Introducción al rendimiento del producto

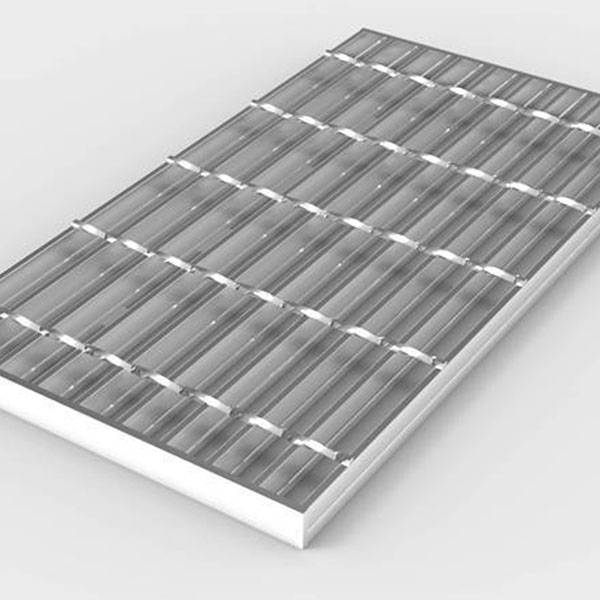

La rejilla de acero de barras en I es un tipo especial de rejilla de acero que se caracteriza por sus barras portantes en forma de I. Este diseño único ofrece una solución ligera pero robusta para diversas aplicaciones industriales, comerciales y arquitectónicas. Gracias a su relación resistencia-peso, la rejilla de acero de barras en I es la opción preferida para aplicaciones donde la reducción del peso del material es una prioridad sin comprometer la capacidad de carga.

1. Especificaciones de la rejilla de acero de barra en I

Composición del material

-

Acero carbono:Proporciona resistencia y durabilidad excepcionales.

-

Acero inoxidable:Ofrece resistencia a la corrosión, ideal para entornos hostiles.

-

Acero galvanizado:Mejora la longevidad y previene la formación de óxido.

-

Aluminio:Ligero y resistente a la corrosión, utilizado en aplicaciones marinas y arquitectónicas.

Opciones de tratamiento de superficies

-

Galvanización por inmersión en caliente:Más común para protección contra la corrosión a largo plazo.

-

Recubrimiento en polvo:Agrega valor estético y resistencia adicional a la corrosión.

-

Acabado de molino: Adecuado para aplicaciones en interiores con exposición mínima a elementos corrosivos.

-

Recubrimiento de pintura:Proporciona mayor durabilidad y personalización del color.

Capacidad de carga

-

Diseñado para soportar cargas pesadas con una desviación mínima.

-

Capacidades de carga personalizadas disponibles según el tamaño y el espaciado de las barras de soporte.

2. Modelos y tipos

Basado en el perfil de la barra de apoyo

-

Rejilla de barras estándar I:Ofrece una relación resistencia-peso equilibrada.

-

Rejilla de barra dentada en I:Proporciona una mayor resistencia al deslizamiento, ideal para entornos húmedos o aceitosos.

-

Rejilla de barra en I de alta resistencia:Diseñado para aplicaciones industriales de alta carga.

Basado en el método de fabricación

-

Rejilla de barra en I soldada:Ofrece alta resistencia estructural y rigidez.

-

Rejilla de barra en I con cierre a presión:Proporciona una apariencia uniforme y una superficie lisa.

-

Rejilla de barra en I con bloqueo por estampación:Garantiza tolerancias estrictas y una excelente distribución de la carga.

3. Dimensiones

Dimensiones de la barra de apoyo

-

Grosor: Normalmente varía entre 5 mm a 10 mm.

-

Altura: Las alturas comunes incluyen 25 mm, 30 mm, 40 mm y 50 mm.

-

Ancho: Normalmente entre 20 mm y 100 mm.

Dimensiones de la barra transversal

-

Diámetro: Generalmente entre 5 mm y 8 mm para barras redondas.

-

Barras planas: generalmente 3 mm a 6 mm grueso.

Configuraciones de espaciado

-

30 mm x 100 mm:Norma para pasos peatonales.

-

40 mm x 100 mm:Ideal para aplicaciones de trabajo ligero.

-

30 mm x 50 mm:Proporciona mayor capacidad de carga.

Tamaños de los paneles

-

Panel estándar: 1.000 mm x 6.000 mm.

-

Tamaños personalizados: disponibles a pedido para adaptarse a las necesidades específicas del proyecto.

4. Consideraciones de diseño

-

Requisitos de carga estructural:Elija el espesor y el espaciado de las barras adecuados para garantizar que la rejilla pueda soportar las cargas necesarias.

-

Factores ambientales:Para ambientes corrosivos, seleccione acero inoxidable o acero galvanizado.

-

Resistencia al deslizamiento:La rejilla dentada en forma de I se recomienda para áreas propensas a la humedad.

-

Requisitos estéticos:El recubrimiento en polvo se puede aplicar en varios colores para complementar los diseños arquitectónicos.

5. Aplicaciones de la rejilla de acero en forma de I

-

Plataformas industriales:Ideal para zonas con maquinaria pesada por su alta capacidad de carga.

-

Pasarelas y pasarelas:Ligero y fácil de instalar.

-

Cubiertas de drenaje:Permite un drenaje eficiente del agua manteniendo la resistencia.

-

Fachadas arquitectónicas:Proporciona una apariencia elegante y moderna.

-

Instalaciones marinas y offshore:Resistente a la corrosión del agua salada con elecciones de materiales apropiadas.

Conclusión

La rejilla de acero en I es una opción versátil y confiable para diversas aplicaciones estructurales. Su alta relación resistencia-peso, resistencia a la corrosión y dimensiones personalizables la convierten en una opción práctica tanto para proyectos industriales como comerciales. Al seleccionar el material, el tratamiento superficial y la configuración de las barras adecuados, los usuarios pueden garantizar un rendimiento óptimo y una larga vida útil en sus aplicaciones específicas.

Rejilla de acero de barra I

Serie :

Productos proxy >solicitud

Plataformas industriales: Ideales para áreas con maquinaria pesada gracias a su alta capacidad de carga. Pasarelas y pasarelas: Ligeras y fáciles de instalar. Cubiertas de drenaje: Permiten un drenaje eficiente del agua, manteniendo su resistencia. Fachadas arquitectónicas: Ofrecen una apariencia elegante y moderna. Instalaciones marinas y offshore: Resistentes a la corrosión por agua salada gracias a la elección de materiales adecuados.

Preguntas más frecuentes

Otros productos relacionados