- Linear Density: The yarn has a linear density of 68 Tex, which is a measure of the mass per unit length. This Tex rating indicates a relatively lightweight and fine fiberglass yarn.

- Texturizing: The yarn has undergone a texturizing process, which involves applying mechanical, thermal, or chemical treatments to create a more irregular, bulky, and soft surface texture.

- Composition: Typically composed of continuous E-glass or S-glass fibers, which provide the core strength and thermal resistance properties.

- Yarn Structure: The texturized fiberglass yarn is available in various configurations, such as single-end or multi-filament, depending on the intended application.

Fiberglass yarn is electrical insulation materials ,electronic industrial fabrics,tubes and other industrial fabric raw materials. It”s widely used for circuit board,weaving all kinds of fabrics in the scope of reinforcement ,insulation,corrosion resistance,heat resistance and so on.

Product performance introduction

Fiberglass Yarn

Fiberglass yarn is a fiberglass twisting yarn.Its high strength, corrosion resistance, high temperature resistant, moisture absorption, good electrical insulating performance, used in weaving, casing, mine fuse wire and cable coating layer, the winding of electric machines and appliances insulating material, various machine weaving yarn and other industrial yarn.

68 Tex Texturised Fiberglass Yarn Description

68 Tex Texturised Fiberglass Yarn is a high-performance yarn manufactured from continuous filament fiberglass strands that have undergone a texturizing process. This process enhances the yarn’s flexibility and handling characteristics, providing improved texture and bulk while maintaining the inherent strength and durability of fiberglass.

68 Tex Texturized Fiberglass Yarn combines the inherent strength, thermal resistance, and chemical stability of fiberglass with the enhanced flexibility and drapability achieved through the texturizing process. This specialized yarn is well-suited for a variety of applications, from technical textiles and composites to thermal insulation and electrical components, where its unique properties can provide significant benefits.

Yarn Feature:

Yarn Advantages:

- High Durability: Exceptional resistance to abrasion and mechanical wear.

- Lightweight and Strong: Offers a strong yet lightweight solution for various applications.

- Fire Resistance: Inherently non-combustible, providing safety in high-risk environments.

- Moisture Resistance: Resistant to water and moisture, contributing to the longevity of products made with this yarn.

- Improved Handling and Conformability: The texturized surface provides a softer, more flexible yarn that is easier to work with during textile and composite manufacturing processes.

- Enhanced Thermal and Acoustic Insulation: The textured structure improves the insulation properties of the yarn, making it more effective in thermal and acoustic applications.

- Aesthetic Appeal: The textured surface can contribute to a more visually interesting and appealing appearance in certain textile and composite products.

Yarn Physical Properties:

- Diameter: Approximately 0.5 mm to 1.0 mm, providing a balance between strength and flexibility.

- Elongation: Offers low elongation, which provides stability and reduces the risk of sagging in applications.

- Thermal Resistance: Withstands temperatures up to 500°C (932°F), making it suitable for high-temperature environments.

- Tensile Strength: While the texturizing process can slightly reduce the overall tensile strength compared to untreated fiberglass yarn, it still maintains excellent load-bearing capabilities.

- Flexibility and Drapability: The texturizing process enhances the yarn’s flexibility and drapability, making it more suitable for textile applications that require a softer hand feel and improved conformability.

- Thermal Resistance: Retains the exceptional thermal resistance properties of fiberglass, capable of withstanding high temperatures without degradation.

- Chemical Resistance: Exhibits strong resistance to a wide range of chemicals, acids, and solvents, ensuring long-term durability.

- Electrical Insulation: Maintains the excellent electrical insulation properties inherent to fiberglass materials.

68 Tex E-glass Fiberglass Yarn Application

- Composites Manufacturing: Used as reinforcement in composite materials for automotive, aerospace, and construction industries.

- Heat-Resistant Fabrics: Ideal for applications requiring heat and flame resistance, such as protective clothing and blankets.

- Electrical Insulation: Commonly used in electrical applications where insulation and thermal stability are needed.

- Industrial Textiles: Suitable for technical fabrics such as conveyor belts, fireproof curtains, and insulation materials.

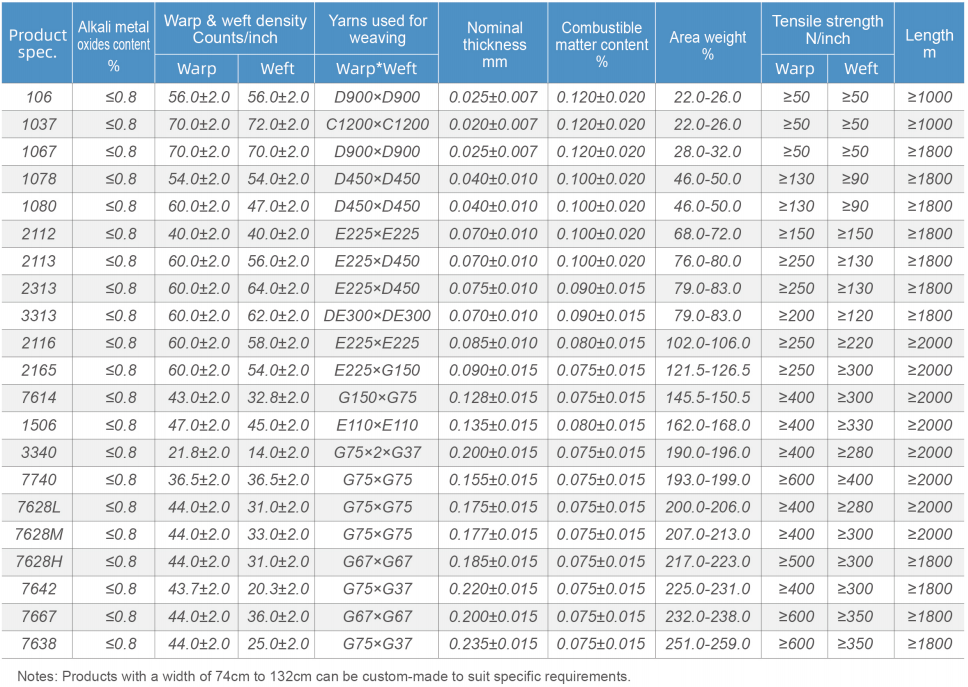

Technical Data

Packaging And Storage

- Packaging: Usually available in spools or cones, tailored to the specific needs of the customer.

- Storage Conditions: Should be stored in a dry environment away from direct sunlight to preserve integrity and performance.Store in a dry, cool environment, away from direct sunlight, to maintain its properties.

- Protective Gear: Always wear gloves, masks, and goggles to protect against skin irritation and fiber inhalation when handling this yarn.

The products are mainly packaged in cartons or metal frames. Unless otherwise specified, the products should be stored in a dry, cool and moisture-proof area. The room temperature should be maintained in an appropriate range,preferably between 15°C~35°C. lt is best if the product is used within 12 months after the production date. The products should be kept in their original packaging prior to use.

To ensure safety and avoid damage to the products, the pallets should be stacked no more than two layers high When the pallets are stacked in 2 layers, special care should be taken to correctly and smoothly move the upper pallet.

68 Tex Texturised Fiberglass Yarn

Series :

Proxy Products >application

Woven Fiberglass mesh (general yarn for warp, roving for weft) Weaving various electronic cloth

Brand name :

TFcomposite

Product name :

68Tex texturised fiberglass yarn

Material :

Fiberglass

Fiberglass Yarn :

fiberglass cloth

FAQ

Q :

What's the MOQ?

A :

Usually 1 Ton

Q :

What's your delivery time for production?

A :

If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days !

Other related products