Pengenalan kinerja produk

Fiberglass grating with a solid top and diamond surface is a premium structural panel designed for environments requiring both strength and safety. Unlike traditional open-mesh fiberglass reinforced plastic (FRP) grating, the solid top configuration provides a completely sealed surface, making it ideal for areas where containment of debris, liquids, or chemicals is necessary. The solid surface also eliminates trip hazards caused by small objects falling through grating gaps, contributing to a cleaner, safer workspace.

One of the standout features of this grating type is the diamond-pattern anti-slip surface, which enhances foot traction significantly. The raised diamond texture offers superior slip resistance—even when the panel is wet, oily, or contaminated—making it suitable for industrial facilities, chemical plants, food processing areas, or marine environments. It complies with OSHA safety standards and helps reduce workplace accidents caused by slips and falls.

Constructed from high-strength fiberglass reinforced resin, the solid top grating offers excellent corrosion resistance, making it ideal for harsh and corrosive environments where steel or aluminum would quickly degrade. It is non-conductive, lightweight, and easy to fabricate, often eliminating the need for heavy lifting equipment during installation. Moreover, the product can be supplied in fire-retardant formulations or customized with UV inhibitors, depending on application needs.

Additionally, fiberglass solid top grating offers sound-dampening properties, helping reduce noise in high-traffic areas. It also protects underlying structures and systems from exposure to chemicals or mechanical wear. Available in various resin systems—such as isophthalic, vinyl ester, and phenolic—it can be tailored to specific chemical resistance requirements.

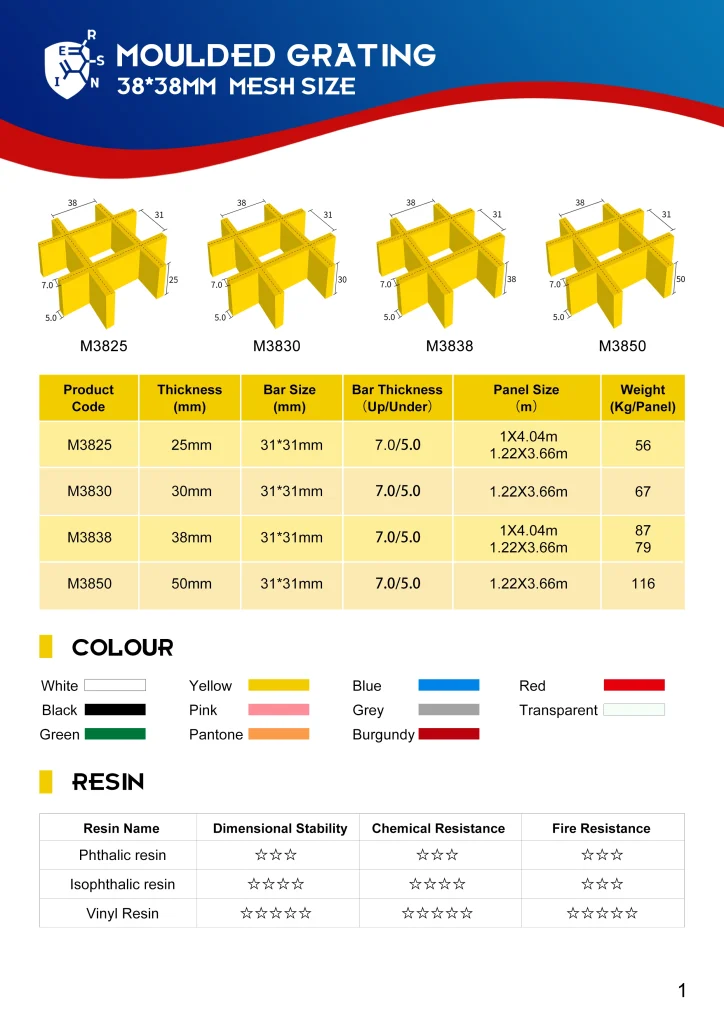

FRP Grating Specifications & Technical Parameters

1.General Specifications

| Barang | Keterangan |

|---|---|

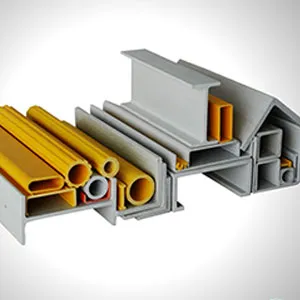

| Product Type | Molded FRP Grating / Pultruded FRP Grating |

| Mesh Size | 38×38 mm (1.5″x1.5″) / 40×40 mm / Custom |

| Thickness (Height) | 25 mm / 30 mm / 38 mm / 50 mm |

| Ukuran Panel | 1220×3660 mm / 1000×4000 mm / Custom |

| Open Area | 60% – 70% (depending on mesh size) |

| Opsi Permukaan | Gritted / Concave / Smooth / Covered Top |

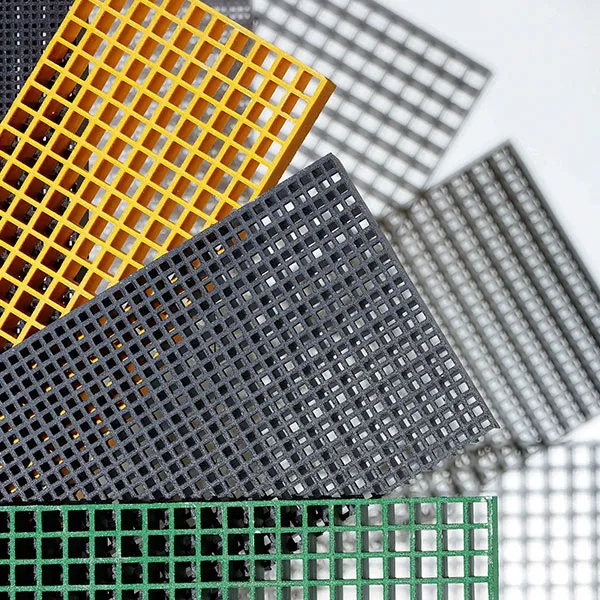

| Warna | Gray, Yellow, Green, Red, Custom |

2. Mechanical Properties (Typical Values)

| Properti | Nilai | Test Standard |

|---|---|---|

| Daya tarik | ≥ 120 MPa (17,400 psi) | ASTM D638 |

| Kekuatan Lentur | ≥ 200 MPa (29,000 psi) | ASTM D790 |

| Modulus Lentur | ≥ 7,800 MPa (1.13×10⁶ psi) | ASTM D790 |

| Kekuatan Kompresi | ≥ 200 MPa (29,000 psi) | ASTM D695 |

| Impact Strength (Izod) | ≥ 85 J/m | ASTM D256 |

| Kekerasan Barcol | ≥ 40 | ASTM D2583 |

3. Physical & Chemical Properties

| Properti | Nilai | Test Standard |

|---|---|---|

| Kepadatan | ~1.8–2.0 g/cm³ | ASTM D792 |

| Water Absorption | < 0.5% | ASTM D570 |

| Flame Retardancy | ≤ 25 (Class 1) | ASTM E84 |

| Resistensi UV | Available with UV inhibitor | – |

| Konduktivitas Listrik | Tidak konduktif | – |

| Thermal Conductivity | ~0.25 W/m·K | ASTM C177 |

| Operating Temperature Range | -50°C to +120°C (varies by resin) | – |

4. Resin Systems Available

| Resin Type | Fitur | Application Areas |

|---|---|---|

| Orthophthalic | General purpose, cost-effective | General industry, flooring |

| Isophthalic | Improved chemical resistance | Wastewater, food processing |

| Vinil Ester | Excellent chemical and corrosion resistance | Chemical plants, offshore, mining |

| Fenolik | Fire and smoke resistance | Oil & gas, transport, marine |

5. Load Table (Example for 38mm Thick Grating)

| Rentang (mm) | Load (kN/m²) | Lendutan (mm) |

|---|---|---|

| 600 | 5.0 | 4.5 |

| 800 | 3.5 | 5.9 |

| 1000 | 2.0 | 7.6 |

Why Choose Us

Expertise in FRP Grating Manufacturing

With over 20 years of experience, our factory specializes exclusively in the design, development, and production of high-performance FRP (Fiberglass Reinforced Plastic) gratings. Our deep industry knowledge ensures that every product meets the most demanding industrial standards.

Advanced Technology and Equipment

We utilize state-of-the-art manufacturing equipment and precision molding technology to produce gratings with superior strength, corrosion resistance, and dimensional accuracy. Our commitment to innovation means your project benefits from the latest advancements in FRP technology.

Customized Solutions

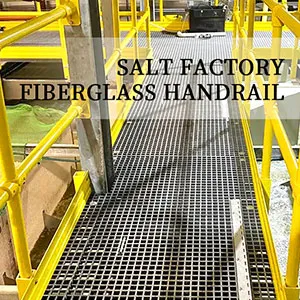

From panel sizes and resin types to surface finishes and colors, we offer complete customization to meet your unique application needs—be it industrial flooring, stair treads, trench covers, or marine platforms.

Stringent Quality Control

Every product undergoes a rigorous quality inspection process, including load testing, flame retardance checks, and corrosion resistance analysis. Our ISO-certified quality management system ensures consistent excellence in every batch.

Competitive Pricing

We offer factory-direct pricing without compromising on quality. With optimized production processes and bulk manufacturing capabilities, we help our customers achieve cost savings at scale.

Reliable Delivery and Global Reach

We maintain a large stock of standard products and operate a streamlined logistics system, ensuring fast delivery times locally and internationally. We’ve successfully served clients in over 15 countries.

Hot-Selling Products

| Standard Panel Sizes | 1220 mm × 3660 mm (4 ft × 12 ft) 1220 mm × 4000 mm (4 ft × 13.1 ft) 915 mm × 3050 mm (3 ft × 10 ft) 1000 mm × 3000 mm (customizable) (Other sizes can be customized according to project needs) |

| Thickness Options | 25 mm (1 inci) 30 mm (1.2 inch) 38 mm (1.5 inch) — most common 50 mm (2 inch) |

| Mesh Size (Opening Size) | 38 mm × 38 mm (1.5 inch × 1.5 inch) — Standard 40 mm × 40 mm 19 mm × 19 mm (mini-mesh for small object passage prevention) |

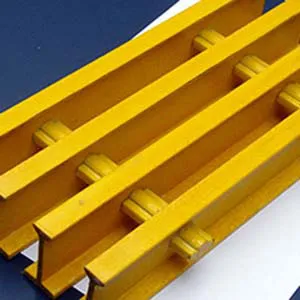

| Load Bar Width and Spacing (for Pultruded Grating) | Load bar width: typically 25 mm, 38 mm, 50 mm Load bar spacing: 25 mm, 40 mm, 50 mm center-to-center |

| Opsi Permukaan | Gritted surface (anti-slip) Permukaan halus Covered surface (solid top) |

| Colors Available | Yellow (most common) Hijau Grey Red Customized colors upon request |

| Common Resin Types | Isophthalic Polyester (standard corrosion resistance) Vinyl Ester (high chemical resistance) Phenolic (fire-resistant applications) |

About the Factory

Anhui Tianfu New Material Co., Ltd is a leading professional manufacturer specializing in FRP moulded grating production. With over 20 years of experience in the composite materials industry, we are dedicated to delivering high-quality fiberglass reinforced plastic (FRP) solutions for a wide range of industrial and commercial applications. Our modern factory is equipped with advanced production lines, covering an area of more than 26,000 square meters. We offer a complete range of molded FRP gratings featuring superior strength, chemical resistance, fire retardancy, and anti-slip performance. At Tianfu New Material, we prioritize innovation, strict quality control, and customer satisfaction. Our products are certified to international standards and exported to over 30 countries worldwide, serving industries such as chemical plants, sewage treatment facilities, offshore platforms, and walkways. Whether you need standard sizes or customized solutions, Tianfu is your reliable partner for FRP moulded grating.

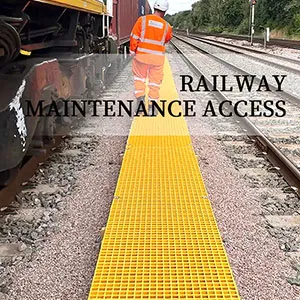

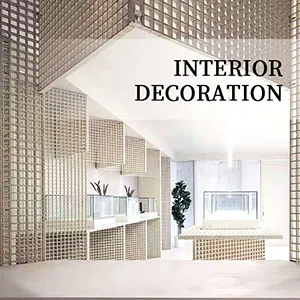

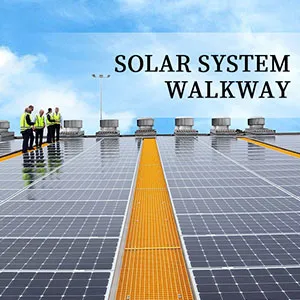

Application Scenarios

About the Factory

We are a professional FRP Grating manufacturer with 20+ years of experience. Our 26,000㎡ factory is ISO9001 certified, serving clients across 30+ countries with OEM/ODM capability. We provide customized solutions and fast delivery worldwide.

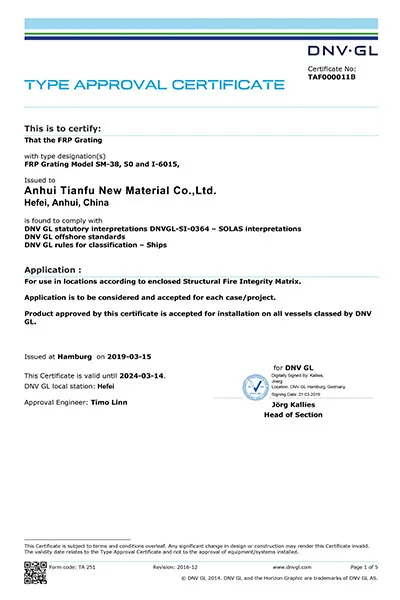

Our FRP gratings are manufactured in accordance with ISO 9001 standards and tested per ASTM E84 (Class 1 fire rating), ASTM D638/D790 for mechanical performance, and comply with BS 476 and EN 13706 standards. Third-party testing available through SGS and TUV upon request.

Pameran

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

Certificate

FRP Moulded Grating TDS

Other Products

VR Factory Tour

Fiberglass Grating Solid Top-diamond Surface

aplikasi

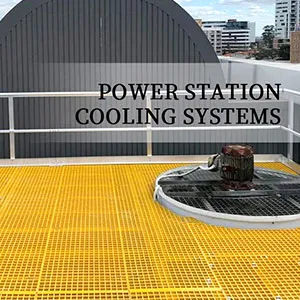

Industrial Flooring,Marine and Offshore Platforms,Wastewater Treatment Plants,Food and Beverage Industry,Transportation Infrastructure,Construction Sites,Battery Rooms and Electrical Substations,Public and Commercial Spaces,Water Parks and Swimming Pools,Rooftop and HVAC Systems

Mesh Size :

38x38 mm (1.5

Thickness (Height) :

25 mm / 30 mm / 38 mm / 50 mm

Panel Size :

1220x3660 mm / 1000x4000 mm / Custom

Open Area :

60% – 70% (depending on mesh size)

Surface Options :

Gritted / Concave / Smooth / Covered Top

Warna :

Gray, Yellow, Green, Red, Custom

Pertanyaan Umum

Q :

Where is diamond-surface solid top grating typically used?

A :

It’s commonly used in environments that require spill containment, cleanliness, or enhanced safety, such as: Chemical plants Food and beverage facilities Water treatment plants Offshore platforms Walkways and platforms in manufacturing zones

Q :

Is the diamond-pattern surface slip-resistant?

A :

Yes. The raised diamond pattern offers excellent slip resistance, even in wet, oily, or chemically exposed environments. It helps prevent accidents and meets many industrial safety standards.

Q :

Can it handle heavy loads?

A :

Yes, depending on the thickness and support span. Solid top fiberglass grating is engineered for strength and can support pedestrian traffic and moderate equipment loads, but it’s essential to choose the correct specifications for your application.

Q :

Is solid top grating resistant to chemicals and corrosion?

A :

Absolutely. It is highly resistant to a wide range of chemicals and does not corrode like steel or aluminum, making it ideal for harsh or corrosive environments.

Q :

Is it fire retardant?

A :

Many solid top grating panels are available in fire-retardant formulations that meet ASTM E84 standards for flame spread and smoke development.

Q :

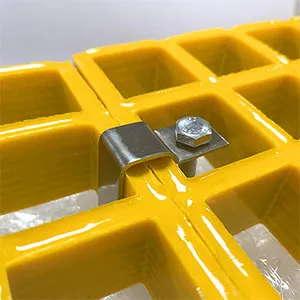

How is it installed?

A :

It can be installed with stainless steel clips or fasteners, and it’s easily cut to fit with standard hand tools—no hot work needed.

Produk terkait lainnya