Introduzione alle prestazioni del prodotto

In the demanding environment of chemical processing facilities, flooring systems must meet rigorous standards in terms of durability, safety, chemical resistance, and ease of maintenance. Traditional materials such as steel and aluminum often fall short in highly corrosive settings. Grata in fibra di vetro, also known as FRP (Fiberglass Reinforced Plastic) grating, has emerged as the optimal solution for industrial flooring in chemical plants due to its exceptional performance and cost-effectiveness over time.

Resistenza alla corrosione superiore

One of the primary reasons fiberglass grating is widely used in chemical plants is its outstanding resistance to corrosive chemicals, acids, alkalis, and solvents. Unlike metal grating, which can corrode, rust, or deteriorate quickly when exposed to aggressive substances, FRP grating is engineered to withstand harsh chemical environments. Depending on the resin used — such as vinyl ester, isophthalic, or phenolic resin — fiberglass grating can provide tailored protection against specific chemical exposures. This makes it suitable for use in areas such as mixing stations, tank farms, acid recovery zones, and waste treatment systems.

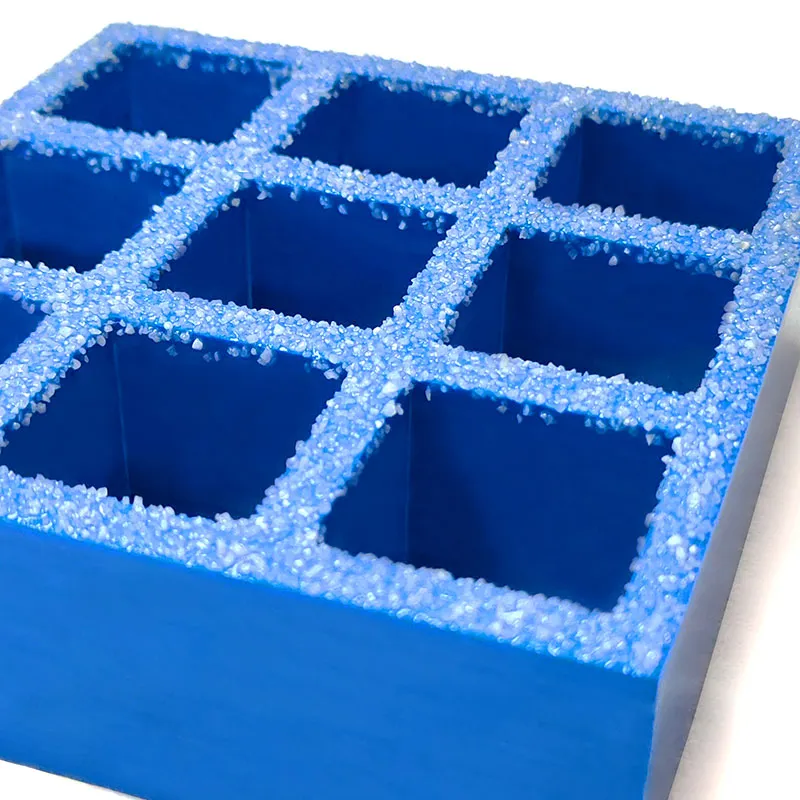

Enhanced Safety and Anti-Slip Performance

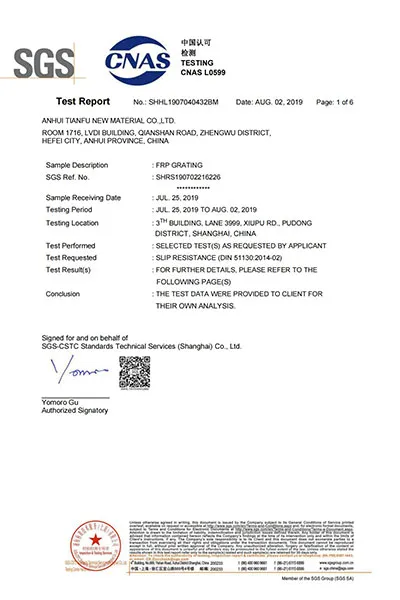

Safety is a top priority in any industrial facility. Fiberglass grating features anti-slip surfaces such as gritted or concave finishes, which provide excellent traction even when wet or contaminated with chemical residues. This significantly reduces the risk of slips and falls, protecting workers in areas where spills and splashes are common. Furthermore, FRP grating is non-conductive and spark-resistant, adding another layer of safety in electrical and flammable chemical processing zones.

Strength and Load-Bearing Capacity

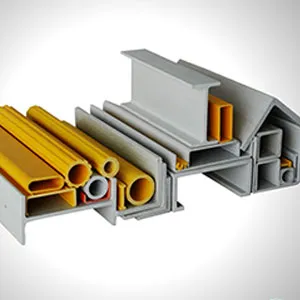

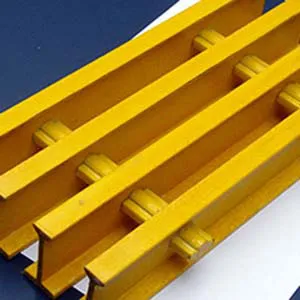

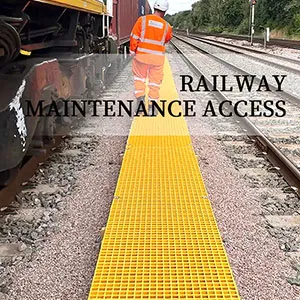

Despite being lightweight, fiberglass grating offers impressive load-bearing capabilities. It can be used for flooring, walkways, stair treads, trench covers, and platforms in areas with moderate to heavy foot traffic or equipment loads. Pultruded FRP grating, in particular, is ideal for applications requiring high mechanical strength over long spans.

Low Maintenance and Long Service Life

In chemical plants where downtime is costly, minimizing maintenance is critical. Fiberglass grating is virtually maintenance-free. It does not require painting, coating, or galvanizing. Its non-corrosive nature prevents degradation, and its non-porous surface resists staining and microbial growth. With proper installation, FRP grating can last 20–25 years or more, reducing the total cost of ownership.

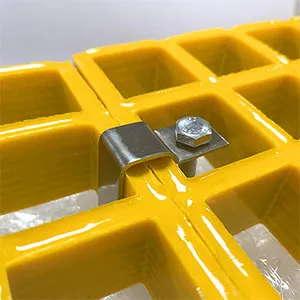

Easy Installation and Fabrication

Thanks to its light weight — approximately one-third the weight of steel — fiberglass grating is easy to handle, transport, and install. It can be cut on-site using standard carbide tools, which eliminates the need for hot work permits or special equipment. This simplifies retrofitting and customization in complex plant layouts.

Specifiche e parametri tecnici delle griglie in FRP

1. General Specifications

| Articolo | Descrizione |

|---|---|

| Tipo di prodotto | Grigliato FRP stampato / Grigliato FRP pultruso |

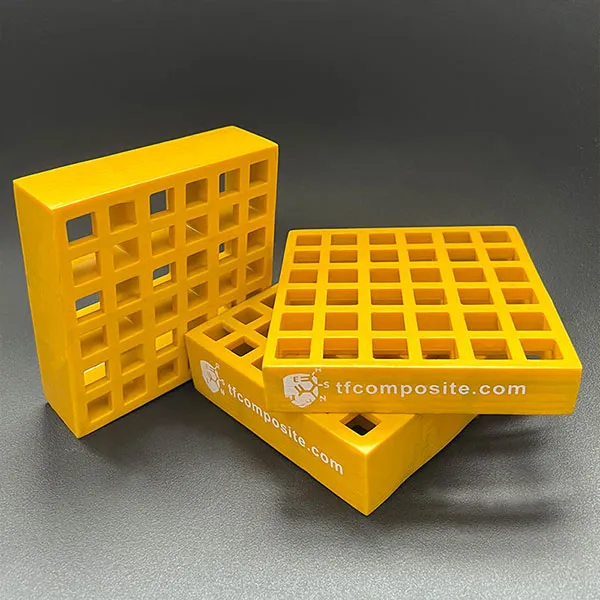

| Dimensione della maglia | 38×38 mm (1,5″x1,5″) / 40×40 mm / Personalizzato |

| Spessore (altezza) | 25 mm / 30 mm / 38 mm / 50 mm |

| Dimensioni del pannello | 1220×3660 mm / 1000×4000 mm / Personalizzato |

| Area aperta | 60% – 70% (a seconda della dimensione della maglia) |

| Opzioni di superficie | Superficie liscia / concava / ruvida / coperta |

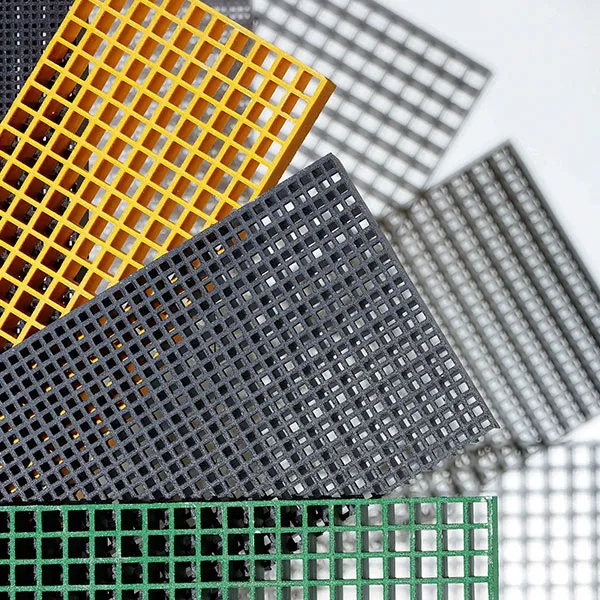

| Colore | Grigio, Giallo, Verde, Rosso, Personalizzato |

2. Proprietà meccaniche (valori tipici)

| Proprietà | Valore | Standard di prova |

|---|---|---|

| Resistenza alla trazione | ≥ 120 MPa (17.400 psi) | ASTM D638 |

| Resistenza alla flessione | ≥ 200 MPa (29.000 psi) | ASTM D790 |

| Modulo di flessione | ≥ 7.800 MPa (1,13×10⁶ psi) | ASTM D790 |

| Resistenza alla compressione | ≥ 200 MPa (29.000 psi) | ASTM D695 |

| Resistenza all'impatto (Izod) | ≥ 85 J/m | ASTM D256 |

| Durezza Barcol | ≥ 40 | ASTM D2583 |

3. Proprietà fisiche e chimiche

| Proprietà | Valore | Standard di prova |

|---|---|---|

| Densità | ~1,8–2,0 g/cm³ | ASTM D792 |

| Assorbimento d'acqua | < 0,5% | ASTM D570 |

| Resistenza alla fiamma | ≤ 25 (Classe 1) | ASTM E84 |

| Resistenza ai raggi UV | Disponibile con inibitore UV | – |

| Conduttività elettrica | Non conduttore | – |

| Conduttività termica | ~0,25 W/m·K | ASTM C177 |

| Intervallo di temperatura di esercizio | da -50°C a +120°C (varia a seconda della resina) | – |

4. Sistemi di resina disponibili

| Tipo di resina | Caratteristiche | Aree di applicazione |

|---|---|---|

| Ortoftalico | Uso generale, conveniente | Industria generale, pavimentazione |

| Isoftalico | Resistenza chimica migliorata | Acque reflue, lavorazione alimentare |

| Vinilestere | Eccellente resistenza chimica e alla corrosione | Impianti chimici, offshore, minerari |

| Fenolico | Resistenza al fuoco e al fumo | Petrolio e gas, trasporti, marina |

5. Tabella di carico (esempio per grigliato spesso 38 mm)

| Apertura (mm) | Carico (kN/m²) | Deflessione (mm) |

|---|---|---|

| 600 | 5.0 | 4.5 |

| 800 | 3.5 | 5.9 |

| 1000 | 2.0 | 7.6 |

Perché sceglierci

Competenza nella produzione di grigliati in FRP

Con oltre 20 anni di esperienza, il nostro stabilimento è specializzato esclusivamente nella progettazione, sviluppo e produzione di grigliati in FRP (plastica rinforzata con fibra di vetro) ad alte prestazioni. La nostra profonda conoscenza del settore garantisce che ogni prodotto soddisfi i più rigorosi standard industriali.

Tecnologia e attrezzature avanzate

Utilizziamo macchinari di produzione all'avanguardia e tecnologie di stampaggio di precisione per realizzare grigliati con resistenza, resistenza alla corrosione e precisione dimensionale superiori. Il nostro impegno per l'innovazione significa che il vostro progetto beneficia dei più recenti progressi nella tecnologia FRP.

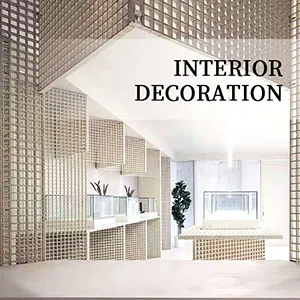

Soluzioni personalizzate

Dalle dimensioni dei pannelli e dai tipi di resina alle finiture e ai colori delle superfici, offriamo una personalizzazione completa per soddisfare le vostre specifiche esigenze applicative, che si tratti di pavimenti industriali, gradini di scale, coperture di trincee o piattaforme marine.

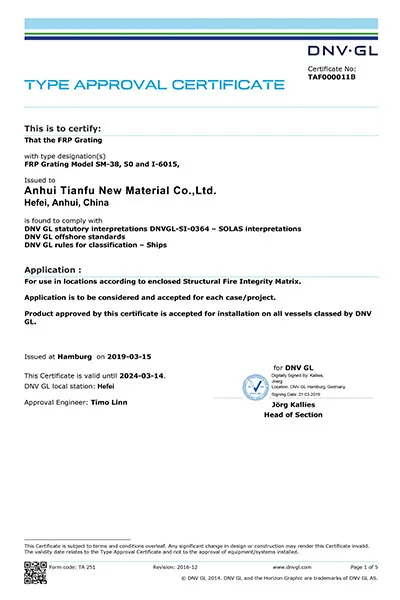

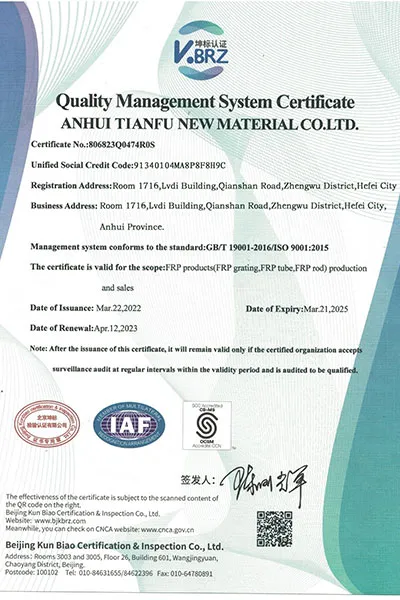

Controllo di qualità rigoroso

Ogni prodotto viene sottoposto a un rigoroso processo di controllo qualità, che include prove di carico, controlli di ignifugazione e analisi di resistenza alla corrosione. Il nostro sistema di gestione della qualità certificato ISO garantisce un'eccellenza costante in ogni lotto.

Prezzi competitivi

Offriamo prezzi di fabbrica diretti senza compromettere la qualità. Grazie a processi produttivi ottimizzati e capacità di produzione in serie, aiutiamo i nostri clienti a ottenere risparmi sui costi su larga scala.

Consegna affidabile e portata globale

Disponiamo di un ampio stock di prodotti standard e gestiamo un sistema logistico efficiente, garantendo tempi di consegna rapidi a livello locale e internazionale. Abbiamo servito con successo clienti in oltre 15 paesi.

Prodotti più venduti

| Dimensioni standard dei pannelli | 1220 mm × 3660 mm (4 piedi × 12 piedi) 1220 mm × 4000 mm (4 piedi × 13,1 piedi) 915 mm × 3050 mm (3 piedi × 10 piedi) 1000 mm × 3000 mm (personalizzabile) (Altre dimensioni possono essere personalizzate in base alle esigenze del progetto) |

| Opzioni di spessore | 25 mm (1 pollice) 30 mm (1,2 pollici) 38 mm (1,5 pollici) — il più comune 50 mm (2 pollici) |

| Dimensione della maglia (dimensione dell'apertura) | 38 mm × 38 mm (1,5 pollici × 1,5 pollici) — Standard 40 millimetri × 40 millimetri 19 mm × 19 mm (mini-maglia per impedire il passaggio di piccoli oggetti) |

| Larghezza e spaziatura della barra di carico (per grigliati pultrusi) | Larghezza della barra di carico: in genere 25 mm, 38 mm, 50 mm Distanza tra le barre di carico: 25 mm, 40 mm, 50 mm da centro a centro |

| Opzioni di superficie | Superficie granulata (antiscivolo) Superficie liscia Superficie coperta (piano superiore pieno) |

| Colori disponibili | Giallo (il più comune) Verde Grigio Rosso Colori personalizzati su richiesta |

| Tipi comuni di resina | Poliestere isoftalico (resistenza alla corrosione standard) Vinilestere (elevata resistenza chimica) Fenolico (applicazioni resistenti al fuoco) |

Informazioni sulla fabbrica

Anhui Tianfu New Material Co., Ltd è un produttore professionale leader specializzato in Grigliato stampato in FRP Produzione. Con oltre 20 anni di esperienza nel settore dei materiali compositi, ci dedichiamo alla fornitura di soluzioni in plastica rinforzata con fibra di vetro (FRP) di alta qualità per un'ampia gamma di applicazioni industriali e commerciali. Il nostro moderno stabilimento è dotato di linee di produzione avanzate e copre un'area di oltre 26.000 metri quadrati. Offriamo una gamma completa di grigliati stampati in FRP caratterizzati da resistenza superiore, resistenza chimica, ignifugazione e prestazioni antiscivolo. In Tianfu New Material, diamo priorità all'innovazione, al rigoroso controllo qualità e alla soddisfazione del cliente. I nostri prodotti sono certificati secondo gli standard internazionali ed esportati in oltre 30 paesi in tutto il mondo, servendo settori come impianti chimici, impianti di trattamento delle acque reflue, piattaforme offshore e passerelle. Che abbiate bisogno di dimensioni standard o soluzioni personalizzate, Tianfu è il vostro partner affidabile per i grigliati stampati in FRP.

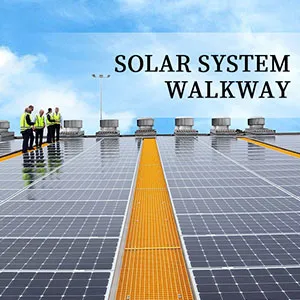

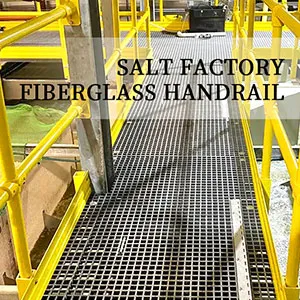

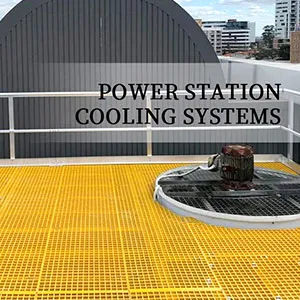

Scenari applicativi

Informazioni sulla fabbrica

Siamo un produttore professionale di grigliati in FRP con oltre 20 anni di esperienza. Il nostro stabilimento di 26.000 m² è certificato ISO9001 e serve clienti in oltre 30 paesi con capacità OEM/ODM. Offriamo soluzioni personalizzate e consegne rapide in tutto il mondo.

I nostri grigliati in FRP sono realizzati in conformità con gli standard ISO 9001 e testati secondo ASTM E84 (classe di resistenza al fuoco 1), ASTM D638/D790 per le prestazioni meccaniche e sono conformi agli standard BS 476 ed EN 13706. Su richiesta, sono disponibili test di terze parti tramite SGS e TUV.

Esposizione

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

Certificato

Grigliato stampato in FRP (scheda tecnica)

Altri prodotti

Tour della fabbrica VR

Fiberglass Grating Chemical Plants Power Stations Oil & Gas Refineries Industrial Flooring

applicazione

Pavimentazioni industriali, piattaforme marine e offshore, impianti di trattamento delle acque reflue, industria alimentare e delle bevande, infrastrutture di trasporto, cantieri edili, sale batterie e sottostazioni elettriche, spazi pubblici e commerciali, parchi acquatici e piscine, sistemi HVAC e sui tetti

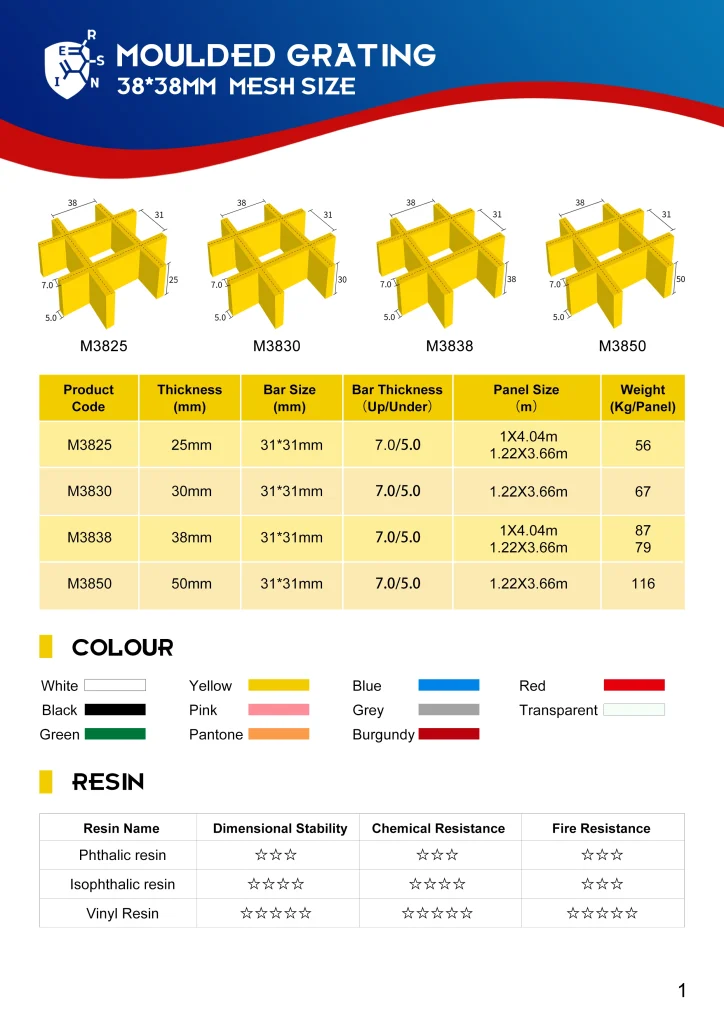

Dimensione della maglia:

38x38 millimetri (1,5

Spessore (Altezza):

25 mm / 30 mm / 38 mm / 50 mm

Dimensioni del pannello:

1220x3660 mm / 1000x4000 mm / Personalizzato

Area aperta:

60% – 70% (a seconda della dimensione della maglia)

Opzioni di superficie:

Superficie liscia / concava / ruvida / coperta

Colore :

Grigio, Giallo, Verde, Rosso, Personalizzato

FAQ

Q :

Why is fiberglass grating preferred for flooring in chemical plants?

UN :

Fiberglass grating is highly resistant to corrosive chemicals, acids, and alkalis—making it ideal for the harsh environments found in chemical processing plants. Unlike steel, it does not rust or require painting or galvanizing.

Q :

What types of fiberglass grating are best for chemical plant use?

UN :

Molded FRP grating is commonly used due to its excellent corrosion resistance and bi-directional strength. Vinyl ester resin is typically chosen in chemical plant environments because of its superior chemical and heat resistance.

Q :

Is fiberglass grating safe for employees walking in areas exposed to chemicals?

UN :

Yes. Most fiberglass grating comes with anti-slip surfaces, such as gritted or concave finishes, to prevent slips even in wet or chemically contaminated areas. Additionally, it’s non-conductive, enhancing safety near electrical equipment.

Q :

How much weight can fiberglass grating support?

UN :

Depending on the type and thickness, fiberglass grating can support medium to heavy foot traffic and equipment. Pultruded grating offers higher unidirectional strength, while molded grating provides strength in both directions. Always refer to the load tables provided by the manufacturer.

Q :

Will fiberglass grating degrade in extreme temperatures?

UN :

Fiberglass grating performs well across a wide temperature range. With the right resin system (e.g., vinyl ester or phenolic), it can withstand high heat and thermal cycling, common in chemical processing areas.

Q :

How is fiberglass grating maintained in chemical plants?

UN :

It requires minimal maintenance. Cleaning can be done using water or non-abrasive cleaners. Since it doesn't rust or peel, there’s no need for repainting or recoating, reducing long-term maintenance costs.

Q :

Can fiberglass grating be customized for complex chemical plant layouts?

UN :

Yes. FRP grating is easy to cut and fabricate on-site using standard tools. It’s lightweight and can be quickly shaped to fit around tanks, drains, pipes, and other structures, making installation fast and flexible.

Altri prodotti correlati