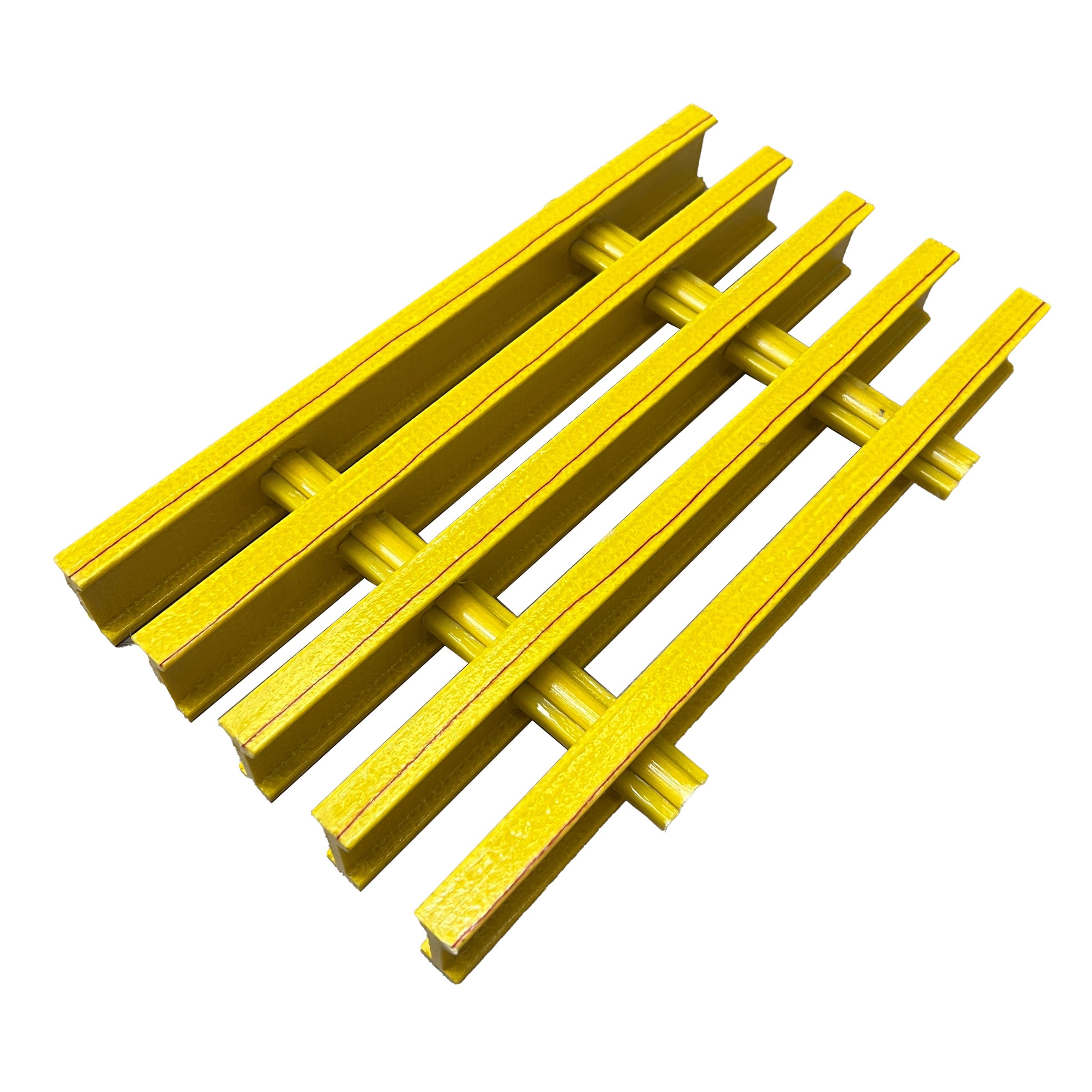

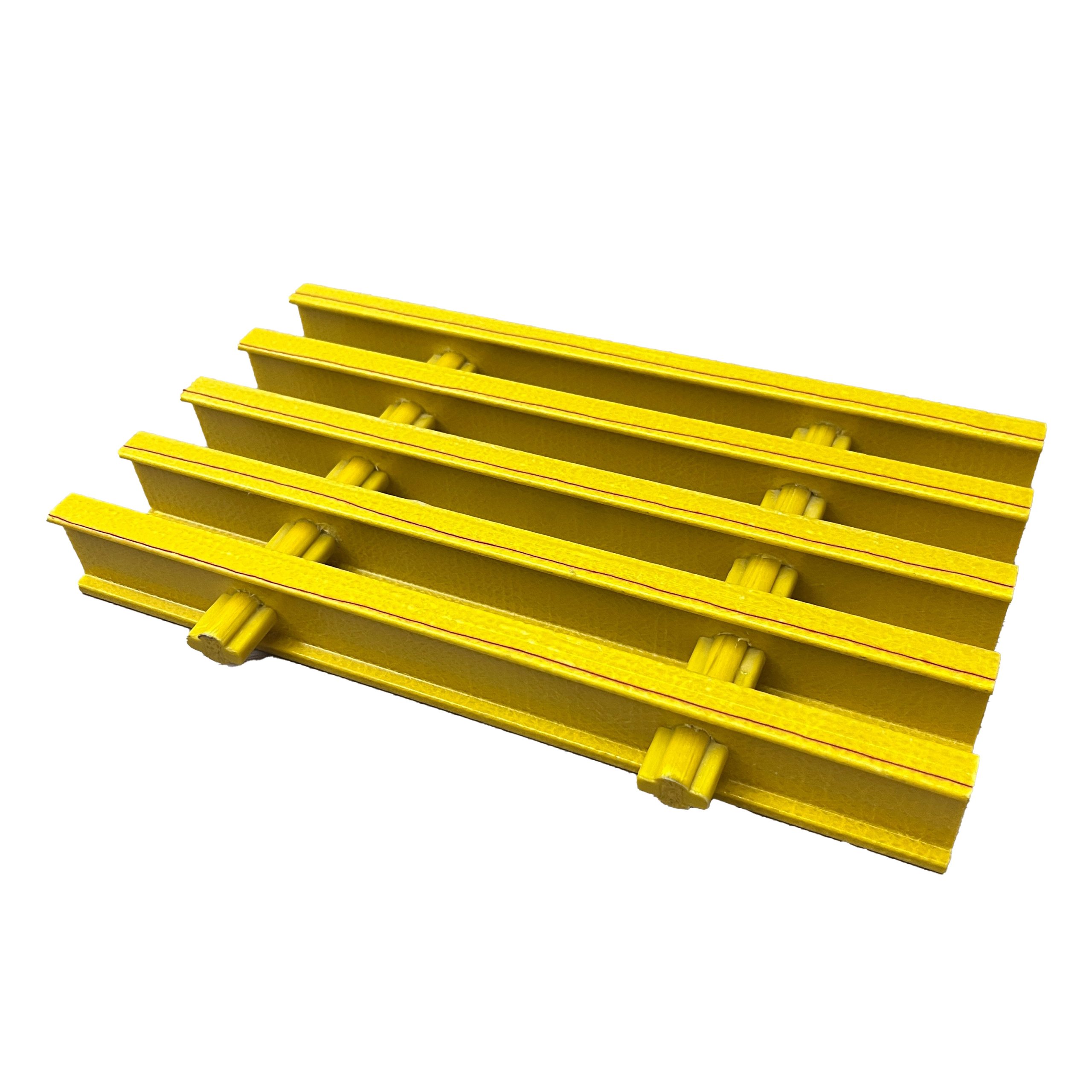

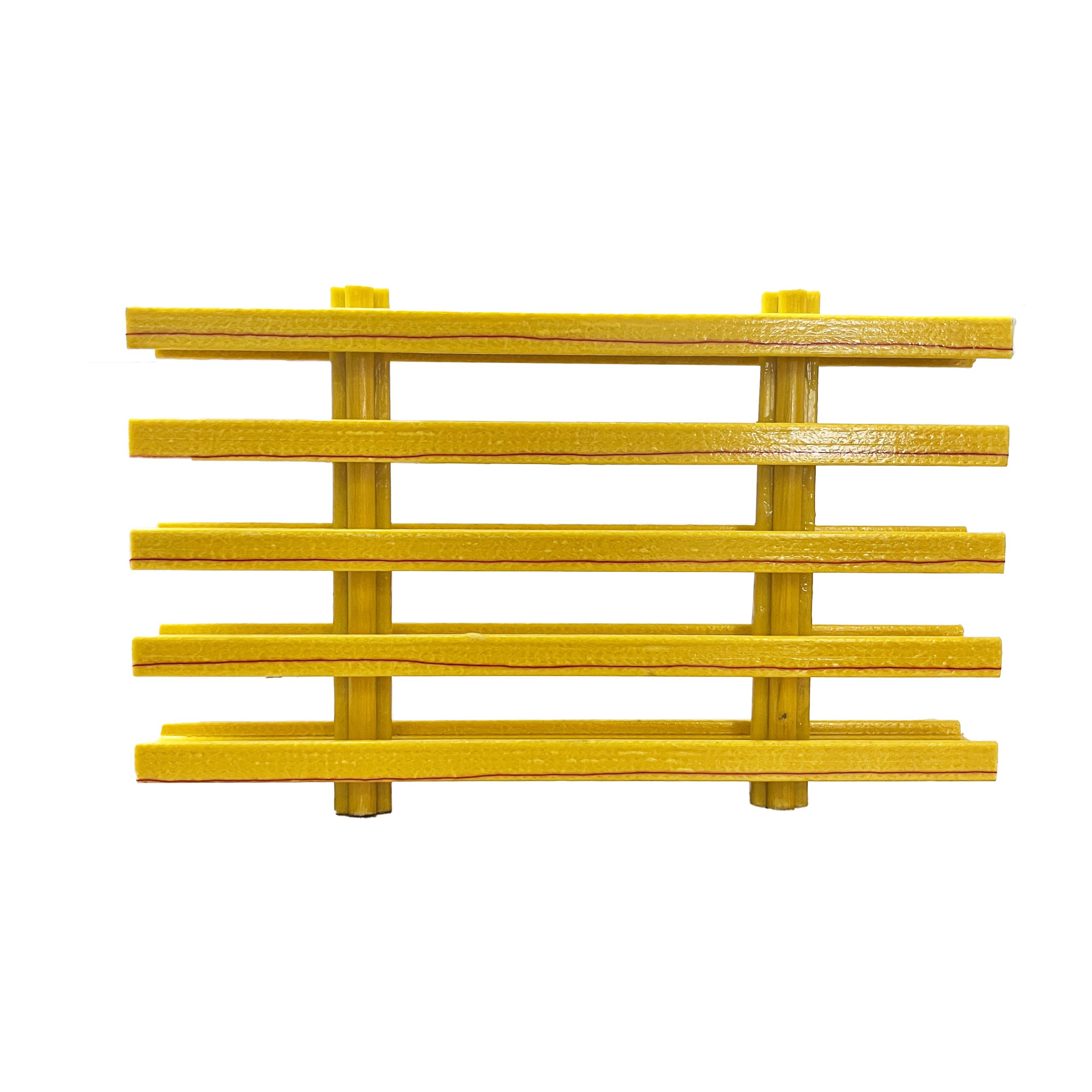

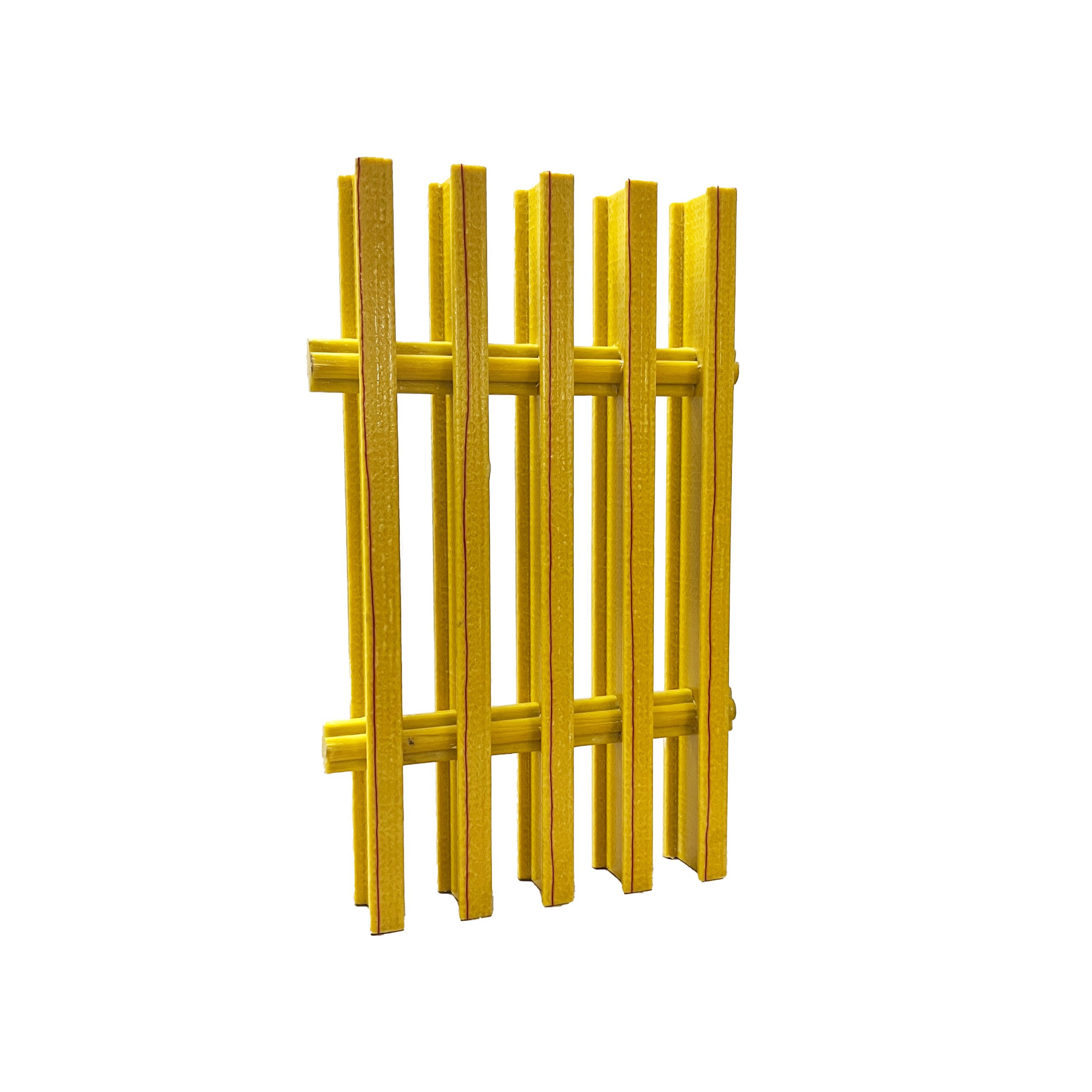

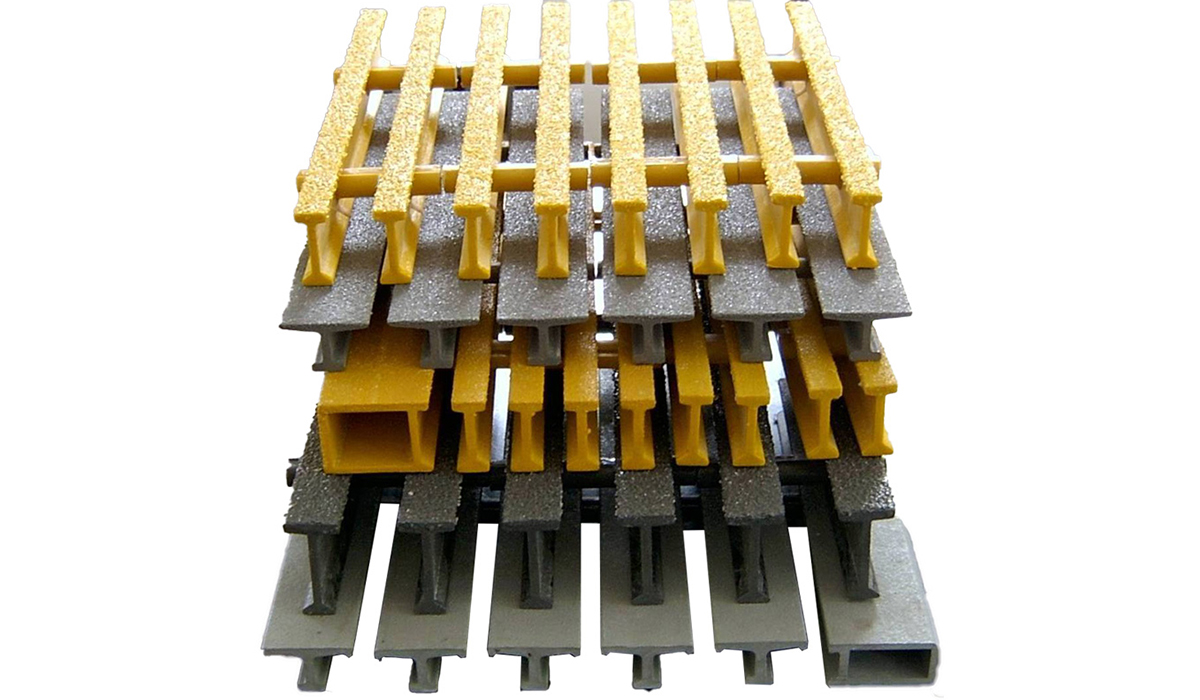

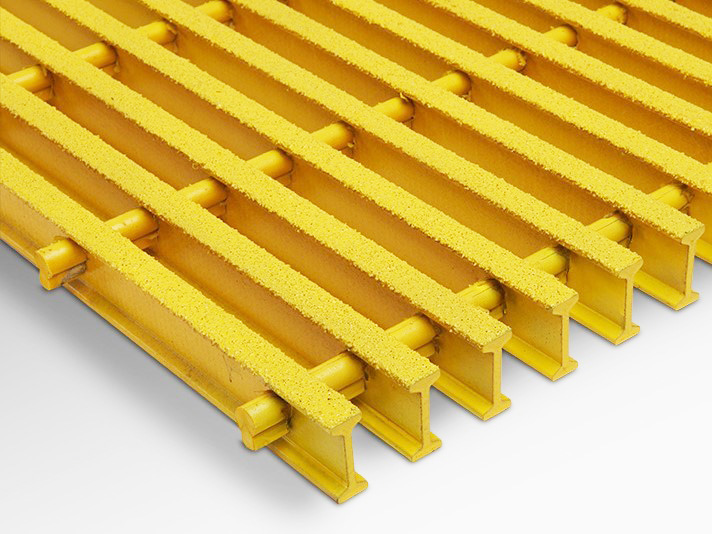

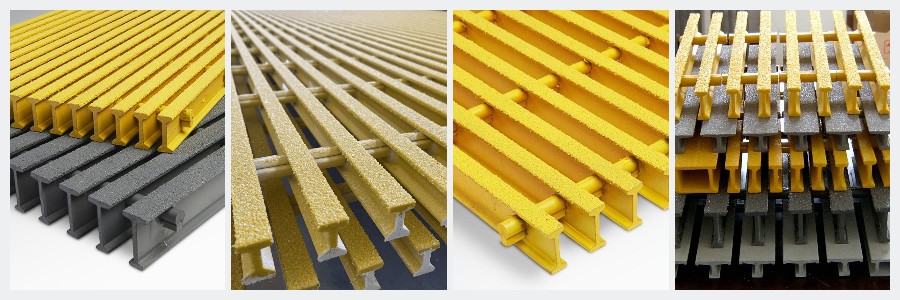

Pultruded grating is composed of a series of parallel bearing bars, kept in place by several perpendicular cross-rods. The closer the bars are placed together, the stronger the pultruded grating panel is. Pultruded Fiberglass Grating is high-strength grate that performs well in corrosive environments or where a lightweight grating is preferable. Fiberglass Grating pultrusions come in 3 types: I-Shape bars, T-Shape bars, and High-Load bars for Heavy-Duty Applications.

Product performance introduction

Pultruded FRP Grating

Pultruded Grating is manufactured by pultrusion process, where continuous fiberglass rovings and mats are drawn through rails, resin baths and pre-formers, then wrapped with a synthetic veil and pulled through a heated die. Fiberglass pultruded grating is uni-directional in strength and provides increased load capacity and very good levels of corrosion resistance. Large span area always need safe solution which could provide enough loading for various scenes. That’s why we produce kinds of pultruded gratings. Higher fiber volume and better unidirectional machinery properties than molded grating can make it work well under same clear span. Meanwhile, pultruded grating has all the advantages which molded grating has.

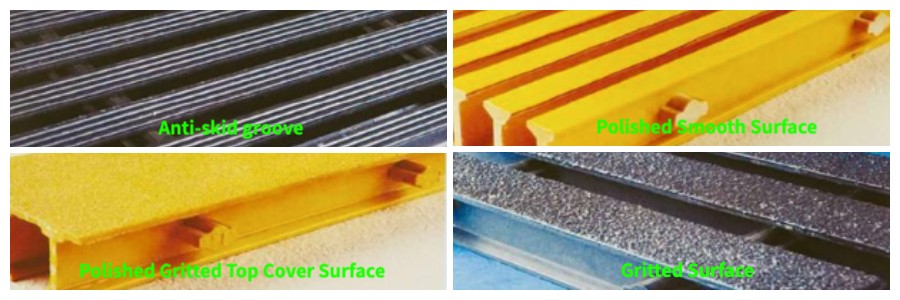

Pultrued Grating Surface:

- Anti-skid groove

- Polished Smooth Surface

- Gritted Top Cover

- Gritted Surface

Application

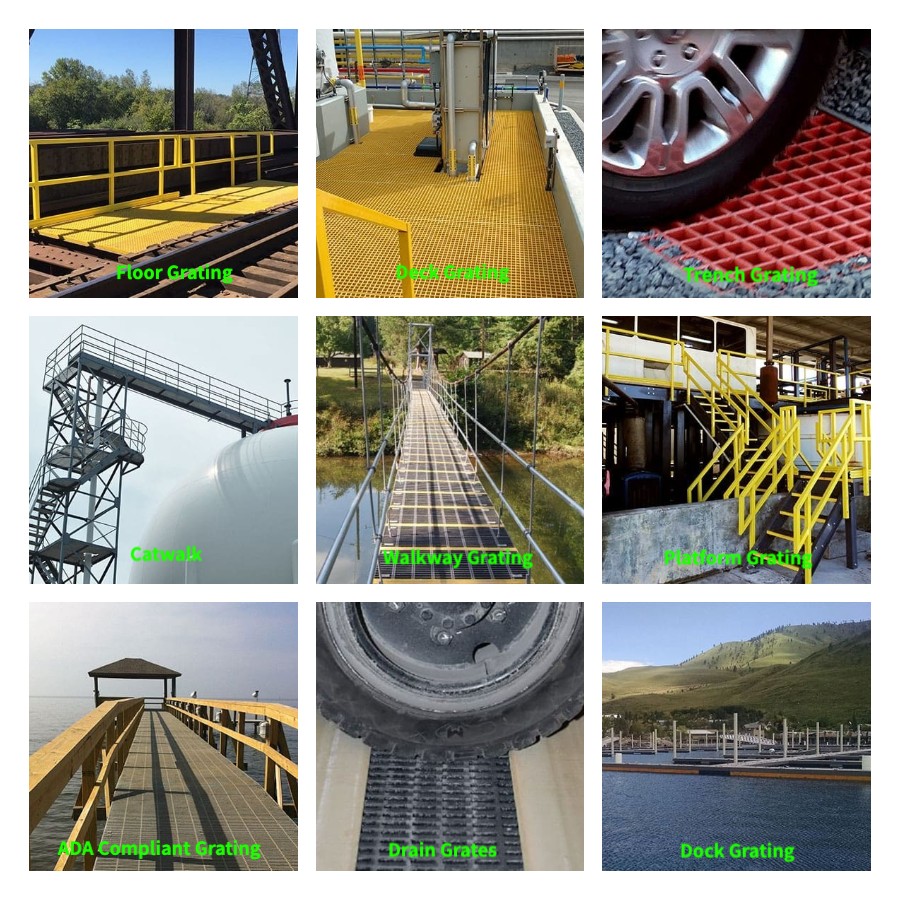

FRP gratings are usually used as floor grating, marina walkway, roof walkway, catwalk grating, work platforms, offshore platforms, decks, stair treads, fencing, tree guard, drain channel cover, ditch covers, etc.

And they are widely used in petroleum, water conservancy, textile printing and dyeing, food processing, electronics industry, sewage treatment, shipbuilding, civil construction, power engineering, power substations, and chemical industries.

To find the specification and more detailed properties of our FRP grating, please feel free to contact us.

Fiberglass gratings equipment

Fiberglass gratings equipment is mainly composed of four parts: the molded grating device, heating system, cooling system and ancillary equipment.

FRP molded grating devices can be adjusted according to product size and different specifications, but little change in the overall structure. It is composed of the following components: the cavity part, the roof system, cooling and heating system and basic part.

Heating is necessary to guarantee gratings shape. Unsaturated resin only cures polymerization under certain temperature and humidity, at the same time heating system can ensure the quality of the gratings. The system is composed of a heating pipe and connecting components, and the heating device consists of the external heating curing system.

Cooling is necessary to ensure the production of high speed, specific principles and similar to the heating system.

The heating system consists of heater, temperature controller, rehydration, pipeline, valve and pump system. The function of heating system is to provide heat

Cooling system consists of pipelines, valve and other components, the main role of equipment is to take the heat energy.

Packaging And Shipping

Please Feel Free To Contact Me

- Welcome to visit our factory

- Free Sample FRP Molded Grating Supplier

- JEC World 2024 – International Trade Administration

- Warehouse has sufficient supply

You can get quotation, technical advice and help around our fiberglass products.Thank you for submitting the inquiry, we will contact you soon!

Pultruded FRP Grating

Series :

Fiberglass Pultruded Grating >application

chemical industry,marine industry,offshore engineering,construction industry

Name :

Pultruded FRP Grating

Bearing Bars :

I-Shape bars, T-Shape bars, High-Load bars

Deep :

25mm/30mm/32mm/38mm/50mm

Resin :

Isophthalic Polyester Resin / Vinyl Ester Resin

FAQ

Q :

How is Pultruded FRP Grating made?

A :

When manufacturing, fiberglass rovings and mats are pulled through guide rails, then placed in a resin bath, then wrapped with surface yarn, and finally pulled through a heated mold to form the desired rod shape.

Q :

Which kind of pultruded fiberglass grating?

A :

I-Shape bars, T-Shape bars, and High-Load bars for Heavy-Duty Applications

Other related products