Pengenalan kinerja produk

Plastic grating, also known as FRP (Fiberglass Reinforced Plastic) grating, is a modern alternative to traditional metal grating. Made from fiberglass strands embedded in a thermosetting resin matrix, plastic grating offers a strong, lightweight, and corrosion-resistant solution for a wide range of applications. It is especially popular in environments where metal would corrode quickly or require frequent maintenance, such as chemical plants, wastewater facilities, marine docks, and food processing areas.

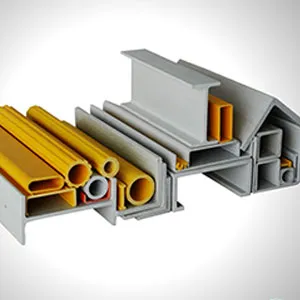

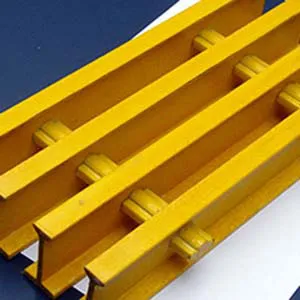

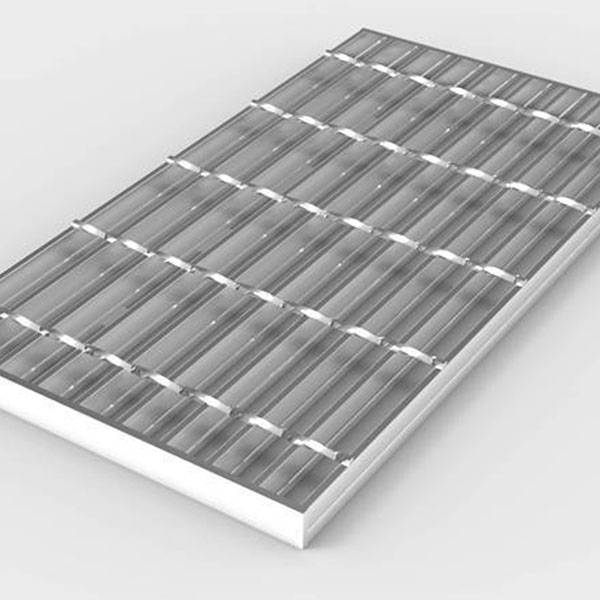

Available in both molded Dan pultruded types, plastic grating provides excellent strength-to-weight ratios and can withstand harsh chemicals, UV exposure, moisture, and impact. Molded grating is formed in one piece for multidirectional strength and is ideal for areas with pedestrian traffic or where drainage and slip resistance are priorities. Pultruded grating, made by pulling continuous fiberglass strands through resin and shaping them into bars, is stronger in the load-bearing direction and suitable for heavy-duty applications.

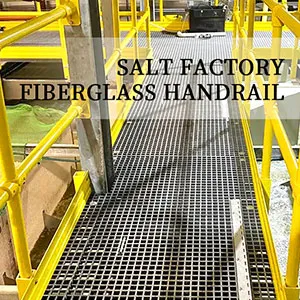

One of the key benefits of plastic grating is its non-conductive, non-magnetic, Dan fire-retardant properties, making it ideal for electrical safety and high-risk industrial zones. It also offers a slip-resistant surface—especially when molded with grit or serrated top layers—enhancing workplace safety.

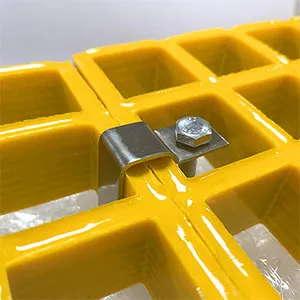

Plastic grating is easy to cut, install, and maintain, and its low weight reduces transportation and handling costs. Its longer lifespan and minimal maintenance requirements make it a cost-effective choice over time.

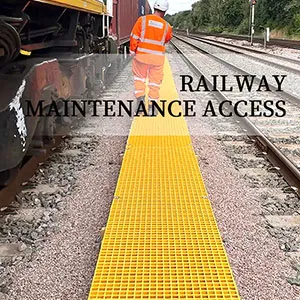

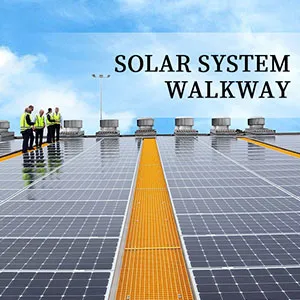

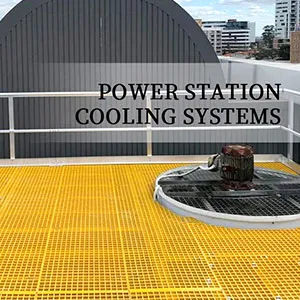

Whether used for trench covers, catwalks, mezzanine floors, stairs, or rooftop walkways, plastic grating delivers both performance and value in environments that challenge conventional materials.

Plastic Grating Specifications & Technical Parameters

| Parameter | Specification Options |

|---|---|

| Komposisi Bahan | Fiberglass Reinforced Plastic (FRP) with Polyester, Vinyl Ester, or Phenolic Resin |

| Jenis | Molded FRP Grating, Pultruded FRP Grating |

| Opsi Permukaan | Concave (standard), Grit-top (anti-slip), Covered (solid surface) |

| Ukuran Jala | 38×38 mm (1.5″x1.5″), 50×50 mm (2″x2″), Mini Mesh: 19×19 mm (¾”x¾”) |

| Grating Height (Thickness) | 25 mm, 30 mm, 38 mm, 50 mm, 60 mm |

| Ukuran Panel | Standard: 1220×3660 mm (4’x12′), 1000×3000 mm; Custom sizes available |

| Kapasitas beban | Varies by thickness and span; typically 500–2000 kg/m² (light to heavy-duty use) |

| Area Terbuka | 60% – 70% for standard mesh; lower for covered or mini mesh types |

| Operating Temperature | -40°C to +120°C continuous; up to 180°C for phenolic-based FRP |

| Ketahanan Api | Available (meets ASTM E84 Class 1, UL94 V-0 for select resins) |

| Resistensi UV | UV inhibitors added; suitable for outdoor use |

| Tahan korosi | Excellent against acids, alkalis, salts, solvents |

| Konduktivitas Listrik | Non-conductive, ideal for electrical or high-voltage environments |

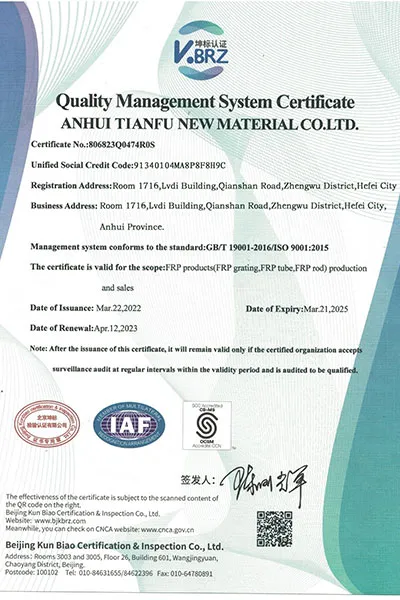

| Sertifikasi | ISO 9001, ASTM E84, OSHA, ANSI, BS 4592 (varies by manufacturer and application) |

Mengapa Memilih Kami

Keahlian dalam Pembuatan Kisi-kisi FRP

Dengan pengalaman lebih dari 20 tahun, pabrik kami khusus bergerak di bidang desain, pengembangan, dan produksi kisi-kisi FRP (Fiberglass Reinforced Plastic) berkinerja tinggi. Pengetahuan industri kami yang mendalam memastikan bahwa setiap produk memenuhi standar industri yang paling ketat.

Teknologi dan Peralatan Canggih

Kami menggunakan peralatan manufaktur canggih dan teknologi pencetakan presisi untuk menghasilkan kisi-kisi dengan kekuatan, ketahanan korosi, dan akurasi dimensi yang unggul. Komitmen kami terhadap inovasi berarti proyek Anda akan mendapatkan manfaat dari kemajuan terbaru dalam teknologi FRP.

Solusi yang Disesuaikan

Mulai dari ukuran panel dan jenis resin hingga lapisan permukaan dan warna, kami menawarkan kustomisasi lengkap untuk memenuhi kebutuhan aplikasi unik Anda—baik itu lantai industri, anak tangga, penutup parit, atau platform kelautan.

Kontrol Kualitas yang Ketat

Setiap produk menjalani proses inspeksi kualitas yang ketat, termasuk pengujian beban, pemeriksaan ketahanan api, dan analisis ketahanan korosi. Sistem manajemen kualitas bersertifikasi ISO kami memastikan keunggulan yang konsisten di setiap batch.

Harga Kompetitif

Kami menawarkan harga langsung dari pabrik tanpa mengorbankan kualitas. Dengan proses produksi yang dioptimalkan dan kemampuan manufaktur massal, kami membantu pelanggan kami mencapai penghematan biaya dalam skala besar.

Pengiriman Andal dan Jangkauan Global

Kami memiliki stok produk standar yang besar dan mengoperasikan sistem logistik yang efisien, memastikan waktu pengiriman yang cepat baik di dalam maupun luar negeri. Kami telah berhasil melayani klien di lebih dari 15 negara.

Produk Terlaris

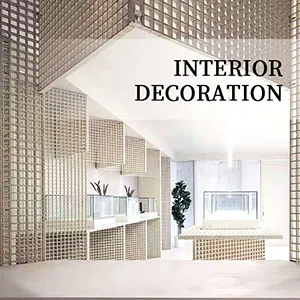

Skenario Aplikasi

Tentang Pabrik

Kami adalah produsen kisi-kisi FRP profesional dengan pengalaman lebih dari 20 tahun. Pabrik kami seluas 26.000㎡ bersertifikasi ISO9001, melayani klien di lebih dari 30 negara dengan kemampuan OEM/ODM. Kami menyediakan solusi yang disesuaikan dan pengiriman cepat ke seluruh dunia.

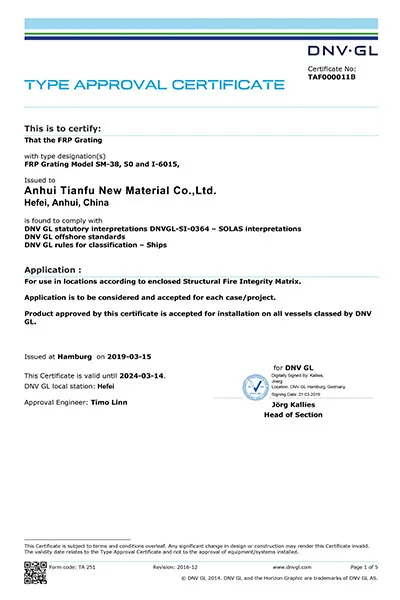

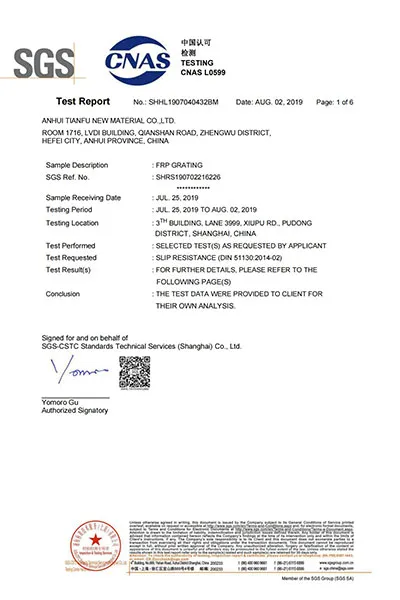

Kisi-kisi FRP kami diproduksi sesuai dengan standar ISO 9001 dan diuji sesuai dengan ASTM E84 (peringkat tahan api Kelas 1), ASTM D638/D790 untuk kinerja mekanis, serta memenuhi standar BS 476 dan EN 13706. Pengujian pihak ketiga tersedia melalui SGS dan TUV berdasarkan permintaan.

Pameran

JEC WORLD 2023

JEC WORLD 2024

CAMX 2025

SHANGHAI 2025

Sertifikat

Produk Lainnya

Tur Pabrik VR

Kisi Plastik

aplikasi

Industrial Facilities,Wastewater Treatment Plants,Marine & Offshore Platforms,Food & Beverage Processing,Electrical & Utility Areas,Mining & Metal Processing,Architectural & Public Infrastructure

Jenis :

Molded FRP Grating, Pultruded FRP Grating

Opsi Permukaan:

Concave (standard), Grit-top (anti-slip), Covered (solid surface)

Ukuran Jala:

38×38 mm (1.5"x1.5"), 50×50 mm (2"x2"), Mini Mesh: 19×19 mm (¾"x¾")

Grating Height (Thickness) :

25 mm, 30 mm, 38 mm, 50 mm, 60 mm

Ukuran Panel:

Standard: 1220×3660 mm (4'x12'), 1000×3000 mm; Custom sizes available

Pertanyaan Umum

Q :

What is plastic grating made of?

A :

Plastic grating is typically made from Fiberglass Reinforced Plastic (FRP), combining fiberglass strands with a thermosetting resin such as polyester, vinyl ester, or phenolic for strength and chemical resistance.

Q :

What is the difference between molded and pultruded plastic grating?

A :

Molded grating offers bi-directional strength and is ideal for general-purpose use with moderate loads. Pultruded grating is stronger in one direction and better suited for heavy loads or long spans.

Q :

Where is plastic grating commonly used?

A :

Plastic grating is used in chemical plants, wastewater facilities, marine environments, food processing areas, oil platforms, and walkways or platforms where corrosion resistance and safety are crucial.

Q :

Is plastic grating slip-resistant?

A :

Yes, most plastic gratings come with a concave or grit-top surface to enhance slip resistance, especially in wet, oily, or high-traffic environments.

Q :

Can plastic grating withstand harsh chemicals?

A :

Absolutely. Plastic grating has excellent chemical resistance, especially when made with vinyl ester or phenolic resins, making it suitable for corrosive environments.

Q :

Is plastic grating fire-retardant?

A :

Yes. Fire-retardant formulations are available that meet standards like ASTM E84 Class 1 and UL94 V-0, depending on the resin type used.

Q :

Can plastic grating be cut or customized on-site?

A :

Yes. Plastic grating can be easily cut using standard tools, and customized shapes, holes, or notches can be made on-site without compromising structural integrity.

Produk terkait lainnya