Fiberglass products for open molding

We are a reputable supplier of glass fiber raw materials including direct roving, chopped strands, mat, and yarn. We maintain ample stock and offer competitive prices. Feel free to reach out to us through our online inquiry form, accessible 24/7.

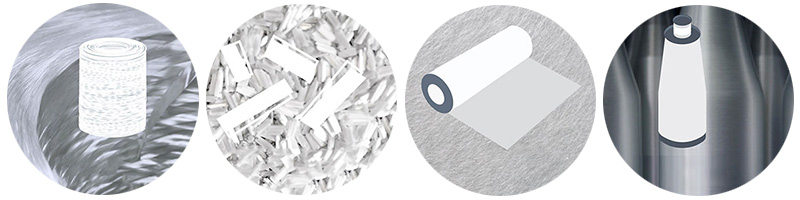

Spray-up Process

A mould is sprayed with a mixture of catalyzed resin and chopped fiberglass roving (fiberglass cut to specific length using a chopper gun). Then the glass-resin mixture is well compacted, usually manually,for complete impregnation and deairing.After curing the finished composite part is de-molded.

Assembled Rovings for Spray-up

Assembled Rovings for Spray-up are compatible with UP, VE and PU resins. They deliver properties of low static, excellent dispersion and good wet-out in resins.

-

Product CodeProduct FeaturesTypical ApplicationData Download

-

Good runnability for spraying operation, larger dispersion area in spraying, slower wet-out, less slide on vertical surfaces, suitable for production of large parts

Swimming pools, storage tanks, boats & yachts

-

Good runnability for spraying operation, moderate wet-out speed, easy roll-out, easy removal of bubbles,no spring back in sharp angles, excellent mechanical properties and hydrolytic resistance in parts, suitable for high-speed spray-up process with robots

Sanitary ware, FRP hulls, auto parts, chemical storage tanks

-

Good runnability for spraying operation, moderate wet-out speed, easy roll-out, easy removal of bubbles,no spring back in sharp angles, excellent mechanical properties and hydrolytic resistance in parts, suitable for high-speed spray-up process with robots

Sanitary ware, FRP hulls, auto parts, chemical storage tanks

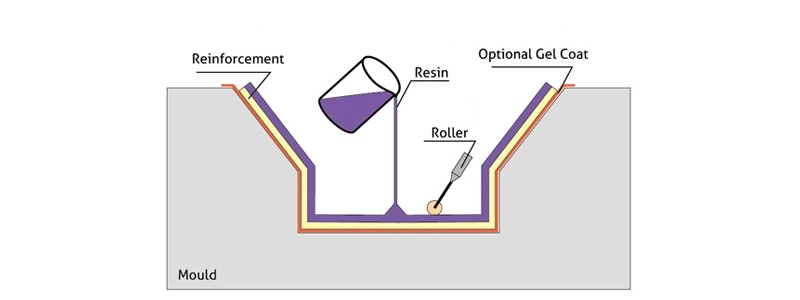

Hand Lay-up Process

The reinforcement, in form of fiberglass strands, mat or woven roving, is first laid into a mold which has been coated with a release agent and a gel coat. Then a resin mix is applied by hand using a brush or spray gun. A roller is then used to ensure uniform impregnation, complete glass wet-out, and removal of any trapped air bubbles. This operation is repeated until the desired thickness of the structure is obtained. After curing at room temperature or under heating conditions, the finished parts are formed.

Woven Rovings

Woven Rovings are compatible with UP, VE, EP and PF resins. Woven Rovings are available with a width range of 50mm~3,000mm and a weight range of 260g/m² ~1,600 g/m² . Other specifications are also available on customer request.

Emulsion Chopped Strand Mats

Emulsion Chopped Strand Mats are made of randomly distributed chopped strands held together by an emulsion binder. They are compatible with UP and VE resins. The roll width ranges from 200mm to 3,120mm. Special requirements may be available upon request.

-

Product CodeProduct FeaturesData Download

-

High tensile strength, allowing for use in hand lay-up process to produce large-area parts, no airborne fiber when operating, good wet-through and fast wet-out in resins, rapid air lease, high mechanical strength, superior acid corrosion resistance

-

Rapid air lease reducing rolling out times, low resin consumption

-

Good moldability, good wet-through and fast wet-out in resins, rapid air lease reducing rolling out times and increasing productivity, low resin consumption, high mechanical strength of composite products, superior acid corrosion resistance

Powder Chopped Strand Mats

Powder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time can be available upon request.

-

Product CodeTypical ApplicationData Download

-

High tensile strength, suitable for use in hand lay-up process to produce large-area parts, good wet-through and fast wet-out in resins, rapid air lease, high mechanical strength

-

Soft mat, ease of manual tearing apart, good conformability, good wet through and fast wet-out in resins, rapid air release reducing rolling out times and increasing productivity, low resin consumption, high mechanical strength of composite products, superior acid corrosion resistance