Fiberglass Fabric e Fita de fibra de vidro are widely used reinforcement materials feito de woven fiberglass yarns, primarily Vidro E (alkali-free glass) or óculos de realidade aumentada (alkali-resistant glass). These materials are known for their força, durabilidade, e high-temperature resistance. Both fiberglass fabric e fiberglass tape are primarily used for reforço composto, isolamento, aplicações elétricas, e corrosion protection.

Introdução ao desempenho do produto

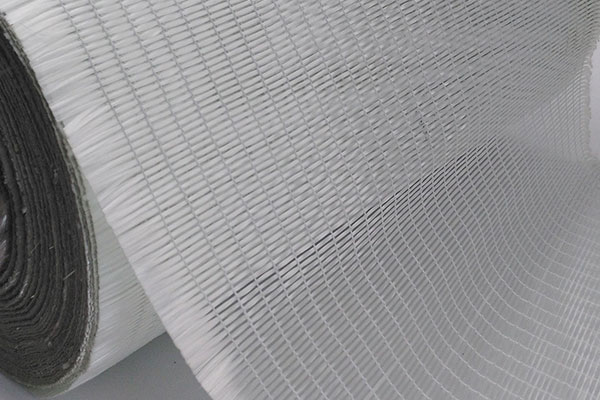

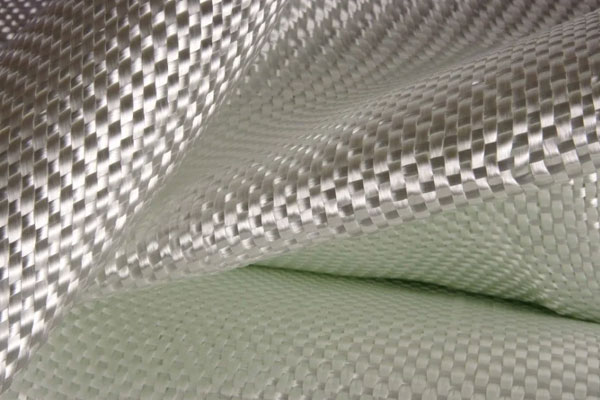

Fiberglass fabric is typically a woven textile composto por continuous filaments of glass fiber, which gives it remarkable strength and flexibility. It is available in different weave patterns (plain, twill, satin) and weights (gsm) to suit various applications. Fiberglass tape is essentially a narrow width of fiberglass fabric, designed for use in wrapping, insulating, ou reforçando a variety of products, such as tubos, joints, electrical components, e composite parts.

Both fiberglass fabric and tape are compatible with a wide range of resinas, incluindo epóxi, poliéster, e éster vinílico, and they are used in processes such as lamination, infusão a vácuo, RTM (Resin Transfer Molding), e bandeja manual for creating composite parts. They also provide excellent thermal resistance e estabilidade química, making them suitable for applications exposed to high temperatures and corrosive environments.

🧪 Dados técnicos típicos (estilo TDS)

| Parâmetro | Valor típico / intervalo |

|---|---|

| Nome do produto | Fiberglass Fabric / Fiberglass Tape |

| Tipo de fibra | E-glass (alkali-free), AR-glass (alkali-resistant) |

| Weave Type (Fabric) | Plain, Twill, Satin (customizable) |

| Tape Width | 10 mm – 100 mm (customizable) |

| Density / Weight (Fabric) | 100 gsm – 1000 gsm (customizable) |

| Grossura | 0.1 mm – 1.5 mm (depending on weight and type) |

| Resistência à tracção | 2000 – 4000 N/50 mm (depending on fiber type and weave) |

| Teor de umidade | ≤ 0,2% |

| Perda por Ignição (LOI) | 0,5% – 1,5% |

| Compatibilidade de resina | Polyester, Epoxy, Vinyl Ester, Phenolic |

| Width (Fabric) | 1000 mm, 1270 mm, 2000 mm (personalizável) |

| Comprimento do rolo | 50 a 100 metros |

| Cor | White, Off-white (custom colors possible) |

| Prazo de validade | 12 meses em condições adequadas de armazenamento. |

| Resistência ao fogo | Flame retardant (depending on resin system) |

✅ Principais características e benefícios

-

Alta resistência mecânica

Fiberglass fabric provides outstanding tensile strength, ensuring excellent reinforcement for composite structures. It has a high relação resistência/peso, which makes it ideal for lightweight, strong applications like automotivo components and aeroespacial parts. -

Excellent Thermal Resistance

Both fiberglass fabric and tape exhibit exceptional resistance to high temperatures, capable of withstanding temperatures up to 550°C without degradation. This makes them suitable for high-temperature insulation applications, such as in fornos, turbines, e industrial equipment. -

Chemical and Corrosion Resistance

Fiberglass materials offer superior resistance to a wide range of chemicals, including acids, alkalis, oils, and solvents, making them ideal for ambientes corrosivos como fábricas químicas, aplicações marítimas, e oil & gas pipelines. -

Isolamento elétrico

Fiberglass is an excellent electrical insulator, and both fiberglass fabric and tape are widely used in the electrical industry para insulating cables, transformers, e electrical components. They provide high dielectric strength e low moisture absorption, which enhances their electrical insulating properties. -

Lightweight and Flexible

Despite its strength, fiberglass fabric and tape are extremely leve. This makes them ideal for estruturas compostas leves that require high performance but must also maintain a low overall weight, such as in pás de turbina eólica e aircraft structures. -

Fácil de trabalhar

Both fiberglass fabric and tape are easy to handle and install. Fiberglass tape, in particular, can be wrapped around pipes, joints, ou electrical components for insulation or reinforcement purposes. The fabric is highly adaptable to a variety of molding processes and can conform to complex shapes, which makes it suitable for customized composite parts. -

Versatile and Customizable

Fiberglass fabric and tape are available in various weights, weave patterns, e widths, providing customization for different applications. This allows for tailored solutions to meet specific força, flexibilidade, ou compatibilidade da resina requirements.

🏭 Formulários

Fiberglass Fabric e Fita de fibra de vidro are used in a wide range of industries for various applications, including:

-

Aeroespacial: Aircraft fuselage panels, wing components, and reinforcement of internal parts.

-

Automotivo: Lightweight structural reinforcement, such as body panels, bumpers, and chassis.

-

Marinho: Boat hulls, decks, and underwater components requiring corrosion resistance and strength.

-

Construção: Reinforced concrete, building facades, and fireproof insulation.

-

Elétrica: Insulation of cables, transformers, and electrical equipment, especially in high-voltage applications.

-

Industrial: High-temperature applications like pipes, ducts, tanks, and industrial ovens.

-

Petróleo e gás: Corrosion protection for pipelines and tanks, as well as high-temperature insulation.

-

Energia Eólica: Reinforcement of wind turbine blades and other structural components.

-

Equipamentos esportivos: Reinforced composite components in bicycles, skis, and other sports gear.

📦 Embalagem e armazenamento

-

Embalagem: Fiberglass fabric and tape are typically packaged in rolos, which are wrapped in filme plástico ou papel kraft to protect them from dirt, moisture, and damage during transit. The rolls are wound tightly to prevent fiber breakage.

-

ArmazenarArmazene em um cool, dry, and well-ventilated area. Avoid exposure to direct sunlight or high humidity, as these conditions may compromise the material’s properties.

-

Prazo de validade: Fiberglass fabric and tape have a shelf life of 12 meses under proper storage conditions, though they can last longer if kept in ideal conditions.

🏅 Conformidade e Certificações

-

ASTM D578 – Especificação padrão para tecidos de fibra de vidro e tapes Utilizado em aplicações de compósitos.

-

ISO 9001 – Quality management system certification, ensuring consistent product quality and manufacturing processes.

-

Em conformidade com a RoHS – Free from hazardous substances such as lead, cadmium, e mercury.

-

UL (Underwriters Laboratories) – Certification for flame resistance e isolamento elétrico propriedades.

🛠 Opções de personalização

-

Weave Types (Fabric): Plain, twill, satin, or custom weaves based on required força, flexibilidade, e aparência.

-

Tape Width: Customizable from 10 mm to 100 mm, depending on application needs.

-

Peso e espessura: Customizable gsm for fabric, with a typical range of 100 gsm to 1000 gsm.

-

Tipos de fibra: Vidro E (standard) and óculos de realidade aumentada (alkali-resistant) options available based on application.

-

Compatibilidade de resina: Compatible with poliéster, epóxi, éster vinílico, e fenólico resins for composite applications.

🌍 Sustainability and Environmental Impact

Fiberglass fabric and tape are considered environmentally friendly materials due to their longa vida útil, recyclability, e minimal environmental impact during manufacturing. They are increasingly being used in applications aimed at improving energy efficiency e reducing carbon footprints, como em pás de turbina eólica e solar panels.

Fita de fibra de vidro

Series :

Tecido de fibra de vidro >aplicativo

Perguntas frequentes

P:

Qual a diferença entre tecido de fibra de vidro e fita de fibra de vidro?

A :

Tecido de fibra de vidro: Um tecido trançado disponível em vários tamanhos e espessuras, comumente usado para reforçar peças compostas, isolamento e proteção térmica. Fita de fibra de vidro: Uma faixa estreita de tecido de fibra de vidro, tipicamente de 10 mm a 100 mm de largura, usada principalmente para envolver, isolar e reforçar aplicações, especialmente em torno de tubos, componentes elétricos e juntas.

P:

What are the key properties of fiberglass tape?

A :

Fiberglass tape has the following key properties: High tensile strength: Provides excellent reinforcement, ensuring durability and structural integrity. Heat resistance: Can withstand high temperatures, typically up to 550°C, depending on the type of resin or finish used. Electrical insulation: Offers high dielectric strength and low moisture absorption, making it ideal for electrical insulation applications. Chemical resistance: Resistant to a wide range of chemicals, including acids, alkalis, oils, and solvents. Lightweight: Despite its strength, fiberglass tape is lightweight, making it ideal for low-weight reinforcement. Fire resistance: Naturally fire-resistant, it provides heat protection and does not ignite easily.

P:

How is fiberglass tape used for insulation?

A :

Fiberglass tape is used for insulating by wrapping it around pipes, wires, electrical components, or any other objects requiring heat or electrical insulation. The tape can either be applied directly to the surface or used in combination with other insulation materials for added protection. It is typically bonded with a resin or adhesive to improve durability.

Outros produtos relacionados