introduzione alle prestazioni del prodotto

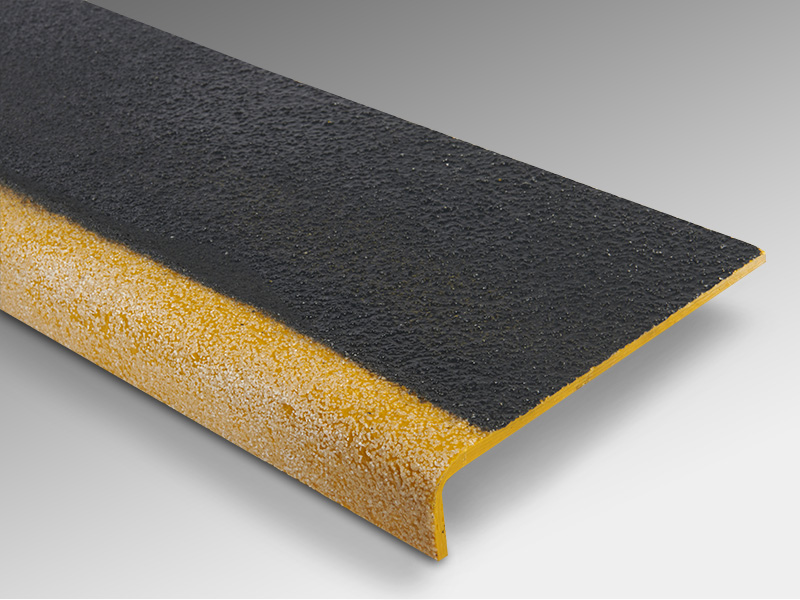

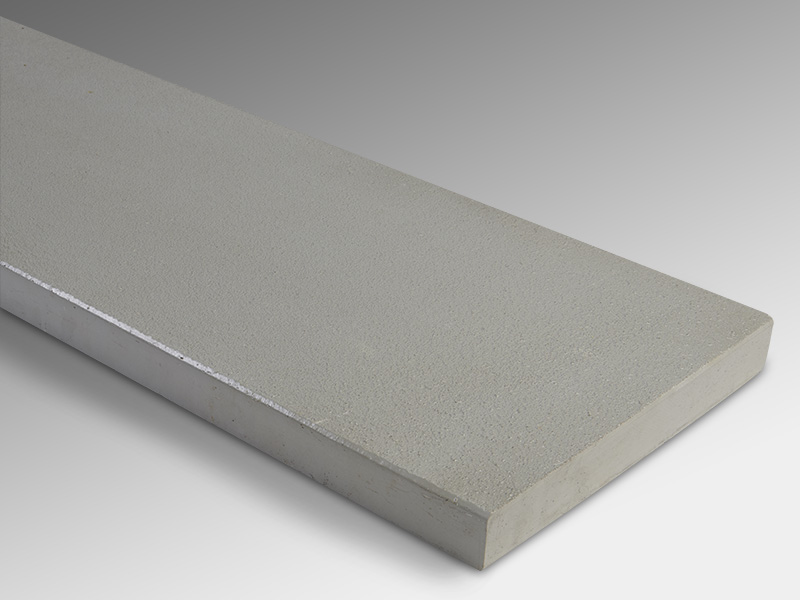

I coprigradini in FRP (plastica rinforzata con fibra di vetro) sono soluzioni di sicurezza ad alte prestazioni, progettate per garantire resistenza allo scivolamento, rinforzo strutturale e maggiore durata alle scale esistenti. Questi coprigradini vengono solitamente installati su scale usurate o scivolose in cemento, legno o metallo, rendendoli ideali sia per progetti di ristrutturazione che di nuova costruzione in vari ambienti industriali, commerciali e persino pubblici.

Realizzati utilizzando una combinazione di rinforzi in fibra di vetro e sistemi di resine termoindurenti, come poliestere isoftalico, vinilestere o resina fenolica, i coprigradini in FRP sono progettati per resistere a condizioni ambientali difficili, traffico pedonale intenso ed esposizione a sostanze chimiche. Il risultato è un prodotto di sicurezza per scale durevole e resistente alla corrosione, che riduce significativamente il rischio di scivolamenti e cadute.

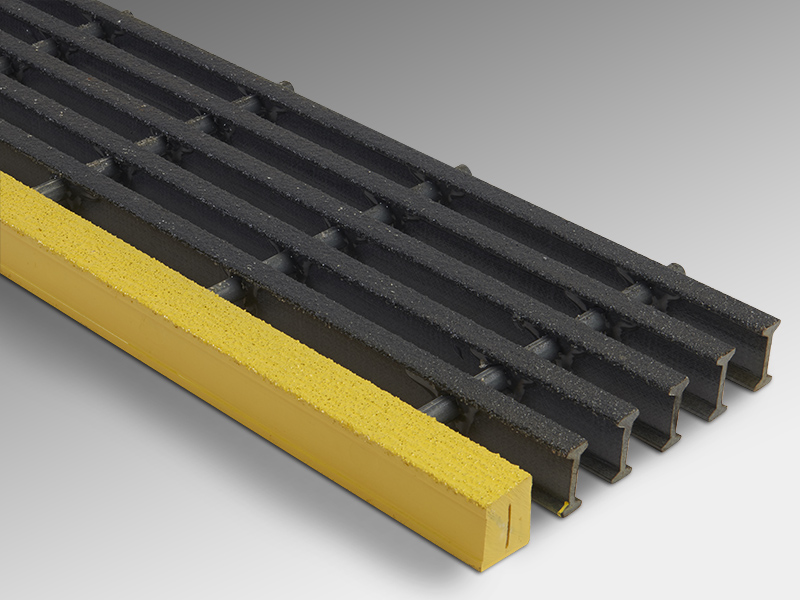

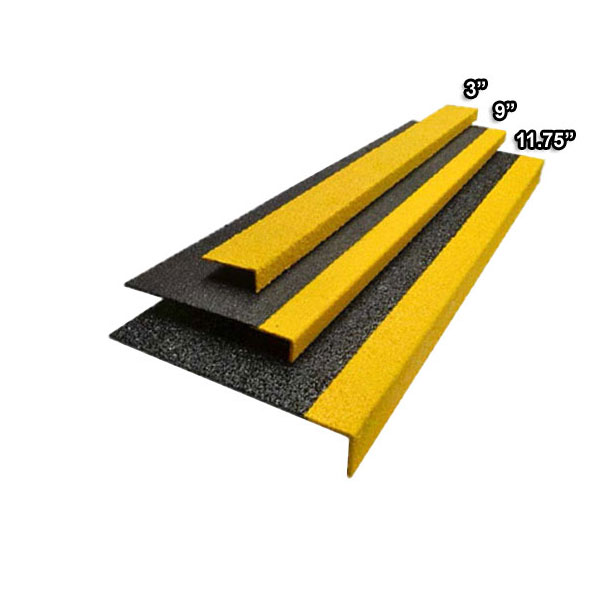

Una delle caratteristiche principali dei coprigradini in FRP è la loro superficie antiscivolo. La maggior parte dei coprigradini è dotata di una superficie in graniglia altamente abrasiva, realizzata con particelle di ossido di alluminio fuso o quarzo siliceo, fissate in modo permanente allo strato superiore. Questa graniglia offre una trazione eccezionale in condizioni di bagnato, olio o ghiaccio ed è conforme agli standard di sicurezza OSHA e ADA. I coprigradini sono disponibili anche con bordi a contrasto ad alta visibilità, solitamente in giallo o altri colori vivaci, che migliorano la visibilità e favoriscono l'identificazione sicura dei gradini.

I coprigradini in FRP sono leggeri ma estremamente resistenti. Sono facili da installare con elementi di fissaggio meccanici o adesivi e richiedono una manutenzione minima per tutta la loro durata. Le loro proprietà non conduttive e antiscintilla li rendono adatti anche all'uso in impianti elettrici e in ambienti esplosivi. Inoltre, molte versioni sono ignifughe e resistenti ai raggi UV, il che li rende un'opzione affidabile per applicazioni sia interne che esterne.

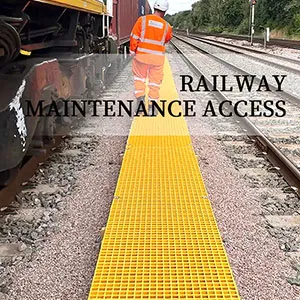

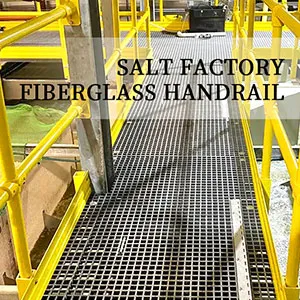

Le applicazioni tipiche delle coperture per gradini in FRP includono stabilimenti di produzione, impianti di lavorazione alimentare, piattaforme petrolifere e del gas, banchine marittime, terminal di trasporto, scuole, ospedali, magazzini e parcheggi. In luoghi in cui le scale sono frequentemente esposte a umidità, grasso o fuoriuscite di sostanze chimiche, queste coperture offrono un miglioramento della sicurezza altamente efficace e duraturo.

Specifiche tecniche Le dimensioni variano a seconda del produttore, ma i coprigradini standard in FRP sono disponibili in spessori da 3 mm a 5 mm (da 1/8" a 3/16") e in genere hanno larghezze standard da 70 mm a 300 mm (da 2,75" a 12") con profondità fino a 1200 mm (4 piedi). Sono disponibili anche misure personalizzate per adattarsi a scale non standard. Il bordo del gradino è spesso stampato o applicato come parte integrante del coprigradino per resistere allo sfaldamento o al distacco nel tempo.

Inoltre, i rivestimenti per gradini in FRP contribuiscono al raggiungimento degli obiettivi di sostenibilità, poiché spesso durano più a lungo dei materiali tradizionali, riducendo la necessità di sostituzioni frequenti. La loro installazione riduce al minimo i tempi di fermo e migliora la sicurezza fin dall'inizio, rendendoli una soluzione conveniente per le strutture che mirano a soddisfare le normative in materia di salute e sicurezza con il minimo disagio.

Specifiche e parametri tecnici del rivestimento del gradino della scala in FRP

1. Specifiche generali

| Parametro | Specifica |

|---|---|

| Nome del prodotto | Coprigradino in FRP |

| Materiale | Plastica rinforzata con fibra di vetro (FRP) |

| Tipi di resina | Poliestere isoftalico, vinilestere, fenolico (su richiesta) |

| Finitura superficiale | Superficie antiscivolo in graniglia (ossido di alluminio o quarzo) |

| Nasi | Alta visibilità (giallo, nero, bianco, fosforescente, ecc.) |

| Resistenza al fuoco (ASTM E84) | Classe 1 (indice di propagazione della fiamma ≤ 25) |

| Resistenza ai raggi UV | Disponibile con inibitori UV |

| Conduttività elettrica | Non conduttivo |

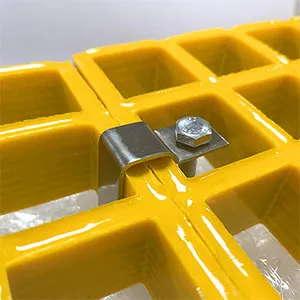

| Installazione | Incollaggio adesivo o elementi di fissaggio meccanici |

| Resistenza alla temperatura | da -40°C a +120°C (standard); più alta con resina speciale |

| Certificazioni | OSHA, ADA, ASTM, ANSI, ISO a seconda della variante |

2. Specifiche dimensionali:

| Parametro | Valore/intervallo tipico |

|---|---|

| Spessore | 3 mm (1/8″), 4 mm (5/32″), 5 mm (3/16″) |

| Larghezza (profondità del battistrada) | Da 70 mm a 300 mm (da 2,75″ a 12″) |

| Lunghezza (larghezza del battistrada) | Fino a 1200 mm (48″); dimensioni personalizzate disponibili |

| Larghezza dei bordi | Da 25 mm a 50 mm (da 1″ a 2″) |

| Opzioni colore | Standard: Giallo/Nero; Colori RAL personalizzati disponibili |

| Copertura della superficie | Copertura completa del battistrada o solo del bordo del naso |

| Area aperta | 0% (profilo solido per la massima trazione e copertura) |

3. Proprietà meccaniche e fisiche (tipiche):

| Proprietà | Unità | Intervallo di valori |

|---|---|---|

| Resistenza alla trazione | MPa | ≥ 100 |

| Resistenza alla flessione | MPa | 150 – 250 |

| Modulo di flessione | GPa | 6 – 12 |

| Resistenza all'impatto (Izod) | kJ/m² | ≥ 90 |

| Resistenza alla compressione | MPa | 200 – 350 |

| Densità | g/cm³ | 1,6 – 1,9 |

| Assorbimento d'acqua (24 ore) | % in peso | < 0,5% |

| Resistenza allo scivolamento (coefficiente) | Asciutto: ≥ 0,8; Bagnato: ≥ 0,6 (ASTM D2047 o BS 7976) |

Perché sceglierci

Competenza nella produzione di grigliati in FRP

Con oltre 20 anni di esperienza, il nostro stabilimento è specializzato esclusivamente nella progettazione, sviluppo e produzione di grigliati in FRP (plastica rinforzata con fibra di vetro) ad alte prestazioni. La nostra profonda conoscenza del settore garantisce che ogni prodotto soddisfi i più rigorosi standard industriali.

Tecnologia e attrezzature avanzate

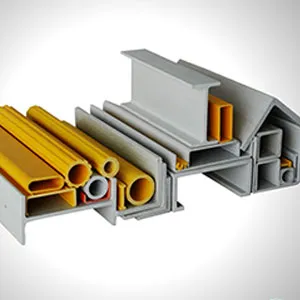

Utilizziamo macchinari di produzione all'avanguardia e tecnologie di stampaggio di precisione per realizzare grigliati con resistenza, resistenza alla corrosione e precisione dimensionale superiori. Il nostro impegno per l'innovazione significa che il vostro progetto beneficia dei più recenti progressi nella tecnologia FRP.

Soluzioni personalizzate

Dalle dimensioni dei pannelli e dai tipi di resina alle finiture e ai colori delle superfici, offriamo una personalizzazione completa per soddisfare le vostre specifiche esigenze applicative, che si tratti di pavimenti industriali, gradini di scale, coperture di trincee o piattaforme marine.

Controllo di qualità rigoroso

Ogni prodotto viene sottoposto a un rigoroso processo di controllo qualità, che include prove di carico, controlli di ignifugazione e analisi di resistenza alla corrosione. Il nostro sistema di gestione della qualità certificato ISO garantisce un'eccellenza costante in ogni lotto.

Prezzi competitivi

Offriamo prezzi di fabbrica diretti senza compromettere la qualità. Grazie a processi produttivi ottimizzati e capacità di produzione in serie, aiutiamo i nostri clienti a ottenere risparmi sui costi su larga scala.

Consegna affidabile e portata globale

Disponiamo di un ampio stock di prodotti standard e gestiamo un sistema logistico efficiente, garantendo tempi di consegna rapidi a livello locale e internazionale. Abbiamo servito con successo clienti in oltre 15 paesi.

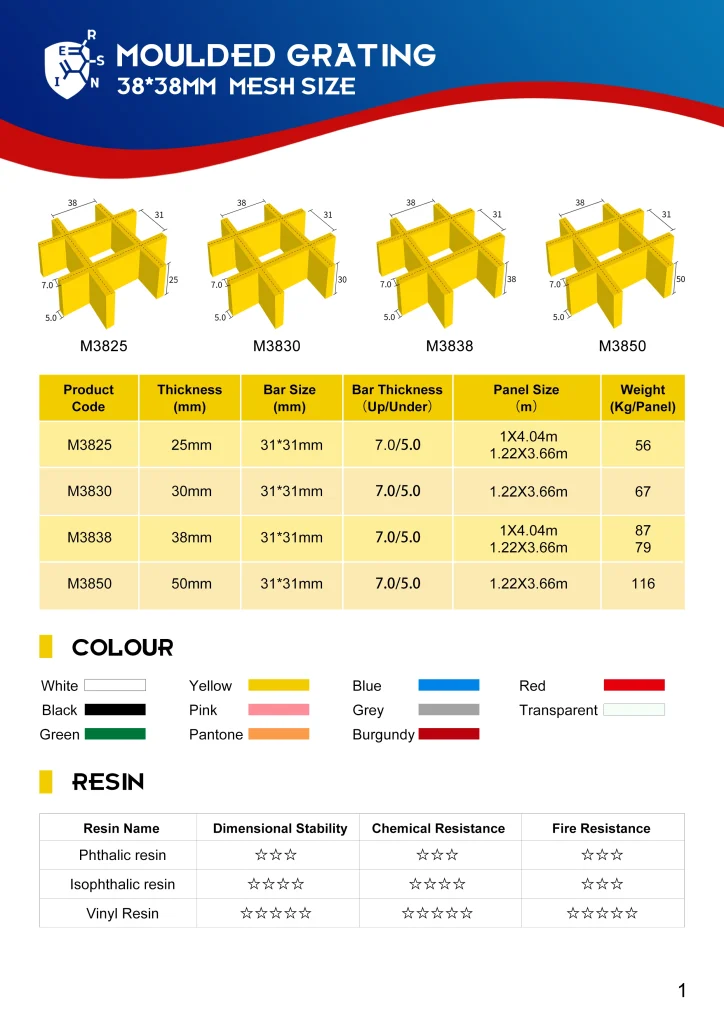

Prodotti più venduti

| Dimensioni standard dei pannelli | 1220 mm × 3660 mm (4 piedi × 12 piedi) 1220 mm × 4000 mm (4 piedi × 13,1 piedi) 915 mm × 3050 mm (3 piedi × 10 piedi) 1000 mm × 3000 mm (personalizzabile) (Altre dimensioni possono essere personalizzate in base alle esigenze del progetto) |

| Opzioni di spessore | 25 mm (1 pollice) 30 mm (1,2 pollici) 38 mm (1,5 pollici) — il più comune 50 mm (2 pollici) |

| Dimensione della maglia (dimensione dell'apertura) | 38 mm × 38 mm (1,5 pollici × 1,5 pollici) — Standard 40 millimetri × 40 millimetri 19 mm × 19 mm (mini-maglia per impedire il passaggio di piccoli oggetti) |

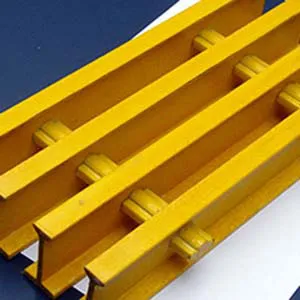

| Larghezza e spaziatura della barra di carico (per grigliati pultrusi) | Larghezza della barra di carico: in genere 25 mm, 38 mm, 50 mm Distanza tra le barre di carico: 25 mm, 40 mm, 50 mm da centro a centro |

| Opzioni di superficie | Superficie granulata (antiscivolo) Superficie liscia Superficie coperta (piano superiore pieno) |

| Colori disponibili | Giallo (il più comune) Verde Grigio Rosso Colori personalizzati su richiesta |

| Tipi comuni di resina | Poliestere isoftalico (resistenza alla corrosione standard) Vinilestere (elevata resistenza chimica) Fenolico (applicazioni resistenti al fuoco) |

Informazioni sulla fabbrica

Anhui Tianfu New Material Co., Ltd è un produttore professionale leader specializzato in Grigliato stampato in FRP Produzione. Con oltre 20 anni di esperienza nel settore dei materiali compositi, ci dedichiamo alla fornitura di soluzioni in plastica rinforzata con fibra di vetro (FRP) di alta qualità per un'ampia gamma di applicazioni industriali e commerciali. Il nostro moderno stabilimento è dotato di linee di produzione avanzate e copre un'area di oltre 26.000 metri quadrati. Offriamo una gamma completa di grigliati stampati in FRP caratterizzati da resistenza superiore, resistenza chimica, ignifugazione e prestazioni antiscivolo. In Tianfu New Material, diamo priorità all'innovazione, al rigoroso controllo qualità e alla soddisfazione del cliente. I nostri prodotti sono certificati secondo gli standard internazionali ed esportati in oltre 30 paesi in tutto il mondo, servendo settori come impianti chimici, impianti di trattamento delle acque reflue, piattaforme offshore e passerelle. Che abbiate bisogno di dimensioni standard o soluzioni personalizzate, Tianfu è il vostro partner affidabile per i grigliati stampati in FRP.

Scenari applicativi

Informazioni sulla fabbrica

Siamo un produttore professionale di grigliati in FRP con oltre 20 anni di esperienza. Il nostro stabilimento di 26.000 m² è certificato ISO9001 e serve clienti in oltre 30 paesi con capacità OEM/ODM. Offriamo soluzioni personalizzate e consegne rapide in tutto il mondo.

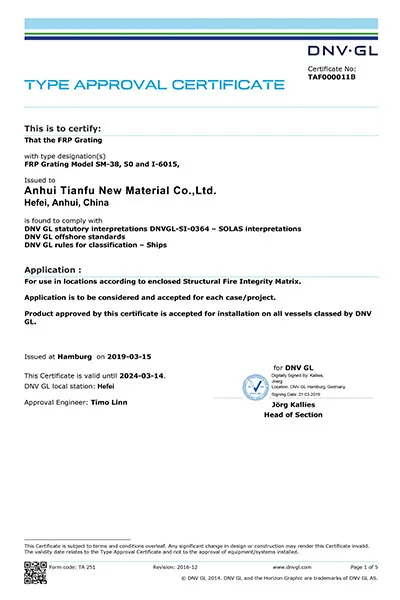

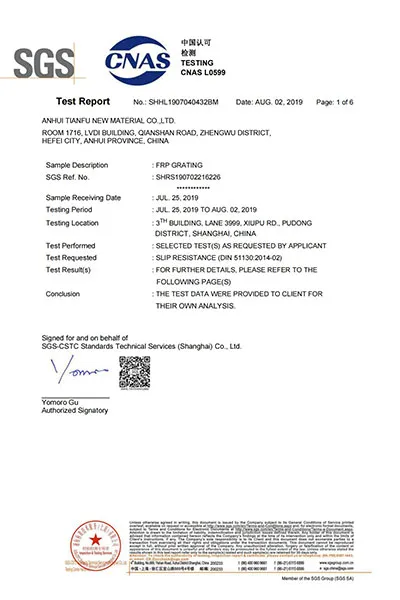

I nostri grigliati in FRP sono realizzati in conformità con gli standard ISO 9001 e testati secondo ASTM E84 (classe di resistenza al fuoco 1), ASTM D638/D790 per le prestazioni meccaniche e sono conformi agli standard BS 476 ed EN 13706. Su richiesta, sono disponibili test di terze parti tramite SGS e TUV.

Esposizione

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

Certificato

Grigliato stampato in FRP (scheda tecnica)

Altri prodotti

Tour della fabbrica VR

Coprigradino in FRP

applicazione

Pavimentazioni industriali, piattaforme marine e offshore, impianti di trattamento delle acque reflue, industria alimentare e delle bevande, infrastrutture di trasporto, cantieri edili, sale batterie e sottostazioni elettriche, spazi pubblici e commerciali, parchi acquatici e piscine, sistemi HVAC e sui tetti

Dimensione della maglia:

38x38 millimetri (1,5

Spessore (Altezza):

25 mm / 30 mm / 38 mm / 50 mm

Dimensioni del pannello:

1220x3660 mm / 1000x4000 mm / Personalizzato

Area aperta:

60% – 70% (a seconda della dimensione della maglia)

Opzioni di superficie:

Superficie liscia / concava / ruvida / coperta

Colore :

Grigio, Giallo, Verde, Rosso, Personalizzato

FAQ

Q :

Cos'è la griglia in fibra di vetro trasparente?

UN :

Il reticolo in fibra di vetro trasparente è un tipo di reticolo in FRP realizzato con resine trasparenti o semitrasparenti. Permette il passaggio della luce, garantendo al contempo la robustezza, la resistenza alla corrosione e la durevolezza dei tradizionali reticoli in fibra di vetro.

Q :

Quali sono le principali applicazioni delle griglie in fibra di vetro trasparenti?

UN :

È ideale per progetti architettonici, passerelle, piattaforme sui tetti, terrazze solarium, soppalchi e aree che richiedono luce naturale. Viene utilizzato anche in ambienti in cui l'estetica e la diffusione della luce sono importanti, come piscine, resort e infrastrutture pubbliche.

Q :

La griglia in fibra di vetro trasparente garantisce una resistenza sufficiente?

UN :

Sì. Le griglie in fibra di vetro trasparente mantengono lo stesso rapporto resistenza/peso delle griglie in FRP tradizionali, in grado di supportare il traffico pedonale, carichi di veicoli leggeri e varie applicazioni industriali, a seconda dello spessore e della spaziatura dei supporti.

Q :

La griglia in fibra di vetro trasparente è resistente ai raggi UV?

UN :

Sì. La maggior parte delle griglie in fibra di vetro trasparenti è realizzata con resine resistenti ai raggi UV, il che garantisce che non si degraderanno né perderanno trasparenza se esposte alla luce solare, rendendole adatte ad applicazioni esterne.

Q :

La griglia in fibra di vetro trasparente è antiscivolo?

UN :

Sì, le griglie in fibra di vetro trasparente possono essere realizzate con una superficie antiscivolo, ad esempio con finitura granulata o testurizzata, per garantire un appoggio sicuro anche in condizioni di bagnato o di olio.

Q :

La griglia in fibra di vetro trasparente è resistente ai raggi UV?

UN :

Sì. La maggior parte delle griglie in fibra di vetro trasparenti è realizzata con resine resistenti ai raggi UV, il che garantisce che non si degraderanno né perderanno trasparenza se esposte alla luce solare, rendendole adatte ad applicazioni esterne.

Q :

Le griglie in fibra di vetro trasparenti possono essere utilizzate in ambienti corrosivi?

UN :

Sì. Come altri prodotti in grigliato di fibra di vetro, il grigliato trasparente in FRP è resistente alla corrosione, il che lo rende ideale per ambienti esposti a sostanze chimiche, acqua salata o condizioni industriali difficili.

Q :

Le griglie in fibra di vetro trasparente sono resistenti al fuoco?

UN :

Sì, le griglie in fibra di vetro trasparenti possono essere prodotte utilizzando resine ignifughe, conformi agli standard di sicurezza antincendio quali ASTM E84 per la propagazione delle fiamme e lo sviluppo di fumo.

Altri prodotti correlati