Assembled roving for spray up is coated with a silane based sizing, compatible with unsaturated polyester, vinyl ester and polyurethane resins.It is used to manufacture boats, yachts, sanitary ware, swimming pool and automotive parts and also pipe by centrifugal casting process.

Product performance introduction

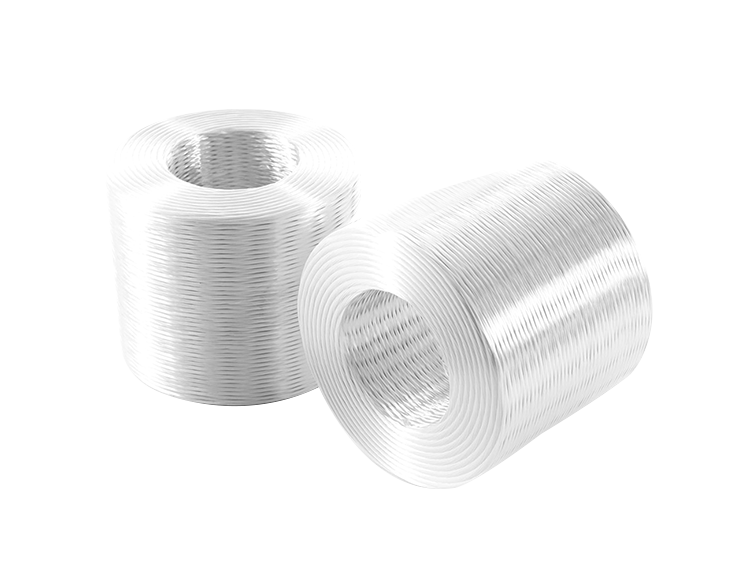

Fiberglass Assembled Roving Description:

Fiberglass Assembled Roving is a type of fiberglass product that combines multiple strands of fiberglass into a single, larger strand. This product is made by combining multiple fiberglass strands, or “fibers”, into a single strand, or “roving”, through a process called “assembling”.

Fiberglass Assembled Roving 778 Description:

Fiberglass Assembled Roving 778 is a high-quality product that combines multiple strands of fiberglass into a single, larger strand. This product is made by combining multiple fiberglass strands, or “fibers”, into a single strand, or “roving”, through a process called “assembling”.

778 Fiberglass Assembled Roving Properties:

Physical Properties:

- Fiber Diameter: 13-15 microns

- Strand Count: 240-260 strands per roving

- Roving Weight: 200-250 grams per meter

- Linear Density: 2.5-3.0 g/m

- Twist: 2-4 turns per meter

Mechanical Properties:

- Tensile Strength: 15,000-20,000 psi (103-137 MPa)

- Elongation at Break: 3-5%

- Modulus of Elasticity: 7-9 million psi (48-62 GPa)

- Bending Stiffness: 0.5-1.5 x 10^3 N/mm^2

Thermal Properties:

- Melting Point: 820-850°C (1510-1562°F)

- Glass Transition Temperature (Tg): 550-600°C (1022-1112°F)

- Thermal Expansion Coefficient: 9-12 x 10^-6 K^-1

Electrical Properties:

- Dielectric Strength: 200-400 V/mil (8-16 kV/mm)

- Dielectric Constant: 3.5-4.5

- Volume Resistivity: 10^10-10^12 ohm-cm

Chemical Properties:

- pH Level: 7-9

- Moisture Content: <0.5%

- Solubility: Insoluble in water, organic solvents, and most acids and bases

778 Fiberglass Assembled Roving Feature:

- High-quality fiberglass strands

- Improved strength and durability

- Available in a variety of sizes and configurations

- Can be used in a variety of applications, including textile production, composite materials, insulation, and more

Principle of manufacturing:

Step 1: Fiberglass Strand Production

- The manufacturing process begins with the production of individual fiberglass strands through a process called spinning.

- The raw material used for spinning is a type of glass wool that is made from a mixture of sand, soda, and limestone.

- The glass wool is heated to a high temperature until it melts and forms a long, thin strand.

- The strand is then wound onto a spool to form a single, individual strand.

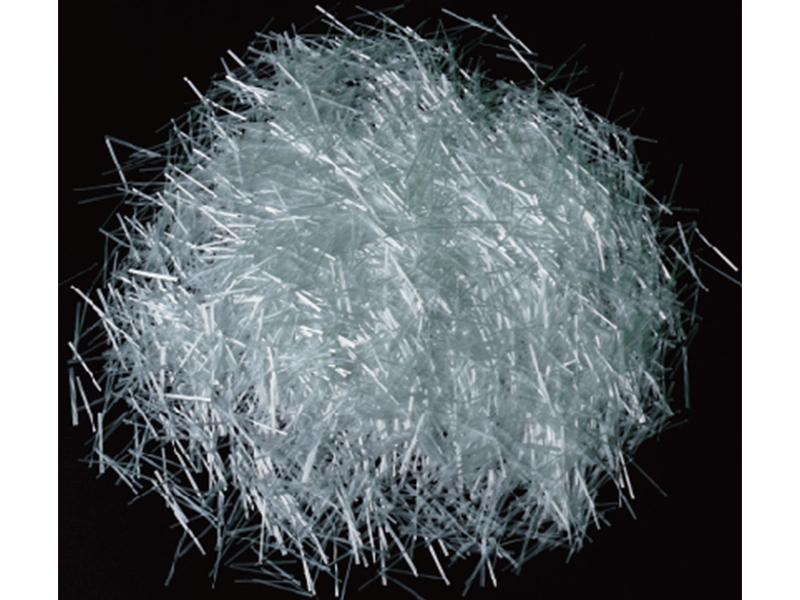

Step 2: Fiber Drawing and Cutting

- The individual fiberglass strands are then subjected to a process called fiber drawing, which involves stretching and drawing out the strand to the desired length and thickness.

- The strand is then cut to the desired length using a cutting die.

- The cutting process is critical to ensure that the strands are of uniform length and thickness.

Step 3: Assembly of Fiberglass Strands

- The individual fiberglass strands are then assembled into a single, larger strand through a process called assembling.

- The assembling process involves twisting the individual strands together to form a single roving.

- The twist is critical to ensure that the strands are securely held together and that the roving has the desired properties.

Step 4: Roving Winding

- The assembled roving is then wound onto a spool or cone to form the final product.

- The winding process involves winding the roving in a specific pattern to ensure that the strands are evenly spaced and that the roving has the desired texture.

Step 5: Quality Control and Testing

- The final product is then subjected to quality control and testing to ensure that it meets the required standards.

- The testing process includes measurements of the roving’s diameter, tensile strength, and elongation at break.

778 Fiberglass Assembled Roving Application:

- Fiberglass Assembled Roving 778 is commonly used in a variety of applications, including:

- Textile production

- Composite materials

- Insulation

- Reinforced plastics

- And more

Technical Data:

Dimensions and Tolerances:

- Diameter Tolerance: ±5%

- Length Tolerance: ±2%

- Twist Tolerance: ±10%

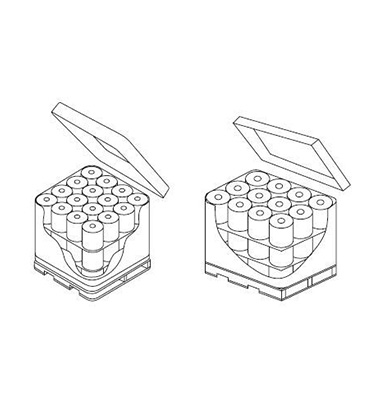

Packaging And Storage:

| Doff | 270 | 310 |

| Doff outside diameter | 270 mm (10 in) | 310 mm (12.2 in) |

| Doff inside diameter | 160 mm (6.3 in) | 160 mm (6.3 in) |

| Doff height | 260 mm (10 in) | 260 mm (10 in) |

| Doff weight | 15.6 kg (34.4 lb) | 22 kg (48.5 lb) |

| Pallet | ||||

| Number of layers per pallet | 3 | 4 | 3 | 4 |

| Number of doffs per layer | 16 | 16 | 12 | 12 |

| Number of doffs per pallet | 48 | 64 | 36 | 48 |

| Net weight | 750 (1653.4 lb) | 1000 kg (2204.6 lb) | 792 kg (1746 lb) | 1056 kg (2328 lb) |

| Length | 1120 mm (44 in) | 1120 mm (44 in) | 1270 mm (50 in) | 1270 mm (50 in) |

| Width | 1120 mm (44 in) | 1120 mm (44 in) | 960 mm (37.8 in) | 960 mm (37.8 in) |

| Height | 940 mm (37 in) | 1180 mm (46.5 in) | 940 mm (37 in) | 1180 mm (46.5 in) |

Strong Market Presence:

As trusted fiberglass yarn suppliers, we offer competitive wholesale prices and ensure reliable supply across various sectors. Whether you need robust weaving solutions, durable casing materials, or efficient electrical insulation, our E-Glass Fiberglass Yarn meets your requirements with excellence. Count on our commitment to quality and innovation to enhance your manufacturing processes.

Contact us today to learn more about our E-Glass Fiberglass Yarn offerings and how we can support your specific needs. Elevate your industrial operations with our premium fiberglass yarn solutions!

After-sales service:

Fast delivery, affordable prices, enthusiastic full service, contact us immediately.

Resin Compatibility: Epoxy (EP) Unsaturated polyester Vinyl ester

USES:Boats/yachts Chemical corrosion resistance applications

Fiberglass Assembled Roving 778

Series :

Proxy Products >application

Boats/yachts • Chemical corrosion resistance applications

Brand name :

TFcomposite

Product name :

Fiberglass Assembled Roving-778

Material :

Fiberglass

FAQ

Q :

What's the MOQ?

A :

Usually 1 Ton

Q :

Package & Shipping.

A :

Normal package:carton(Incuded in the unite price) Special Packge: need to charge according the actual situation. Normal shipping :your nominated Freight forwarding.

Q :

What's your delivery time for production?

A :

If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days

Other related products