Visão Geral do Projeto

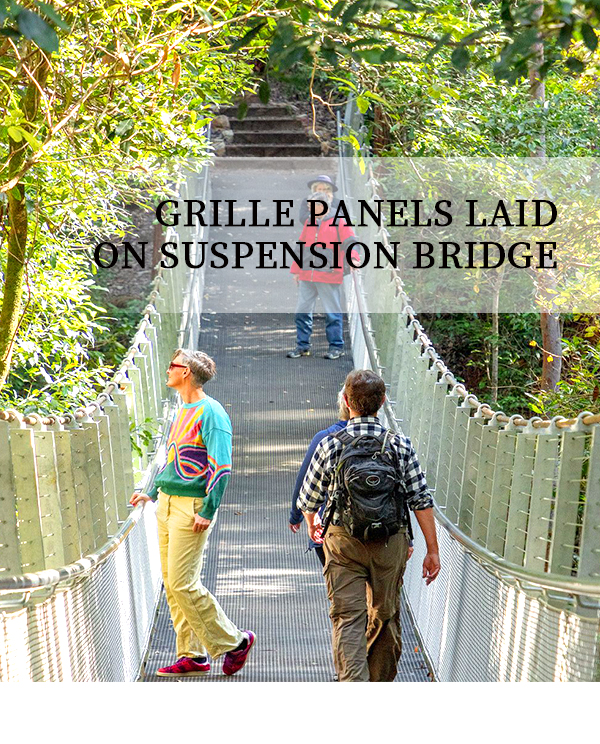

In 2023, a scenic eco-tourism park located in a mountainous region of Yunnan Province, China, undertook the construction of a new pedestrian suspension bridge spanning 80 meters across a deep forest valley. The client required a decking solution that was leve, durable, safe for high pedestrian traffic, and able to withstand extreme outdoor environmental conditions. After evaluating various materials including steel, wood, and composite options, the project team chose FRP (Fiber Reinforced Plastic) grating panels as the primary decking material.

Why FRP Grating Panels Were Chosen

Several key factors led to the selection of FRP grating panels for this suspension bridge:

1.Lightweight Structure:

Suspension bridges are sensitive to dead load. FRP grating is about 75% lighter than steel and significantly lighter than concrete or hardwood. This reduced the structural load on the suspension cables and towers, enabling a more economical and efficient bridge design.

2.High Strength and Load Capacity:

The selected FRP panels had a load-bearing capacity of over 500 kg/m², sufficient to support heavy pedestrian traffic and occasional maintenance equipment. The grating structure distributes weight evenly across the span, ensuring stability and safety.

3.Resistência à corrosão:

Given the high humidity, frequent rain, and biological exposure in the mountainous forest environment, corrosion resistance was a major concern. FRP’s inherent resistance to moisture, UV, and microbial growth ensured long-term durability with minimal degradation or maintenance.

4.Slip Resistance and Safety:

To ensure user safety in all weather conditions, the FRP grating panels were manufactured with a molded-in gritted surface, providing excellent slip resistance even in wet or muddy conditions. In addition, the panels were specified in a bright yellow color for increased visibility and aesthetic integration with the surrounding landscape.

5.Facilidade de instalação:

Due to the remote location, all materials had to be transported via narrow trails and assembled on-site without heavy machinery. FRP’s light weight and ease of cutting/drilling using hand tools allowed the local construction team to complete the decking quickly and efficiently.

Design and Customization

The decking consisted of 38 mm thick FRP molded grating with a 38×38 mm mesh, laid over cross beams spaced at regular intervals. To enhance aesthetics and safety, anti-slip nosing strips e side kick plates were added. The panels were bolted to the steel substructure with corrosion-resistant fasteners. The bridge also featured FRP handrails and toe guards to create a uniform, low-maintenance system.

Performance and Feedback

Since opening to the public, the bridge has become a highlight of the park, praised for its modern design, safety, and environmental harmony. Maintenance reports over the first year show no visible wear, corrosion, or structural concerns, even after exposure to heavy rainfall and UV radiation.

Park management reported that cleaning is simple, requiring only water spray, and there have been no incidents of slipping or surface damage, validating the safety features of the FRP panels. Visitors have also responded positively to the anti-slip surface and the bridge’s slight transparency, which adds to the thrill of walking across the valley.

Conclusão

This case demonstrates the outstanding performance of FRP grating panels as a suspension bridge decking solution. Their unique combination of lightweight strength, safety, corrosion resistance, and easy installation makes them an ideal choice for modern pedestrian bridge projects, especially in remote or environmentally sensitive areas. This successful application reinforces the role of FRP composites in sustainable infrastructure development.