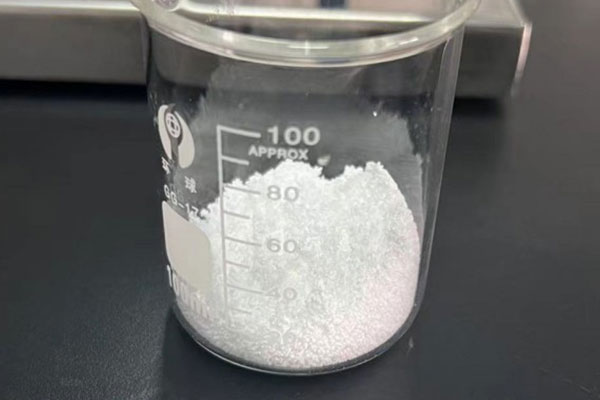

Benzoyl Peroxide (BPO) Granules are a stabilized, granular form of benzoyl peroxide, widely utilized as a polymerization initiator and curing agent in various industrial applications. This form offers enhanced safety, ease of handling, and consistent performance compared to other forms like powders or pastes.

Introdução ao desempenho do produto

1. Chemical Identity

-

Nome químico: Benzoyl Peroxide

-

Número CAS: 94-36-0

-

Molecular Formula: C₁₄H₁₀O₄

-

Molecular Weight: 242.23 g/mol

-

Synonyms: Dibenzoyl Peroxide, BPO, Benzoic Peroxyanhydride

2. Physical and Chemical Properties

| Propriedade | Valor |

|---|---|

| Aparência | White granular solid |

| Odor | Faint odor of benzaldehyde |

| Ponto de fusão | 103–106 °C |

| Densidade | 1.16 g/cm³ at 25 °C |

| Solubility in Water | Insoluble |

| Solubility in Organic Solvents | Soluble in acetone, benzene, chloroform; slightly soluble in ethanol |

| Ponto de inflamação |

|

| Decomposition Temperature | 131 °C (1-minute half-life) |

| Theoretical Active Oxygen Content | 6.62% |

3. Technical Data Sheet (TDS)

3.1. Product Specifications

| Parâmetro | Especificação |

|---|---|

| Assay (BPO Content) | 72–76% |

| Water Content | 22–25% |

| Free Chloride | ≤0.1% |

| Free Acid (as Benzoic Acid) | ≤0.5% |

| Aparência | White granular solid |

| Densidade aparente | 500–600 kg/m³ |

3.2. Thermal Decomposition Data

| Half-Life | Temperatura |

|---|---|

| 10 hours | 73 °C |

| 1 hour | 92 °C |

| 1 minute | 131 °C |

4. Aplicações

4.1. Polymer Industry

-

Initiator for Polymerization: BPO granules are extensively used to initiate the polymerization of monomers such as styrene, methyl methacrylate, and acrylates in the production of plastics, resins, and adhesives.

4.2. Composite Materials

-

Curing Agent: In unsaturated polyester and vinyl ester resins, BPO granules act as a curing agent, facilitating cross-linking during the fabrication of fiberglass-reinforced plastics.

4.3. Rubber Industry

-

Vulcanizing Agent: BPO granules serve as a vulcanizing agent and cross-linking agent for silicone rubber and fluorine rubber.3bf12b2b2d28ef1b.en.made-in-china.com

5. Safety and Handling

5.1. Hazards Identification

-

Oxidizing Agent: BPO granules are strong oxidizers and can pose fire and explosion hazards, especially when dry or in contact with combustible materials.

-

Health Hazards: Exposure may cause skin and eye irritation. Inhalation of dust can irritate the respiratory tract.

5.2. Exposure Limits

-

NIOSH Recommended Exposure Limit (REL): TWA 5 mg/m³

-

OSHA Permissible Exposure Limit (PEL): TWA 5 mg/m³

-

Immediately Dangerous to Life or Health (IDLH): 1500 mg/m³

5.3. Personal Protective Equipment (PPE)

-

Eye Protection: Safety goggles or face shield

-

Skin Protection: Protective gloves and clothing

-

Respiratory Protection: Dust mask or respirator in case of inadequate ventilation

5.4. First Aid Measures

-

Inhalation: Move to fresh air. Seek medical attention if symptoms persist.

-

Skin Contact: Wash with soap and water. Remove contaminated clothing.

-

Eye Contact: Rinse cautiously with water for several minutes. Seek medical advice.

-

Ingestion: Do not induce vomiting. Seek immediate medical attention.

6. Storage and Stability

-

Condições de armazenamento: Store in a cool, dry, well-ventilated area away from heat sources and direct sunlight.

-

Temperature: Maintain storage temperature below 35 °C.

-

Embalagem: Typically available in 20 kg or 25 kg containers with inner polyethylene bags and outer fiber drums or cartons.

-

Stability: BPO granules are stable under recommended storage conditions but decompose upon heating, shock, or friction.

7. Regulatory Information

-

UN Number: 3104 (for BPO with ≥52% content)

-

Hazard Class: 5.2 (Organic Peroxides)

-

Packing Group: II

-

Regulatory Listings: BPO is listed under various regulatory frameworks, including REACH, TSCA, and OSHA.

8. Environmental Impact

-

Ecotoxicity: BPO is harmful to aquatic life with long-lasting effects.

-

Degradability: It decomposes into benzoic acid and oxygen, which can contribute to environmental oxygen demand.

grânulos de BPO

Series :

Produtos proxy >aplicativo

5.1. Polymer Industry Initiator for Polymerization: BPO is widely used to initiate the polymerization of monomers like styrene, methyl methacrylate, and acrylates in the production of plastics, resins, and adhesives. 5.2. Composite Materials Curing Agent: In unsaturated polyester and vinyl ester resins, BPO acts as a curing agent, facilitating cross-linking during the fabrication of fiberglass-reinforced plastics. 5.3. Pharmaceuticals and Cosmetics Acne Treatment: BPO is a common active ingredient in topical acne medications due to its antibacterial properties. 5.4. Food Industry Bleaching Agent: BPO is employed to bleach flour, whey, and cheese products, improving their appearance.

Marca :

TFcomposite

Nome do Produto :

grânulos de BPO

Perguntas frequentes

P:

Para que serve a pasta BPO na indústria de fibra de vidro?

A :

A pasta de BPO (peróxido de benzoíla) é usada principalmente como iniciador de cura para resinas de poliéster insaturadas e vinil éster. Ela auxilia no início do processo de polimerização em diversos métodos de fabricação de fibra de vidro, como laminação manual, projeção, pultrusão, fundição e enrolamento de filamentos.

P:

Por que o BPO é usado em forma de pasta em vez de pó?

A :

Mais seguro (menor risco de explosão ou incêndio), mais fácil de manusear e misturar, menos poeira, mais estável durante o armazenamento e transporte.

P:

A pasta de BPO pode ser usada sozinha para cura?

A :

Não. A pasta de BPO requer um promotor/acelerador — geralmente octoato de cobalto — para se decompor adequadamente e gerar radicais livres para a cura.

P:

Qual é a dosagem típica de pasta de BPO na produção de fibra de vidro?

A :

A dosagem padrão geralmente varia de 1,0% a 2,5% em peso de resina, dependendo do tipo de resina, da velocidade de cura necessária e da temperatura.

Outros produtos relacionados