Introdução ao desempenho do produto

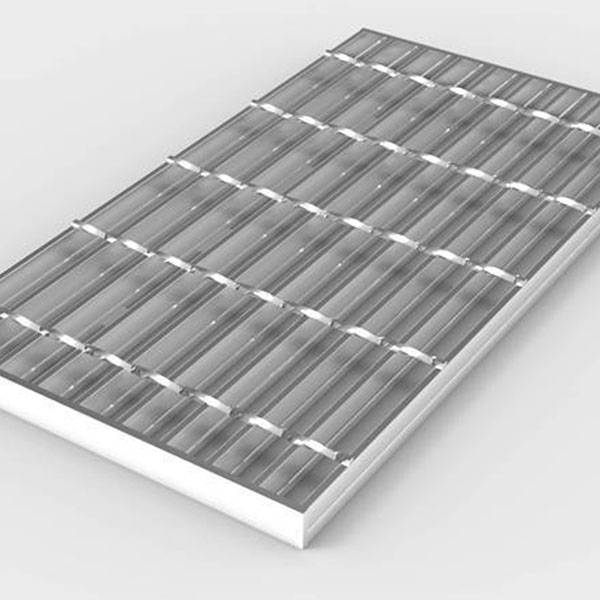

1. Visão geral das grelhas de aço inoxidável

As grades de aço inoxidável são componentes estruturais altamente duráveis e resistentes à corrosão, amplamente utilizados nos setores industrial, comercial e arquitetônico. Conhecidas por sua resistência, durabilidade e apelo estético, as grades de aço inoxidável são comumente encontradas em fábricas químicas, instalações de processamento de alimentos, ambientes marítimos e projetos arquitetônicos modernos.

2. Especificações Técnicas

2.1 Tipos de Grelhas de Aço Inoxidável

As grades de aço inoxidável podem ser categorizadas com base em seu processo de fabricação e capacidade de carga pretendida:

1. Grelha de aço inoxidável soldada

Este tipo de grelha é formado pela soldagem das barras de suporte e das barras transversais em altas temperaturas, criando uma grelha durável e de alta resistência. É amplamente utilizada em pisos industriais, tampas de drenagem e plataformas para cargas pesadas.

2. Grelha de aço inoxidável com sistema de encaixe por pressão

Neste modelo, as barras transversais são prensadas nas barras de suporte sob alta pressão, garantindo um acabamento liso e uniforme. Este tipo de grelha é frequentemente escolhido para aplicações arquitetônicas onde a estética é importante.

3. Grelha de aço inoxidável com encaixe por compressão

Fabricadas por meio de um processo de estampagem que fixa as barras transversais às barras de suporte, as grades estampadas oferecem rigidez e resistência excepcionais. São ideais para passarelas, passarelas elevadas e ambientes industriais.

4. Grelha rebitada de aço inoxidável

A grade rebitada incorpora conexões rebitadas entre os suportes e as barras transversais, oferecendo excelente desempenho de suporte de carga. Este tipo é ideal para áreas que exigem grande circulação de veículos.

2.2 Composição do Material

-

Tipos comuns de aço inoxidável304, 316, 316L (alta resistência à corrosão para ambientes agressivos)

-

Barras de apoioA espessura varia entre 2 mm e 10 mm, sendo fabricada em aço inoxidável de alta resistência.

-

Barras transversaisDisponível em hastes quadradas torcidas ou barras redondas para maior integridade estrutural.

-

Acabamentos de superfícieAcabamento bruto, eletropolido ou passivado para maior durabilidade.

2.3 Opções de Tratamento de Superfície

-

EletropolimentoAumenta a resistência à corrosão e melhora o apelo visual.

-

PassivaçãoRemove impurezas e prolonga a vida útil.

-

Jateamento com microesferasCria um acabamento fosco, comumente usado em projetos arquitetônicos.

3. Tamanhos e configurações padrão

3.1 Dimensões do painel

-

Larguras comuns: 600 mm, 800 mm, 1000 mm ou especificações personalizadas.

-

Opções de comprimento: 1000 mm, 1200 mm, 1500 mm, 2000 mm, até 3000 mm.

-

Dimensões personalizadasDisponível conforme as necessidades do projeto.

3.2 Espaçamento da barra de apoio

-

Espaçamentos padrão: 19mm, 30mm, 40mm.

-

Configurações de carga pesadaEspaçamento de 50 mm ou mais para tráfego de veículos.

3.3 Espaçamento da barra transversal

-

Distâncias típicas38 mm, 50 mm ou sob medida, de acordo com as necessidades do cliente.

3.4 Capacidade de Carga

-

Varia de 500 kg/m² a 5000 kg/m², dependendo da espessura e do espaçamento das barras.

4. Principais características de desempenho

4.1 Resistência à corrosão

As grelhas de aço inoxidável são altamente resistentes à oxidação, ferrugem e exposição a produtos químicos agressivos, tornando-as a escolha preferida para ambientes marítimos, alimentícios e de processamento químico.

4.2 Resistência e Durabilidade Estrutural

-

A grade soldada proporciona uma estabilidade mecânica excepcional.

-

Os modelos robustos são adequados para veículos como empilhadeiras e transportadores industriais.

4.3 Propriedades Antiderrapantes

-

A grade serrilhada de aço inoxidável melhora a tração, reduzindo o risco de escorregamento em condições de piso molhado.

4.4 Resistência ao fogo

-

Material não combustível, garantindo um alto nível de segurança contra incêndio em ambientes industriais.

5. Aplicações comuns de grelhas de aço inoxidável

-

Fábricas de Processamento de AlimentosRevestimentos de piso higiênicos em ambientes estéreis.

-

Plataformas marítimas e offshorePassarelas e decks resistentes à corrosão.

-

Instalações de Processamento QuímicoTolera a exposição a substâncias agressivas.

-

Passarelas e caminhos industriaisSoluções de piso seguras para áreas de alto tráfego.

-

Degraus de escadaOferece características antiderrapantes para segurança no local de trabalho.

-

Recintos de segurançaUtilizado em soluções de barreiras e cercas.

Grelha de aço inoxidável

Series :

Produtos proxy >aplicativo

Indústrias de Processamento de Alimentos: Pisos higiênicos em ambientes estéreis. Plataformas Marítimas e Offshore: Passarelas e decks resistentes à corrosão. Instalações de Processamento Químico: Tolerância à exposição a substâncias agressivas. Passarelas e Passarelas Industriais: Soluções de piso seguras para áreas de alto tráfego. Degraus de Escada: Oferecem características antiderrapantes para segurança no local de trabalho. Cercas de Segurança: Utilizadas em soluções de barreiras e cercas.

Perguntas frequentes

Outros produtos relacionados