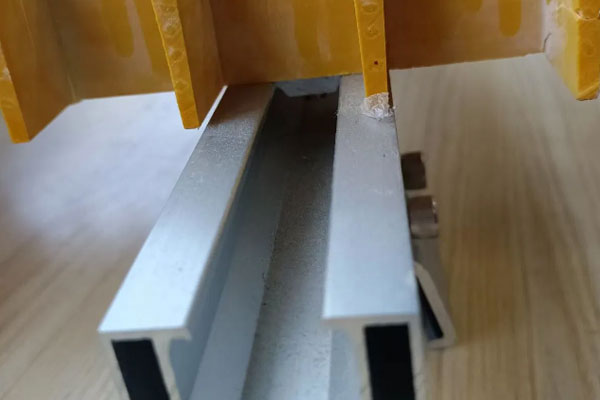

O Solar Maintenance Walkway Rails - 2000 Series are specially designed safety and access systems tailored for photovoltaic (PV) solar farms and rooftop installations. These rails offer a non-invasive, secure, and modular walking platform for maintenance personnel. Their lightweight yet robust construction ensures long-term durability in various weather conditions without compromising panel performance or roof integrity.

Introdução ao desempenho do produto

Technical Data Sheet:

| Recurso | Especificação |

|---|---|

| Modelo | Solar Walkway Rail – 2000 Series |

| Material | Marine-grade aluminum alloy / HDG Steel / FRP (options) |

| Acabamento de superfície | Anti-slip serrated / sanded / ribbed |

| Dimensions (Standard) | Length: 3000 mm (customizable) Width: 600 mm Height: 40 mm |

| Peso | ~8-12 kg per meter (depends on material) |

| Classificação de carga | ≥ 2.5 kN/m² uniformly distributed load |

| Fixing Type | Clamp-on / Non-penetrative for rooftop or direct-bolt for ground arrays |

| Compatibility | Compatible with most tilt-rack solar mounting systems |

| Resistência UV | Yes (UV-stabilized materials for outdoor use) |

| Resistência à corrosão | High (ideal for coastal or desert environments) |

| Opções de cores | Yellow, Gray, Black (standard); Custom on request |

| Optional Accessories | Guardrails, Kickplates, Toe boards, Walkway connectors |

| Certificações | ISO 9001, CE, OSHA compliant |

Formulários:

-

Ground-mounted and rooftop solar farms

-

Commercial and industrial PV systems

-

Flat roof solar installations

-

Utility-scale solar parks

Key Benefits:

-

Safety: Anti-slip surface and optional safety rails improve worker safety.

-

Durabilidade: Engineered to withstand extreme UV exposure, rain, snow, and sand.

-

Facilidade de instalação: Modular and lightweight design reduces labor and installation time.

-

Eco-friendly: 100% recyclable materials with low maintenance.

Solar maintenance walkway rails

Series :

supporting equipment >aplicativo

Industrial platforms and walkways Drainage trench covers Cooling tower floors Offshore installations Architectural facades Food and beverage plants

Marca :

TFcomposite

Nome do Produto :

Molded Grille Machinery

Perguntas frequentes

P:

How is molded grating different from pultruded grating?

A :

Molded grating is made by pouring resin over fiberglass mats in a mold, resulting in a bidirectional strength pattern. Pultruded grating is made by pulling continuous fiberglass strands through a resin bath and a heated die, offering higher longitudinal strength.

P:

What type of press is used in molded grille production?

A :

A hydraulic compression press with heated platens is most commonly used. Press capacity ranges from 500 to 1500 tons, depending on the grille size and thickness.

P:

What materials can the machinery handle?

A :

The machinery is compatible with: Fiberglass (E-glass or S-glass) Resins (polyester, vinyl ester, epoxy, phenolic) Additives like UV inhibitors, pigments, and flame retardants

P:

How are molds designed for different grille sizes?

A :

Molds are custom-fabricated based on required: Mesh patterns (square, rectangular) Panel thickness (e.g., 25 mm, 38 mm, 50 mm) Grille surface type (concave, gritted, plain)

P:

What’s the typical cycle time for one molded grille panel?

A :

The complete cycle—from lay-up to demolding—usually takes 30–90 minutes, depending on panel size, resin type, and curing system.

Outros produtos relacionados