Introduzione alle prestazioni del prodotto

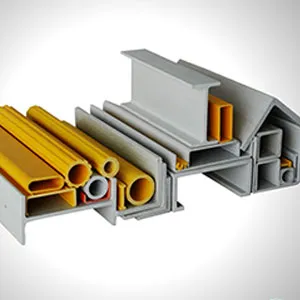

FRP (Fiber Reinforced Polymer) pipe is a high-performance composite pipe made from a combination of strong reinforcing fibers—typically glass, carbon, or aramid—embedded in a thermosetting resin matrix such as epoxy, vinyl ester, or polyester. This construction provides FRP pipes with excellent mechanical strength, corrosion resistance, and durability, making them ideal for use in demanding industrial and infrastructure applications.

One of the most significant advantages of FRP pipe is its superior corrosion resistance. Unlike steel or traditional metal pipes, FRP does not corrode when exposed to harsh chemicals, saltwater, or sewage. This makes it particularly suitable for use in chemical processing plants, desalination facilities, oil and gas pipelines, wastewater systems, and marine environments.

FRP pipes are also leggero, typically weighing only about 25–30% of steel pipes of the same diameter. This reduces transportation costs, eases handling, and simplifies installation. Despite being lightweight, they possess high tensile and compressive strength, allowing them to operate under high internal pressures and external loads.

Another benefit is the long service life of FRP pipes, which can exceed 50 years under normal operating conditions. They require little to no maintenance, contributing to a low lifecycle cost. FRP pipes also offer excellent thermal insulation and can be custom-fabricated in a wide range of diameters, thicknesses, and pressure ratings to meet specific project needs.

Common joining methods for FRP pipes include adhesive bonding, flanged joints, and mechanical couplings. The internal surface is often smooth, resulting in low friction losses and improved flow efficiency in fluid transport systems.

FRP Pipe Specifications & Technical Parameters

| Parametro | Description / Range |

|---|---|

| Composizione del materiale | Reinforcing fibers (Glass, Carbon, or Basalt) + Thermosetting resin (Polyester, Vinyl Ester, or Epoxy) |

| Manufacturing Methods | Filament Winding, Centrifugal Casting, Hand Lay-up |

| Nominal Diameter Range | 25 mm (1″) to 4000 mm (160″) |

| Wall Thickness | Typically 3 mm to 100 mm or more (based on pressure class) |

| Standard Pipe Lengths | 3 m, 6 m, 12 m (custom lengths available on request) |

| Colors | Green, Grey, or Custom (UV-protected topcoats optional) |

| Finitura superficiale | Smooth, resin-rich inner bore for low friction and corrosion resistance |

| Joint Types | Bell & Spigot with rubber rings, Flanged joints, Adhesive bonded, Threaded couplings |

FRP Pipe Technical Parameters

| Proprietà | Typical Values |

|---|---|

| Densità | 1.6 – 2.1 g/cm³ |

| Resistenza alla trazione | 100 – 300 MPa |

| Resistenza alla compressione | 100 – 250 MPa |

| Resistenza alla flessione | 150 – 400 MPa |

| Modulus of Elasticity | 10 – 25 GPa |

| Hydraulic Efficiency | High (smooth bore; Hazen-Williams C > 150) |

| Working Pressure Rating | 1 to 32 bar (up to 300 psi); custom up to 100 bar available |

| Burst Pressure | Typically ≥ 4x design pressure |

| Temperature Range | -40°C to +120°C (higher with special resin systems) |

| Thermal Conductivity | 0.2 – 0.4 W/m·K (good insulation properties) |

| Conduttività elettrica | Electrically non-conductive |

| Resistenza alla corrosione | Excellent—resists acids, alkalis, saltwater, and chemicals |

| Resistenza ai raggi UV | High (with UV-resistant resin or coating) |

| Resistenza al fuoco | Available with fire-retardant additives or resins |

| Expected Service Life | 50+ years under normal operating conditions |

Why Choose Us

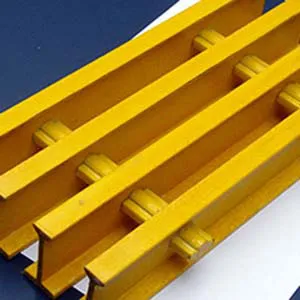

Expertise in FRP Grating Manufacturing

With over 20 years of experience, our factory specializes exclusively in the design, development, and production of high-performance FRP (Fiberglass Reinforced Plastic) gratings. Our deep industry knowledge ensures that every product meets the most demanding industrial standards.

Advanced Technology and Equipment

We utilize state-of-the-art manufacturing equipment and precision molding technology to produce gratings with superior strength, corrosion resistance, and dimensional accuracy. Our commitment to innovation means your project benefits from the latest advancements in FRP technology.

Customized Solutions

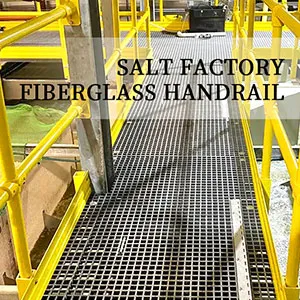

From panel sizes and resin types to surface finishes and colors, we offer complete customization to meet your unique application needs—be it industrial flooring, stair treads, trench covers, or marine platforms.

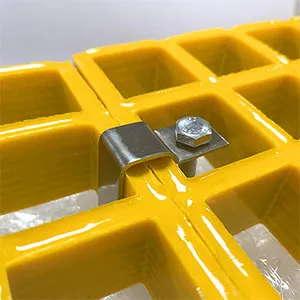

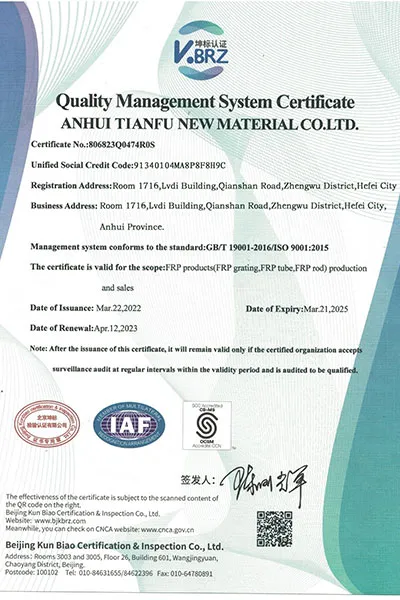

Stringent Quality Control

Every product undergoes a rigorous quality inspection process, including load testing, flame retardance checks, and corrosion resistance analysis. Our ISO-certified quality management system ensures consistent excellence in every batch.

Competitive Pricing

We offer factory-direct pricing without compromising on quality. With optimized production processes and bulk manufacturing capabilities, we help our customers achieve cost savings at scale.

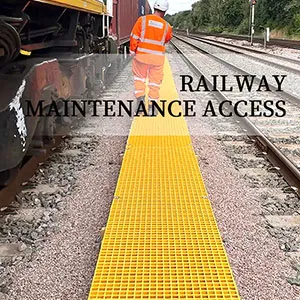

Reliable Delivery and Global Reach

We maintain a large stock of standard products and operate a streamlined logistics system, ensuring fast delivery times locally and internationally. We’ve successfully served clients in over 15 countries.

Hot-Selling Products

Application Scenarios

About the Factory

We are a professional FRP Grating manufacturer with 20+ years of experience. Our 26,000㎡ factory is ISO9001 certified, serving clients across 30+ countries with OEM/ODM capability. We provide customized solutions and fast delivery worldwide.

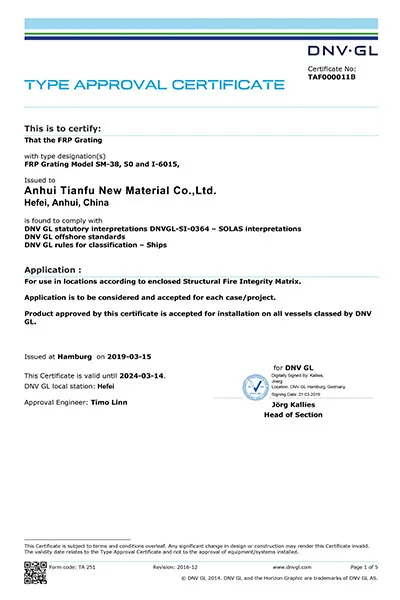

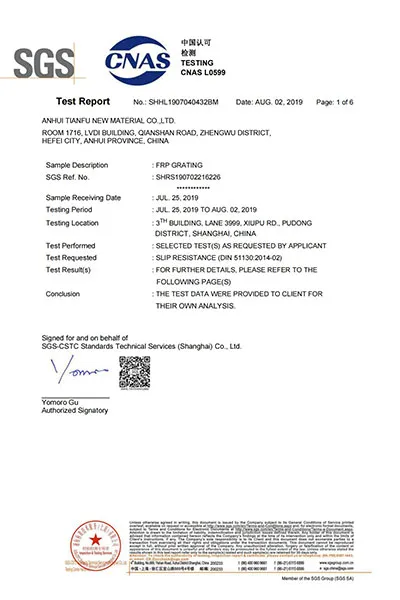

Our FRP gratings are manufactured in accordance with ISO 9001 standards and tested per ASTM E84 (Class 1 fire rating), ASTM D638/D790 for mechanical performance, and comply with BS 476 and EN 13706 standards. Third-party testing available through SGS and TUV upon request.

Esposizione

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

Certificate

Other Products

VR Factory Tour

Tubo in FRP

Serie:

Tubo in FRP >applicazione

Chemical processing plants Desalination and water treatment systems Oil & gas industry Marine and offshore platforms Power plants (especially cooling water lines) Sewage and wastewater systems

Material Composition :

Reinforcing fibers (Glass, Carbon, Basalt) + Resin matrix (Polyester, Vinyl Ester, Epoxy)

Manufacturing Methods :

Filament Winding, Centrifugal Casting, Hand Lay-up

Standard Diameters :

25 mm (1

Wall Thickness :

3 mm to 100+ mm (based on pressure & structural requirements)

Length of Pipe :

Typically 6 m or 12 m; custom lengths available

Colore :

Grey, green, or customized (UV-stabilized coatings optional)

FAQ

Q :

What are the advantages of FRP pipe over steel or PVC?

UN :

Excellent corrosion resistance Lightweight and easy to handle High mechanical strength Long service life (50+ years) Non-conductive (electrical insulation) Low thermal conductivity Reduced installation and maintenance costs

Q :

What sizes are available for FRP pipes?

UN :

Standard sizes range from 25 mm to 4000 mm in diameter. Lengths are typically 6 or 12 meters, with custom sizes available on request.

Q :

Is FRP pipe resistant to corrosion and chemicals?

UN :

Yes, FRP pipes offer excellent resistance to a wide range of chemicals, including acids, alkalis, saltwater, and hydrocarbons. Resin selection (e.g., vinyl ester) further enhances chemical compatibility.

Q :

How is FRP pipe joined?

UN :

Bell & spigot with rubber rings Flanged connections Adhesive bonding Threaded couplings (for smaller sizes)

Q :

Can FRP pipe be used for high-pressure systems?

UN :

Yes. FRP pipes can be designed for pressure ratings up to 32 bar (450 psi) or more, depending on wall thickness and winding design.

Q :

What is the temperature range for FRP pipe?

UN :

Standard operating range is -40°C to +120°C. With special resins (like epoxy), it can go up to 180°C.

Q :

Is FRP pipe UV resistant?

UN :

Yes, when manufactured with UV-resistant resin systems or protective coatings, FRP pipes can withstand prolonged exposure to sunlight.

Q :

Is FRP pipe safe for potable (drinking) water?

UN :

Yes, FRP pipe systems using NSF/ANSI 61-certified materials are approved for use in potable water applications.

Altri prodotti correlati