Isophthalic Unsaturated Polyester Resin (commonly abbreviated as isophthalic UPR) is a high-performance thermosetting resin widely used in the production of plastiques renforcés de fibres de verre (PRFV). Known for its excellent chemical resistance, enhanced mechanical properties, et superior thermal stability, it represents a significant upgrade from general-purpose o-phthalic resins. This document provides a comprehensive overview of isophthalic resin, including its propriétés, applications, processing techniques, and a detailed Fiche technique (FT).

Présentation des performances du produit

Isophthalic Unsaturated Polyester Resin (commonly abbreviated as isophthalic UPR) is a high-performance thermosetting resin widely used in the production of plastiques renforcés de fibres de verre (PRFV). Known for its excellent chemical resistance, enhanced mechanical properties, et superior thermal stability, it represents a significant upgrade from general-purpose o-phthalic resins. This document provides a comprehensive overview of isophthalic resin, including its propriétés, applications, processing techniques, and a detailed Fiche technique (FT).

2. What is Isophthalic Unsaturated Polyester Resin?

Isophthalic resin is a type of résine polyester insaturée synthesized by the condensation polymerization de isophthalic acid (IPA) or its anhydride, with glycols such as propylene glycol or diethylene glycol, and maleic anhydride. The unsaturated double bonds in the molecular chain make it curable by free radical polymerization, typically through initiators such as MEKP (methyl ethyl ketone peroxide).

This resin features a linear structure with pendant vinyl groups, making it compatible with cross-linking agents like styrene monomer. Compared with o-phthalic resin, isophthalic UPR offers higher resistance to chemicals, increased durability, et greater tensile strength.

3. Principales caractéristiques et avantages

-

✅ Superior Chemical Resistance

Suitable for applications involving acids, alkalis, and moderate solvents. -

✅ Haute résistance mécanique

Enhanced flexural, tensile, and impact strength make it ideal for load-bearing FRP components. -

✅ Excellent Thermal Stability

Capable of withstanding higher service temperatures (up to 120°C depending on formulation). -

✅ Improved Weatherability

Withstands UV exposure, water ingress, and thermal cycling better than standard resins. -

✅ Good Adhesion to Reinforcements

Works well with glass fiber, carbon fiber, and other synthetic reinforcements. -

✅ Longer Service Life

Durable in demanding environments such as marine, industrial, and outdoor applications.

4. Common Applications

Thanks to its enhanced performance profile, isophthalic UPR is used in many demanding structural and corrosion-resistant FRP products:

✔️ Industrial and Chemical Equipment

-

Tanks

-

Scrubbers

-

Pipes

-

Ducts

-

Fume hoods

✔️ Marine et Offshore

-

Boat hulls

-

Decks

-

panneaux marins

-

Jet ski and kayak components

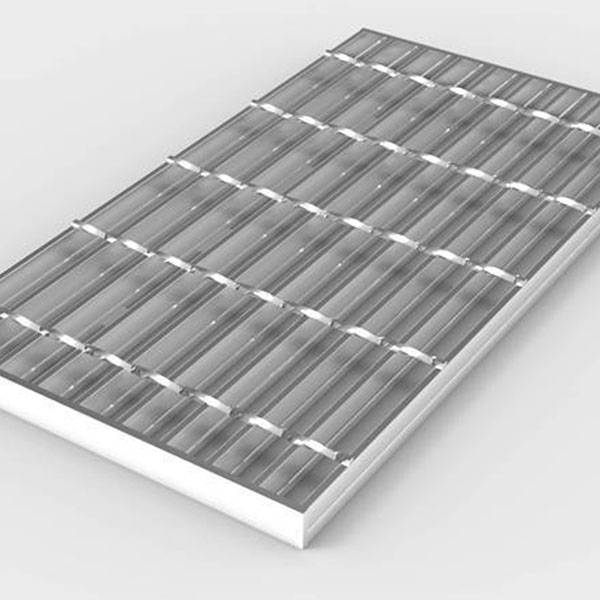

✔️ Construction

-

Gratings

-

Pultruded profiles

-

plaques d'égout

-

Rebar and wall panels

✔️ Transport

-

Automotive body parts

-

Truck panels

-

RV exteriors

✔️ Consumer and Utility Products

-

Bathtubs and sinks

-

Shower trays

-

Chemical-resistant countertops

5. Processing Methods

Isophthalic resins are suitable for a wide range of processing techniques:

| Method | Suitability |

|---|---|

| Hand lay-up | Excellent |

| Spray-up | Excellent |

| Filament winding | Excellent |

| Pultrusion | Very good |

| Compression molding | Bien |

| Resin transfer molding | Acceptable with modified resin |

Curing Agents:

Typically cured with MEKP ou BPO (benzoyl peroxide) in combination with cobalt accelerators et promoters.

Temps de gel:

Adjustable depending on formulation and catalyst system, typically 8–30 minutes at ambient temperature.

6. Fiche technique (FT)

Below is a sample TDS for Résine de polyester insaturée isophtalique. Actual values may vary slightly depending on formulation and manufacturer.

📌 General Properties

| Propriété | Valeur typique | Méthode d'essai |

|---|---|---|

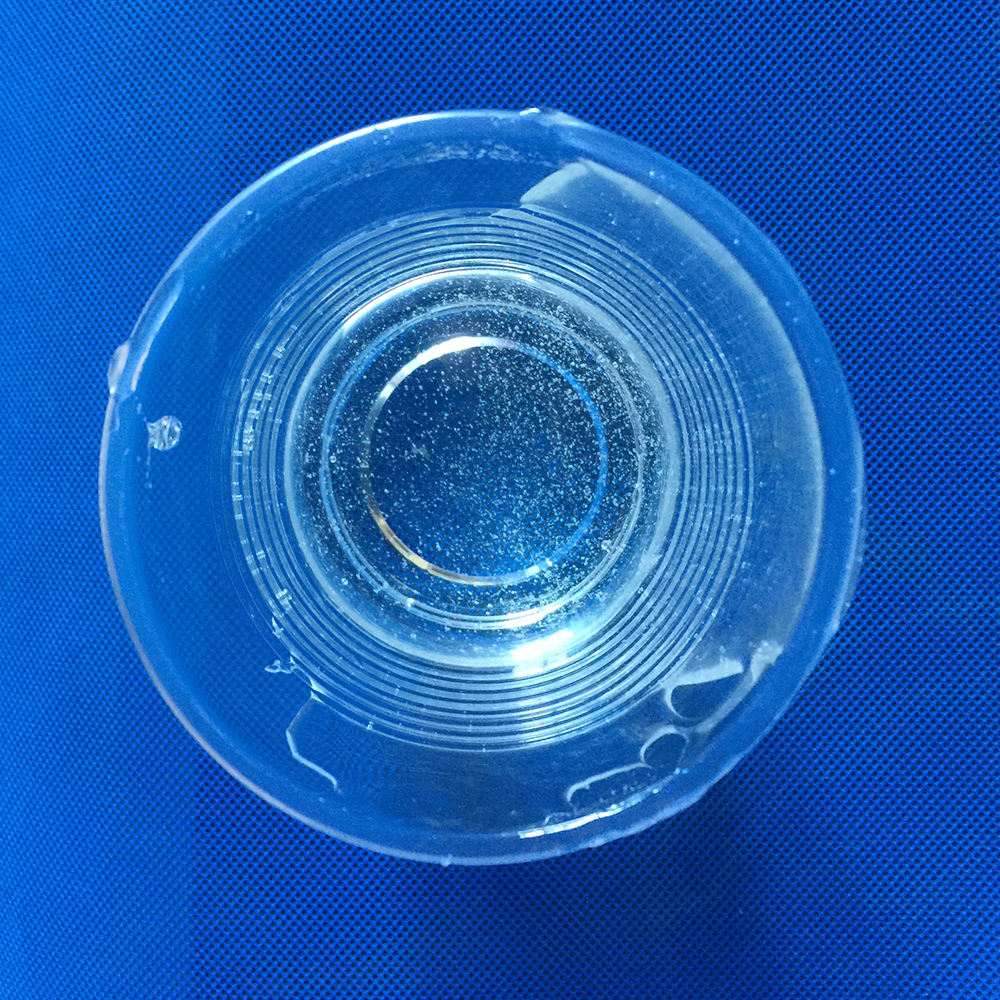

| Apparence | Clear to pale yellow liquid | Visuel |

| Viscosity @ 25°C (mPa·s) | 400 – 650 | Brookfield LV, #3/60rpm |

| Acid Number (mg KOH/g) | 15 – 25 | ISO 2114 |

| Solid Content (%) | 60 – 70 | ISO 3251 |

| Monomer Content (Styrene %) | 30 – 40 | GC Method |

| Gel Time @ 25°C (3 phr MEKP) | 12 – 18 minutes | ISO 2535 |

| durée de conservation | 6 months @ ≤ 25°C | — |

🔧 Mechanical Properties (Cured Resin)

| Propriété | Valeur typique | Méthode d'essai |

|---|---|---|

| Tensile Strength (MPa) | 60 – 80 | ISO 527 |

| Tensile Modulus (GPa) | 3.0 – 3.5 | ISO 527 |

| Elongation at Break (%) | 2.0 – 3.5 | ISO 527 |

| Flexural Strength (MPa) | 100 – 120 | ISO 178 |

| Flexural Modulus (GPa) | 3.5 – 4.2 | ISO 178 |

| Izod Impact Strength (kJ/m²) | 6 – 10 | ISO 180 |

| Dureté Barcol | 35 – 45 | ASTM D2583 |

🌡️ Thermal and Chemical Resistance

| Propriété | Valeur typique | Méthode d'essai |

|---|---|---|

| Heat Deflection Temp (HDT °C) | 80 – 120 | ISO 75 |

| Water Absorption (%) | < 0.3 | ISO 62 |

| Thermal Conductivity (W/m·K) | ~0.2 | ISO 22007 |

| Flammability | Self-extinguishing (with filler) | UL94 |

| Résistance chimique | Excellent to acids & saltwater | In-house test |

7. Storage and Handling

-

Store in original, sealed containers in a cool, dry, and shaded area.

-

Avoid direct sunlight and keep away from open flames or ignition sources.

-

Use proper PPE including gloves, goggles, and a respirator if necessary.

-

Ensure good ventilation during use.

-

Observe standard fire safety procedures—unsaturated polyester resins are flammable.

8. Safety Information

-

Se référer à Fiche de données de sécurité (FDS) before handling.

-

Vapors may cause respiratory irritation—use in well-ventilated areas.

-

Avoid contact with skin and eyes.

-

Utiliser explosion-proof equipment in storage and mixing areas.

9. Packaging Options

Isophthalic UPR is commonly available in the following packaging formats:

| Packaging Type | Lester |

|---|---|

| Metal Drums | 220–240 kg |

| IBC Totes | 1000 kg |

| Bulk ISO Tank | ≥ 20,000 kg |

10. Conclusion

Isophthalic Unsaturated Polyester Resin offers a perfect balance between performance and cost for a wide range of composite applications. Its enhanced strength, chemical durability, et resistance to weathering and thermal degradation make it the ideal choice for customers seeking more than just a general-purpose resin.

Whether you’re building chemical tanks, marine decks, corrosion-resistant ductwork, or high-strength FRP panels, isophthalic UPR delivers long-term performance, reliability, and value.

Résine de polyester insaturée isophtalique

Série :

Produits mandataires >application

revêtements, adhésifs et composites

Nom du produit :

o-phthalic resin

FAQ

Q :

What are the main applications of o-Phthalic Unsaturated Polyester Resin?

UN :

o-Phthalic UPR is widely used in general-purpose fiberglass-reinforced plastic (FRP) applications such as gratings, tanks, bathtubs, pipes, panels, and decorative components. It is especially suited for environments requiring moderate mechanical strength and cost-efficiency, but not intended for aggressive chemical or high-temperature conditions.

Q :

How does it compare to isophthalic and vinyl ester resins?

UN :

Cost: o-Phthalic is more economical. Performance: It has lower chemical and thermal resistance compared to isophthalic or vinyl ester resins. Usage: Choose o-Phthalic for general use, isophthalic for stronger corrosion/thermal needs, and vinyl ester for high-performance or corrosive environments.

Q :

How do I store and handle o-Phthalic resin safely?

UN :

Store in cool (5–25°C), dry, well-ventilated areas. Keep away from heat, ignition sources, and sunlight. Use sealed containers, ideally nitrogen-blanketed. Always wear protective gloves, goggles, and use fume extraction when handling. Follow your supplier's MSDS for detailed safety procedures.

Q :

Can o-Phthalic resin be pigmented or filled?

UN :

Yes. o-Phthalic resin is compatible with polyester-compatible pigments and fillers (e.g., calcium carbonate, ATH). Add pigments and fillers before mixing in the curing agents. Keep the viscosity in check if adding fillers to avoid poor wet-out of reinforcements.

Q :

How long is the shelf life of o-Phthalic resin, and how can it be extended?

UN :

Typical shelf life is 3 to 6 months when stored in ideal conditions (below 25°C in a sealed container). To extend shelf life: Ensure resin is stabilized with hydroquinone or MEHQ inhibitors. Store in dark, cool environments. Avoid frequent opening of containers to limit oxygen and moisture exposure.

Autres produits connexes