Fiberglass products for continuous profiles

We are a reputable supplier of glass fiber raw materials including direct roving, chopped strands, mat, and yarn. We maintain ample stock and offer competitive prices. Feel free to reach out to us through our online inquiry form, accessible 24/7.

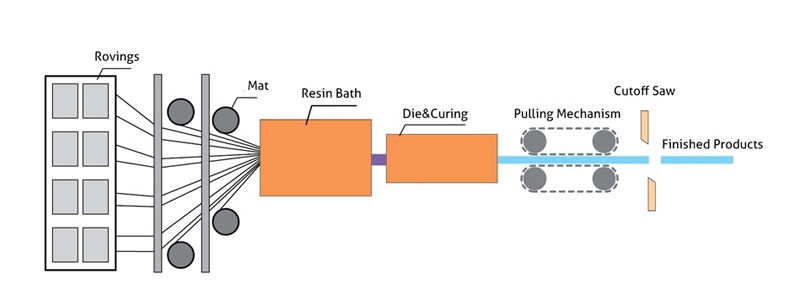

Pultrusion Process

The rovings, mats or other fabrics are pulled through a resin impregnation bath and then into a heated die using a continous pulling device. The final products are formed under high temperature and high pressure conditions.

Rovings for Pultrusion

Rovings for Pultrusion are compatible with UP, EP , VE and PF resins and widely used in building & construction, telecommunication and insulation industries.

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

Assembled roving, low filament diameter, good compatibility with resin, fast and complete wet-out, excellent mechanical properties

Pultrusion profiles for outdoor sports equipment -

Assembled roving, good compatibility with resin, fast and complete wet-out, excellent electrical insulation and mechanical properties

Electrical insulation rods -

good compatibility with resin, fast and complete penetration

Pultrusion profiles -

good compatibility with resin, fast and complete penetration

Pultrusion profiles -

Direct roving, compatible with matrix resin, high tensile strength of composite products

Optic cables -

Direct roving, low fuzz, good compatibility with polyurethane resin, good wet-out, excellent mechanical properties

Various pultrusion profiles, telegraph pole, etc -

Direct roving, compatible with matrix resin, fast wet-out, excellent mechanical properties of composite products

Various sectional bars and optic cables -

Direct roving, soft strand, good compatibility with resin, fast wet-out, excellent mechanical properties

Various sectional bars

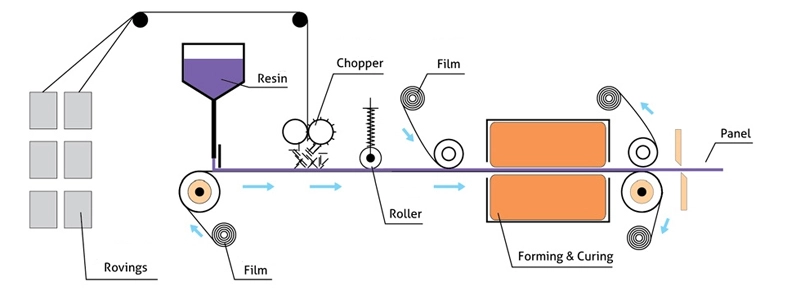

Continuous Panel Molding Process

A resin mix is uniformly deposited in a controlled amount onto a moving film at aconstant speed. The thickness of the resin is controlled by the draw-knife. Fiberglass roving is chopped and

uniformly distributed onto the resin. Then a top film is applied forming a sandwich structure. The wet assembly travels through a curing oven to form the composite panel.

Assembled Panel Rovings

Assembled Panel Rovings are coated with a silane-based sizing and compatible with UP and acrylic resins. They can fast wet-out in resin and deliver excellent dispersion after chopping.

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

Low static, fast wet-out, no white fibers

General purpose transparent FRP panels -

Extremely fast wet-out, no white fibers, superior transparency

High transparency FRP panels -

Low static, moderate wet-out, excellent dispersion after chopping under low tension

Semitransparent and opaque FRP panels

Powder Chopped Strand Mats

Powder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time may be available upon request.