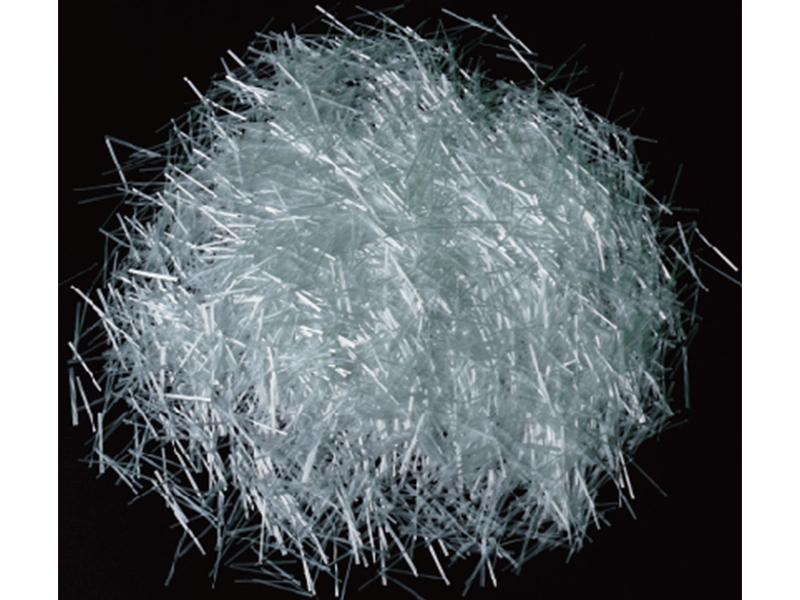

The alkali-free glass fiber composite untwisted roving yarn is made of multiple glass fiber composite yarn, divided into hard composite yarn and soft composite yarn.

Product performance introduction

Fiberglass Assembled Roving 310T-E6 Description

Assembled Roving 310T-E6 is coated with a silane-based sizing compatible withepoxy resin and designed for pultrusion process.Based on E6 formulation, 310T is suitable for use in insulation rods, and insulation stanchions, and is widely used in power generation, transmission,and distribution systems.

Fiberglass Assembled Roving 310T-E6 is an essential material in the composites industry, known for its strength, lightweight nature, and resistance to environmental factors. Its specialized features make it suitable for a wide range of demanding applications.

Features

- High Tensile Strength: Ideal for structural applications where durability is essential.

- Thermal Resistance: Can withstand high temperatures, making it useful in environments where thermal stability is required.

- Corrosion Resistance: Excellent resistance to chemicals and moisture, suitable for marine, industrial, and automotive applications.

- Lightweight: Despite its strength, it remains lightweight, making it advantageous for applications where weight reduction is critical.

Applications

- High Tensile Strength: Ideal for structural applications where durability is essential.

- Thermal Resistance: Can withstand high temperatures, making it useful in environments where thermal stability is required.

- Corrosion Resistance: Excellent resistance to chemicals and moisture, suitable for marine, industrial, and automotive applications.

- Lightweight: Despite its strength, it remains lightweight, making it advantageous for applications where weight reduction is critical.

SPECIFICATIONS

- Type of Glass:E6-Glass (E6)

- Type of Fiberglass:Assembled Roving (R)

- Standard Linear Mass Densities:2400, 4800, 9600 grams permetre (Tex)

- Filament Diameter:16 microns

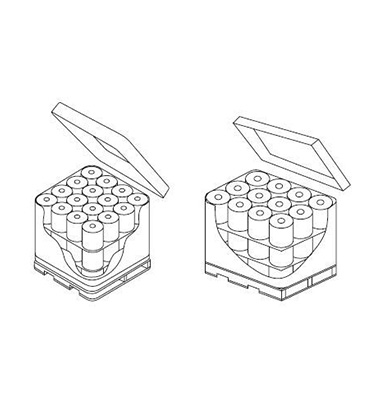

Package:Doffs can be packed on pallets or in small cardboard boxes.

Fiberglass Direct Roving 310T-E6

| Doff | 270 | 310 |

| Doff outside diameter | 270 mm (10.6 in) | 310 mm (12.2 in) |

| Doff inside diameter | 100 mm (4 in) | 100 mm (4 in) |

| Doff height | 260 mm (10 in) | 260 mm (10 in) |

| Doff weight | 17 kg (37.4 lb) | 22 kg (50.7 lb) |

| Pallet | ||||

| Number of layers per pallet | 3 | 4 | 3 | 4 |

| Number of doffs per layer | 16 | 16 | 12 | 12 |

| Number of doffs per pallet | 48 | 64 | 36 | 48 |

| Net weight | 816 (1797.3 lb) | 1088 kg (2396.5 lb) | 828 kg (1825 lb) | 1104 kg (2433.9 lb) |

| Length | 1120 mm (44 in) | 1120 mm (44 in) | 1270 mm (50 in) | 1270 mm (50 in) |

| Width | 1120 mm (44 in) | 1120 mm (44 in) | 960 mm (37.8 in) | 960 mm (37.8 in) |

| Height | 940 mm (37 in) | 1180 mm (46.5 in) | 940 mm (37 in) | 1180 mm (46.5 in) |

Fiberglass Assembled Roving 310T-E6

Series :

Proxy Products >application

Insulation rods Insulation stanchions Power generation, transmission and distribution systems

Brand name :

TFcomposite

Product name :

Fiberglass Assembled Roving 310T-E6

Material :

Fiberglass

FAQ

Q :

What's the MOQ?

A :

Usually 1 Ton

Q :

Package & Shipping.

A :

Normal package:carton(Incuded in the unite price) Special Packge: need to charge according the actual situation. Normal shipping :your nominated Freight forwarding.

Q :

What's your delivery time for production?

A :

If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days

Other related products