Le Garde-corps pour passerelles d'entretien solaire - Série 2000 Ces systèmes de sécurité et d'accès sont spécialement conçus pour les centrales solaires photovoltaïques et les installations en toiture. Ils offrent une plateforme de circulation non invasive, sécurisée et modulaire pour le personnel de maintenance. Leur conception légère et robuste garantit une durabilité à long terme, quelles que soient les conditions climatiques, sans compromettre les performances des panneaux ni l'intégrité de la toiture.

Présentation des performances du produit

Fiche technique :

| Fonctionnalité | spécification |

|---|---|

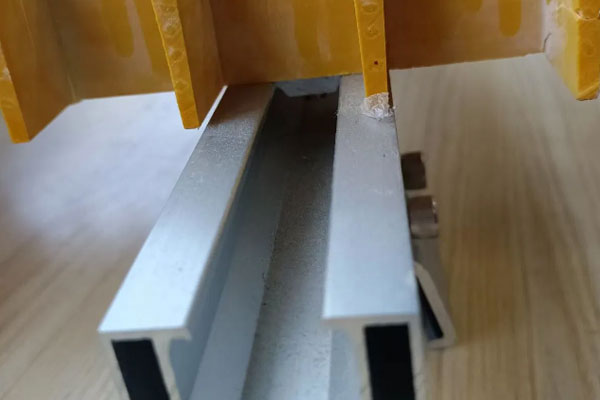

| Modèle | Rail de passerelle solaire – Série 2000 |

| Matériel | Alliage d'aluminium de qualité marine / Acier galvanisé à chaud / PRV (options) |

| Finition de surface | antidérapant dentelé / poncé / nervuré |

| Dimensions (standard) | Longueur : 3000 mm (personnalisable) Largeur : 600 mm Hauteur : 40 mm |

| Lester | ~8-12 kg par mètre (selon le matériau) |

| Capacité de charge | charge uniformément répartie ≥ 2,5 kN/m² |

| Type de fixation | Fixation par pince / sans pénétration pour toiture ou fixation directe par boulonnage pour installations au sol |

| Compatibilité | Compatible avec la plupart des systèmes de montage solaire à rails inclinables |

| Résistance aux UV | Oui (Matériaux stabilisés aux UV pour une utilisation en extérieur) |

| Résistance à la corrosion | Élevé (idéal pour les environnements côtiers ou désertiques) |

| Options de couleur | Jaune, gris, noir (standard) ; personnalisation sur demande |

| Accessoires en option | Garde-corps, plinthes, planches de rive, connecteurs de passerelle |

| Certifications | Conforme aux normes ISO 9001, CE et OSHA |

Applications:

-

Centrales solaires au sol et sur les toits

-

Systèmes photovoltaïques commerciaux et industriels

-

installations solaires sur toit plat

-

Parcs solaires à grande échelle

Principaux avantages :

-

SécuritéSurface antidérapante et barres de sécurité en option pour une sécurité accrue des travailleurs.

-

DurabilitéConçu pour résister à une exposition extrême aux UV, à la pluie, à la neige et au sable.

-

Facilité d'installationSa conception modulaire et légère réduit le temps de main-d'œuvre et d'installation.

-

Écologique: Matériaux recyclables 100% nécessitant peu d'entretien.

garde-corps de passerelle pour l'entretien des panneaux solaires

Série :

équipement de soutien >application

Plateformes et passerelles industrielles, couvertures de tranchées de drainage, sols de tours de refroidissement, installations offshore, façades architecturales, usines agroalimentaires

Marque :

TFcomposite

Nom du produit :

Machines à grilles moulées

FAQ

Q :

En quoi un caillebotis moulé diffère-t-il d'un caillebotis pultrudé ?

UN :

Le caillebotis moulé est fabriqué en coulant de la résine sur des nattes de fibre de verre dans un moule, ce qui lui confère une résistance bidirectionnelle. Le caillebotis pultrudé est fabriqué en étirant des brins continus de fibre de verre à travers un bain de résine et une filière chauffée, offrant ainsi une résistance longitudinale supérieure.

Q :

Quel type de presse est utilisé pour la production de grilles moulées ?

UN :

On utilise le plus souvent une presse à compression hydraulique à plateaux chauffants. Sa capacité varie de 500 à 1 500 tonnes, selon la taille et l’épaisseur de la grille.

Q :

Quels matériaux la machine peut-elle traiter ?

UN :

La machine est compatible avec : la fibre de verre (verre E ou verre S), les résines (polyester, vinylester, époxy, phénolique) et les additifs tels que les inhibiteurs UV, les pigments et les retardateurs de flamme.

Q :

Comment conçoit-on les moules pour des grilles de différentes tailles ?

UN :

Les moules sont fabriqués sur mesure en fonction des exigences suivantes : motifs de maille (carré, rectangulaire), épaisseur du panneau (par exemple, 25 mm, 38 mm, 50 mm), type de surface de la grille (concave, granuleuse, lisse).

Q :

Quel est le temps de cycle typique pour un panneau de grille moulé ?

UN :

Le cycle complet, de la mise en place au démoulage, prend généralement de 30 à 90 minutes, selon la taille du panneau, le type de résine et le système de durcissement.

Autres produits connexes