การแนะนำประสิทธิภาพของผลิตภัณฑ์

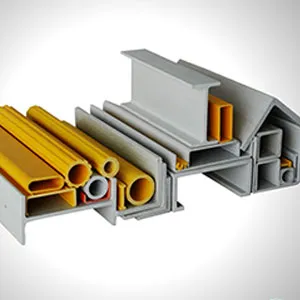

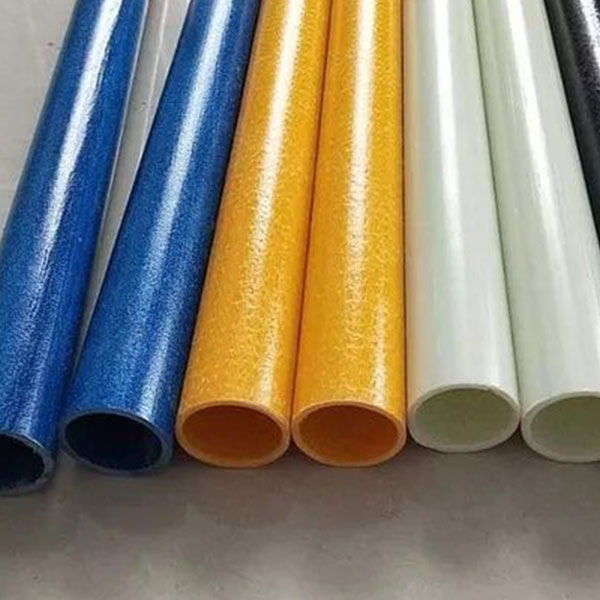

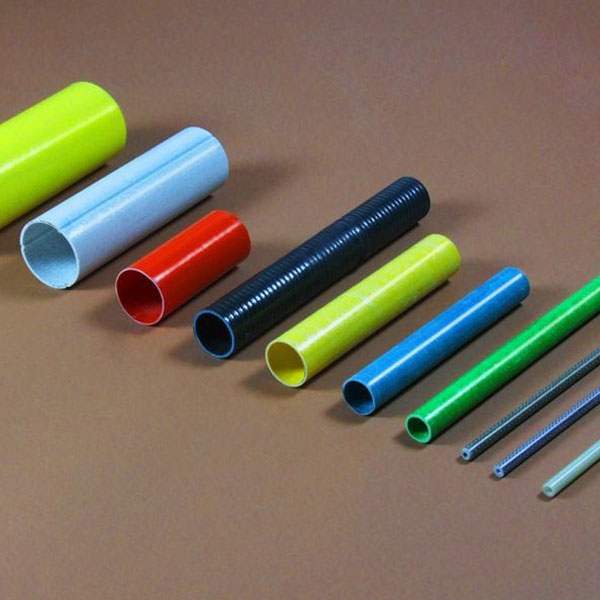

ท่อ FRP หรือท่อพลาสติกเสริมใยแก้ว เป็นโครงสร้างคอมโพสิตประสิทธิภาพสูงที่ผลิตจากเมทริกซ์โพลีเมอร์เสริมด้วยเส้นใย ซึ่งโดยทั่วไปจะเป็นใยแก้ว คาร์บอน หรืออะรามิด ท่อเหล่านี้ขึ้นชื่อเรื่องอัตราส่วนความแข็งแรงต่อน้ำหนักที่ยอดเยี่ยม ความต้านทานการกัดกร่อน และความทนทาน ทำให้เหมาะสำหรับการใช้งานในอุตสาหกรรมและเชิงพาณิชย์หลากหลายประเภท.

การผลิตท่อ FRP มักใช้เทคนิคต่างๆ เช่น การพันเส้นใย การดึงขึ้นรูป หรือการวางเส้นใยด้วยมือ การพันเส้นใยเป็นหนึ่งในวิธีการที่ได้รับความนิยมมากที่สุด โดยใช้เส้นใยต่อเนื่องพันรอบแกนหมุนในรูปแบบที่กำหนด แล้วจึงนำไปอบให้แข็งตัว กระบวนการนี้ช่วยให้สามารถควบคุมทิศทางของเส้นใยได้อย่างแม่นยำ ซึ่งช่วยเพิ่มคุณสมบัติทางกลของท่อ.

ข้อดีสำคัญประการหนึ่งของท่อ FRP คือความทนทานต่อปัจจัยด้านสิ่งแวดล้อม ต่างจากโลหะ FRP ไม่เป็นสนิมหรือผุกร่อน แม้จะสัมผัสกับสารเคมีรุนแรง รังสี UV หรือสภาพแวดล้อมทางทะเลที่มีความเค็มสูง ทำให้มีประโยชน์อย่างยิ่งในอุตสาหกรรมต่างๆ เช่น การแปรรูปทางเคมี การบำบัดน้ำเสีย และวิศวกรรมทางทะเล.

ในแง่ของสมรรถนะเชิงกล ท่อ FRP มีความแข็งแรงต่อแรงดึงและแรงอัดสูง ในขณะที่ยังคงมีน้ำหนักเบา คุณสมบัตินี้ช่วยลดน้ำหนักโดยรวมของโครงสร้างได้อย่างมาก และทำให้การติดตั้งและการขนส่งง่ายขึ้น นอกจากนี้ FRP ยังเป็นวัสดุที่ไม่นำไฟฟ้า ทำให้ท่อเหล่านี้เหมาะสำหรับงานที่ต้องการฉนวนไฟฟ้า เช่น รางสายเคเบิลหรือเสาไฟฟ้า.

ท่อ FRP ยังสามารถปรับแต่งได้ในแง่ของเส้นผ่านศูนย์กลาง ความหนาของผนัง ความยาว และองค์ประกอบของเส้นใย เพื่อให้ตรงตามความต้องการใช้งานเฉพาะ นอกจากนี้ อายุการใช้งานที่ยาวนานและความต้องการการบำรุงรักษาที่น้อยที่สุด ยังช่วยลดต้นทุนรวมในการเป็นเจ้าของในระยะยาวอีกด้วย.

ข้อมูลจำเพาะและพารามิเตอร์ทางเทคนิคของท่อ FRP

ท่อ FRP (พลาสติกเสริมใยแก้ว) มีหลากหลายสเปคขึ้นอยู่กับการใช้งาน กระบวนการผลิต และชนิดของเส้นใยเสริมแรงที่ใช้ ด้านล่างนี้คือภาพรวมทั่วไปของสเปคและพารามิเตอร์ทางเทคนิคที่สำคัญซึ่งมักเกี่ยวข้องกับท่อ FRP:

1. ขนาด

- เส้นผ่านศูนย์กลางภายนอก (OD): 10 มม. – 1000 มม. (สามารถปรับแต่งได้)

- ความหนาของผนัง: 1 มม. – 50 มม.

- ความยาว: มีความยาวมาตรฐานตั้งแต่ 1 เมตร ถึง 6 เมตร (สามารถสั่งทำความยาวพิเศษได้)

2. ส่วนประกอบของวัสดุ

- ประเภทเรซิน:

- โพลีเอสเตอร์ (อเนกประสงค์)

- ไวนิลเอสเทอร์ (ทนต่อสารเคมี)

- อีพ็อกซี่ (ความแข็งแรงสูง, งานโครงสร้าง)

- การเสริมแรงด้วยเส้นใย:

- อี-กลาส (ชนิดที่พบมากที่สุด)

- กระจก S (มีความแข็งแรงสูงกว่า)

- คาร์บอนไฟเบอร์ (มีความแข็งแรงสูงและน้ำหนักเบา)

- อะรามิด (ทนแรงกระแทก)

3. คุณสมบัติทางกล (ค่าทั่วไป; อาจแตกต่างกันไปตามเส้นใย/เรซินและทิศทาง)

- ความต้านแรงดึง: 200 – 1200 เมกะปาสคาล

- ความแข็งแรงต่อแรงอัด: 150 – 800 เมกะปาสคาล

- ความแข็งแรงดัดงอ: 250 – 1000 เมกะปาสคาล

- โมดูลัสความยืดหยุ่น: 10 – 45 GPa

- ความแข็งแรงของแรงกระแทก: สูง (โดยเฉพาะกับเส้นใยอะรามิด)

4. คุณสมบัติทางกายภาพ

- ความหนาแน่น: 1.5 – 2.0 กรัม/ซม³ (ขึ้นอยู่กับปริมาณเส้นใยและเรซิน)

- การนำความร้อน: 0.25 – 0.35 วัตต์/เมตร·เคลวิน

- สัมประสิทธิ์การขยายตัวทางความร้อน: 5 – 10 ×10⁻⁶ /°C

- ช่วงอุณหภูมิการทำงาน: -40°C ถึง +120°C (สามารถทนอุณหภูมิได้สูงกว่านี้หากใช้เรซินชนิดพิเศษ)

5. คุณสมบัติทางไฟฟ้า

- ความเป็นฉนวน: ≥ 10 kV/mm

- ความต้านทานพื้นผิว: ≥ 10¹² โอห์ม

- ไม่นำไฟฟ้า: เหมาะสำหรับงานด้านไฟฟ้าและคลื่นวิทยุ

6. ความทนทานต่อสภาพแวดล้อม

- ความต้านทานการกัดกร่อน: ทนทานต่อกรด ด่าง และน้ำทะเลได้ดีเยี่ยม

- ความต้านทานรังสียูวี: ด้วยสารยับยั้งรังสียูวีหรือสารเคลือบ

- การดูดซับความชื้น: < 1%

- การผุกร่อน: ทนทานสูงต่อสภาพแวดล้อมกลางแจ้ง

7. วิธีการผลิต

- การอัดขึ้นรูป: ความแม่นยำสูง ภาคตัดขวางสม่ำเสมอ

- การม้วนเส้นใย: การออกแบบตามสั่งที่มีความแข็งแรงสูง

- การหล่อแบบแรงเหวี่ยง: สำหรับท่อขนาดใหญ่หรือท่อผนังหนา

เหตุใดจึงเลือกเรา

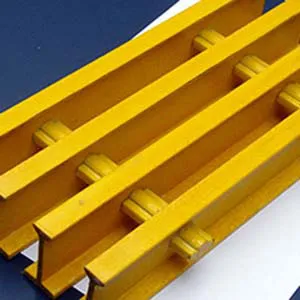

ความเชี่ยวชาญด้านการผลิตตะแกรง FRP

ด้วยประสบการณ์กว่า 20 ปี โรงงานของเราเชี่ยวชาญเฉพาะด้านการออกแบบ พัฒนา และผลิตตะแกรง FRP (พลาสติกเสริมใยแก้ว) ประสิทธิภาพสูง ความรู้เชิงลึกในอุตสาหกรรมของเราทำให้มั่นใจได้ว่าทุกผลิตภัณฑ์ตรงตามมาตรฐานอุตสาหกรรมที่เข้มงวดที่สุด.

เทคโนโลยีและอุปกรณ์ขั้นสูง

เราใช้เครื่องมือการผลิตที่ทันสมัยและเทคโนโลยีการขึ้นรูปที่แม่นยำเพื่อผลิตตะแกรงที่มีความแข็งแรง ทนทานต่อการกัดกร่อน และความแม่นยำของขนาดที่เหนือกว่า ความมุ่งมั่นของเราในการสร้างสรรค์นวัตกรรมหมายความว่าโครงการของคุณจะได้รับประโยชน์จากความก้าวหน้าล่าสุดในเทคโนโลยี FRP.

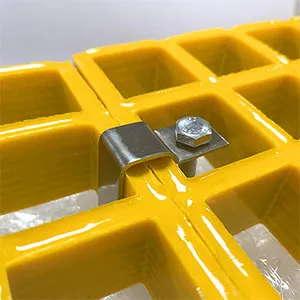

โซลูชันที่ปรับแต่งได้

เรานำเสนอการปรับแต่งอย่างครบวงจร ตั้งแต่ขนาดแผ่นและประเภทเรซิน ไปจนถึงการตกแต่งพื้นผิวและสี เพื่อตอบสนองความต้องการใช้งานเฉพาะของคุณ ไม่ว่าจะเป็นพื้นอุตสาหกรรม ขั้นบันได ฝาปิดร่องน้ำ หรือแท่นขุดเจาะทางทะเล.

การควบคุมคุณภาพที่เข้มงวด

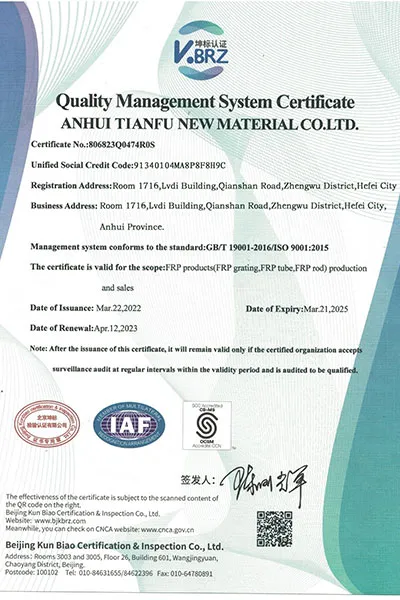

ผลิตภัณฑ์ทุกชิ้นผ่านกระบวนการตรวจสอบคุณภาพอย่างเข้มงวด รวมถึงการทดสอบการรับน้ำหนัก การตรวจสอบความหน่วงไฟ และการวิเคราะห์ความต้านทานการกัดกร่อน ระบบการจัดการคุณภาพที่ได้รับการรับรองมาตรฐาน ISO ของเราช่วยให้มั่นใจได้ถึงความเป็นเลิศอย่างสม่ำเสมอในทุกชุดการผลิต.

ราคาที่แข่งขันได้

เราเสนอราคาส่งตรงจากโรงงานโดยไม่ลดทอนคุณภาพ ด้วยกระบวนการผลิตที่มีประสิทธิภาพสูงสุดและความสามารถในการผลิตจำนวนมาก เราช่วยให้ลูกค้าประหยัดต้นทุนได้ในระดับขนาดใหญ่.

ระบบจัดส่งที่เชื่อถือได้และครอบคลุมทั่วโลก

เรามีสินค้ามาตรฐานในสต็อกจำนวนมาก และดำเนินงานระบบโลจิสติกส์ที่คล่องตัว ทำให้มั่นใจได้ว่าการจัดส่งจะรวดเร็วทั้งในประเทศและต่างประเทศ เราให้บริการลูกค้าในกว่า 15 ประเทศมาแล้วอย่างประสบความสำเร็จ.

สินค้าขายดี

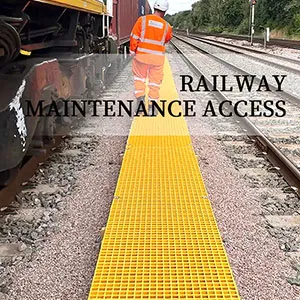

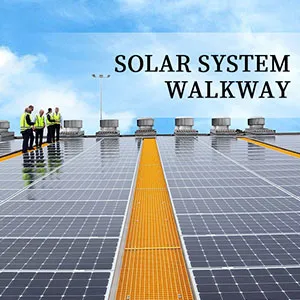

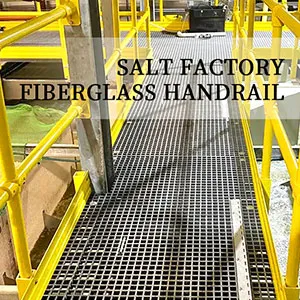

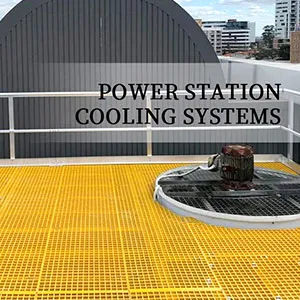

สถานการณ์การใช้งาน

เกี่ยวกับโรงงาน

เราเป็นผู้ผลิตตะแกรง FRP มืออาชีพที่มีประสบการณ์มากกว่า 20 ปี โรงงานขนาด 26,000 ตารางเมตรของเราได้รับการรับรองมาตรฐาน ISO9001 ให้บริการลูกค้าในกว่า 30 ประเทศด้วยความสามารถในการผลิตแบบ OEM/ODM เรานำเสนอโซลูชันที่ปรับแต่งได้และจัดส่งรวดเร็วทั่วโลก.

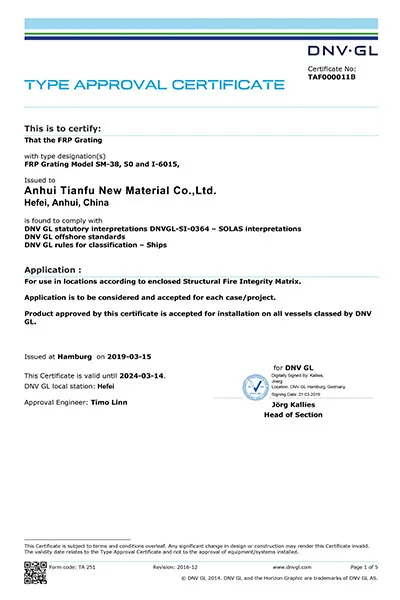

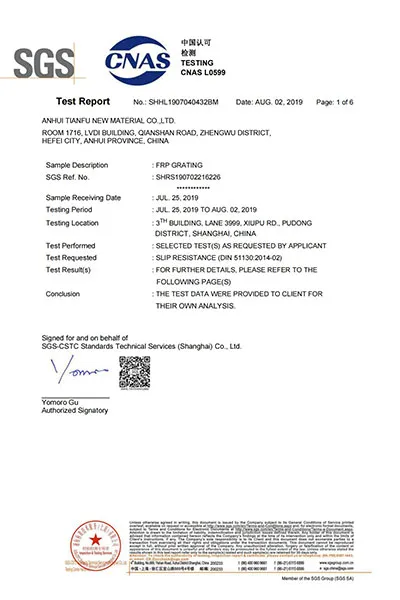

ตะแกรง FRP ของเราผลิตตามมาตรฐาน ISO 9001 และผ่านการทดสอบตามมาตรฐาน ASTM E84 (ระดับการทนไฟ Class 1), ASTM D638/D790 สำหรับสมรรถนะเชิงกล และเป็นไปตามมาตรฐาน BS 476 และ EN 13706 สามารถขอรับการทดสอบจากหน่วยงานภายนอก เช่น SGS และ TUV ได้ตามคำขอ.

นิทรรศการ

เจอีซี เวิลด์ 2023

เจอีซี เวิลด์ 2024

CAMX 2025

เซี่ยงไฮ้ 2025

ใบรับรอง

สินค้าอื่นๆ

ทัวร์ชมโรงงานเสมือนจริง (VR Factory Tour)

ท่อ FRP

แอปพลิเคชัน

วัสดุหุ้มผนังและฝ้าเพดานในห้องครัวเชิงพาณิชย์ ห้องน้ำ ห้องปลอดเชื้อ และห้องเย็น วัสดุบุและป้องกันถังและท่อส่งสารเคมี แผ่นฉนวนไฟฟ้า แผ่นหลังคาสำหรับอาคารอุตสาหกรรม แผ่นสำหรับงานทางทะเลและพื้นขนส่ง

ความแข็งแรงดึง :

200 – 1200 เมกะปาสคาล

ความแข็งแรงต่อแรงอัด :

150 – 800 เมกะปาสคาล

ความแข็งแรงดัดงอ :

250 – 1000 เมกะปาสคาล

โมดูลัสของความยืดหยุ่น :

10 – 45 GPa

ความแข็งแรงในการรับแรงกระแทก :

สูง (โดยเฉพาะกับเส้นใยอะรามิด)

คำถามที่พบบ่อย

ถาม :

ท่อ FRP ทำมาจากอะไร?

ตอบ :

ท่อ FRP ผลิตจากเมทริกซ์โพลีเมอร์ (โดยทั่วไปคือโพลีเอสเตอร์ ไวนิลเอสเตอร์ หรืออีพ็อกซีเรซิน) เสริมด้วยเส้นใยที่แข็งแรง เช่น ใยแก้ว คาร์บอน หรืออะรามิด การผสมผสานนี้ทำให้ได้วัสดุคอมโพสิตที่มีน้ำหนักเบาแต่แข็งแรง.

ถาม :

การใช้ท่อ FRP มีข้อดีอย่างไรเมื่อเทียบกับท่อโลหะหรือ PVC?

ตอบ :

ท่อ FRP มีอัตราส่วนความแข็งแรงต่อน้ำหนักสูง ทนทานต่อการกัดกร่อนได้ดีเยี่ยม เป็นฉนวนไฟฟ้า บำรุงรักษาง่าย และมีอายุการใช้งานยาวนาน แตกต่างจากโลหะตรงที่ไม่เป็นสนิมและไม่นำไฟฟ้า และมีความแข็งแรงและทนต่ออุณหภูมิได้ดีกว่า PVC.

ถาม :

ท่อ FRP นิยมใช้ในงานใดบ้าง?

ตอบ :

การใช้งานทั่วไป ได้แก่ โครงสร้างค้ำยัน ท่อร้อยสายเคเบิล ราวบันได บันได โครงสร้างทางทะเล เสาอากาศ ท่อส่ง และชิ้นส่วนโรงงานเคมี มีการใช้งานอย่างแพร่หลายในอุตสาหกรรมต่างๆ เช่น การก่อสร้าง การเดินเรือ ไฟฟ้า และการบำบัดน้ำเสีย.

ถาม :

ท่อ FRP สามารถทนต่อสภาพแวดล้อมกลางแจ้งและสภาพแวดล้อมที่รุนแรงได้หรือไม่?

ตอบ :

ใช่แล้ว ท่อ FRP ทนต่อรังสียูวี (หากเคลือบผิวอย่างเหมาะสม) ทนต่อสารเคมี และทนต่อความชื้น ทำให้เหมาะสำหรับใช้งานกลางแจ้ง ทางทะเล และสภาพแวดล้อมทางอุตสาหกรรมที่มีฤทธิ์กัดกร่อน.

ถาม :

ท่อ FRP สามารถปรับแต่งได้หรือไม่?

ตอบ :

แน่นอน ท่อ FRP สามารถผลิตได้ในขนาดเส้นผ่านศูนย์กลาง ความหนาของผนัง ความยาว สี และการจัดเรียงเส้นใยที่หลากหลาย เพื่อให้ตรงตามข้อกำหนดด้านกลไก ความร้อน หรือเคมีที่เฉพาะเจาะจง.

ถาม :

ท่อ FRP ติดตั้งอย่างไร?

ตอบ :

ท่อ FRP นั้นตัด เจาะ และประกอบได้ง่ายโดยใช้เครื่องมือมาตรฐาน สามารถเชื่อมต่อกันได้โดยใช้กาว ตัวยึดเชิงกล หรือข้อต่อ ขึ้นอยู่กับการใช้งาน.

สินค้าอื่นๆที่เกี่ยวข้อง