Introdução ao desempenho do produto

Introdução

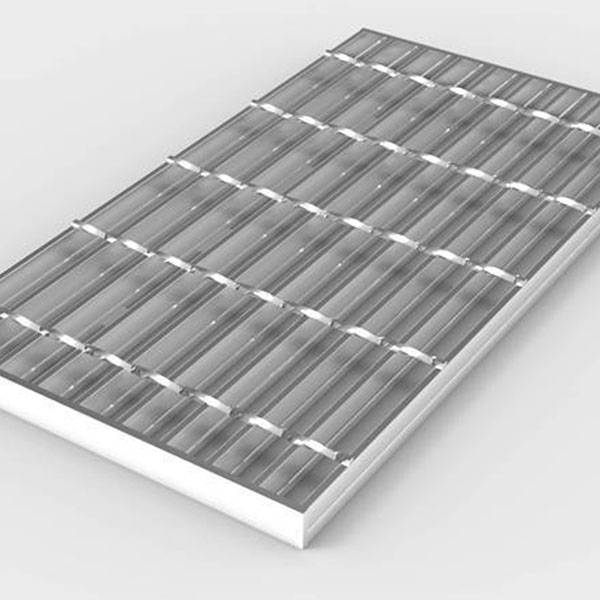

A grade rebitada é um tipo especializado de grade de aço caracterizada por sua excepcional resistência e durabilidade. Ao contrário das grades soldadas ou prensadas, a grade rebitada é construída rebitando-se as barras de sustentação às barras transversais reticuladas, criando uma estrutura robusta e estável. Esse método de construção a torna adequada para aplicações de alta exigência, principalmente em ambientes com cargas e forças de impacto significativas.

Este documento apresenta as especificações detalhadas, modelos, dimensões e outras informações essenciais sobre grades rebitadas.

1. Especificações da Grelha Rebitada

Composição do material

-

Aço carbonoOferece excelente resistência e durabilidade para aplicações com cargas pesadas.

-

Aço inoxidávelOferece resistência superior à corrosão, ideal para ambientes corrosivos e marinhos.

-

Aço galvanizadoGalvanizado a quente para maior proteção contra corrosão.

-

AlumínioLeve, resistente à corrosão e adequado para aplicações que exigem peso mínimo.

Opções de tratamento de superfície

-

Galvanização por imersão a quenteO tratamento mais comum para garantir resistência à corrosão e prolongar a vida útil.

-

Revestimento em póAdiciona uma camada protetora com diversas opções de cores.

-

Acabamento de fábricaOferece um acabamento em aço liso, adequado para aplicações internas.

-

Revestimento de tintaOferece proteção adicional e personalização estética.

Processo de rebitagem

-

As barras de suporte e as barras transversais são rebitadas entre si utilizando máquinas de rebitagem hidráulicas ou mecânicas.

-

Isso cria uma conexão segura, melhorando a distribuição de carga e a durabilidade.

2. Modelos e Tipos

Com base no perfil da barra de apoio

-

Grelha rebitada de barra planaOferece capacidade máxima de carga.

-

Grelha rebitada em forma de IProporciona uma estrutura mais leve com menor utilização de materiais.

-

Grelha rebitada com barra serrilhadaAumenta a resistência ao deslizamento em ambientes molhados ou escorregadios.

Com base na capacidade de carga

-

Grelha rebitada de serviço padrãoAdequado para tráfego de pedestres e cargas leves de veículos.

-

Grelha rebitada reforçadaProjetado para aplicações industriais e veiculares.

Com base no aplicativo

-

Grelha Industrial RebitadaUtilizado em fábricas, usinas e armazéns.

-

Grade do tabuleiro da ponteSuporta cargas veiculares pesadas em pontes e passarelas.

-

Grelha de cobertura de vala: Comumente utilizado em sistemas de drenagem.

3. Dimensões

Dimensões da barra de apoio

-

Espessura: Normalmente varia de 3 mm a 12 mm.

-

Altura: As alturas comuns incluem 25 mm, 30 mm, 40 mm e 50 mm.

-

Largura: Varia de 20 mm a 150 mm, dependendo da aplicação.

Dimensões da barra transversal

-

Largura: Normalmente 5 mm a 10 mm.

-

Espaçamento: O espaçamento padrão varia de 50 mm a 100 mm.

Tamanhos dos painéis

-

Painel padrão: 1.000 mm x 6.000 mm.

-

Tamanhos personalizados: Disponíveis mediante solicitação para projetos específicos.

4. Considerações de projeto

-

Requisitos de cargaCertifique-se de que a espessura e o espaçamento da barra de apoio escolhida sejam suficientes para suportar a carga prevista.

-

Resistência à corrosãoPara ambientes externos ou corrosivos, recomenda-se o uso de aço galvanizado ou inoxidável.

-

Anti-derrapanteAs barras de apoio serrilhadas melhoram a segurança em áreas expostas à umidade.

-

Apelo estéticoGrelhas rebitadas com revestimento em pó ou pintadas podem melhorar o apelo visual.

5. Aplicações de grades rebitadas

-

Plataformas IndustriaisOferece pisos duráveis para áreas com máquinas pesadas.

-

Tabuleiro da ponteSuporta tráfego de veículos e pedestres.

-

Passarelas e PassagensGarante a segurança em ambientes elevados.

-

Tampas de valas e sistemas de drenagemPermite uma drenagem de água eficiente.

-

Estruturas Marinhas e OffshoreResistente às condições marítimas adversas.

Conclusão

As grades rebitadas são uma opção robusta e confiável para aplicações exigentes. Sua resistência superior, durabilidade e capacidade de carga as tornam adequadas para projetos industriais, de transporte e de infraestrutura. Ao selecionar o material, o tratamento de superfície e as dimensões apropriadas, os usuários podem garantir desempenho ideal e longa vida útil em suas aplicações.

Grade rebitada

Series :

Produtos proxy >aplicativo

Plataformas industriais: Oferecem pisos duráveis para áreas com máquinas pesadas. Tabuleiros de pontes: Suportam tráfego de veículos e pedestres. Passarelas e caminhos elevados: Garantem a segurança em ambientes elevados. Tampas de valas e sistemas de drenagem: Permitem a drenagem eficiente da água. Estruturas marítimas e offshore: Resistentes às condições marítimas adversas.

Perguntas frequentes

Outros produtos relacionados