未加捻粗纱是一种重要的增强材料,主要用于…… 纤维缠绕 用于生产压力容器、化学品储罐、管道和风力涡轮机叶片等复合材料结构的工艺。与传统纱线或加捻粗纱不同,未加捻粗纱具有更优异的树脂浸渍性、更佳的纤维排列性和更优化的机械性能,使其成为高强度、耐腐蚀和轻质复合材料产品的关键组成部分。.

产品性能介绍

“未扭曲”一词指的是 缺乏刻意的曲折 在粗纱中,这种结构特性最大限度地减少了纤维之间的间隙,促进了纤维强度的充分发挥,从而实现了更好的纤维与树脂相互作用、更容易的浸渍和更均匀的应力分布。.

2. 纤维缠绕工艺概述

纤维缠绕是一种制造技术,它将浸渍了树脂的连续纤维丝缠绕在旋转的芯轴上。缠绕完成后,树脂固化(通常采用热固化),然后移除芯轴,即可得到中空复合材料部件。.

纤维缠绕的关键步骤:

-

光纤输送:未加捻的粗纱在受控张力下从纱架上拉出。.

-

树脂浸渍粗纱通过树脂槽或注射系统。.

-

芯轴绕线纤维以特定角度(环形、螺旋形、极形)缠绕在旋转的芯轴上。.

-

养护伤口部分采用加热或紫外线固化树脂。.

-

脱模:取出芯轴,修整复合材料部分。.

未加捻的粗纱尤其适合 由于其尺寸稳定性、一致的张力处理能力和优异的润湿性能,该工艺适用。.

3. 卷绕用无捻粗纱的产品特性

| 特征 | 好处 |

|---|---|

| 无扭曲 | 最大限度提高拉伸强度,最大限度减少丝材错位 |

| 可控线密度 | 确保卷绕过程中厚度和质量流量的一致性 |

| 极佳的湿润效果 | 促进纤维与树脂充分接触,改善界面粘合。 |

| 兼容尺寸 | 针对聚酯、乙烯基酯或环氧树脂体系进行化学定制 |

| 低静电产生 | 提高加工稳定性,减少飞絮或绒毛 |

| 高抗拉强度 | 适用于结构和承压应用 |

| 均匀分布 | 降低零件厚度和机械性能的变异性 |

| 优化卷绕 | 适用于高速绕线作业 |

4. 无捻粗纱在卷绕中的应用

4.1 压力容器

-

气体储存钢瓶(例如,压缩天然气、氢气)

-

灭火器

-

空气接收器

4.2 工业管道

-

耐化学腐蚀管道

-

污水管道

-

地下管道

4.3 储罐和筒仓

-

酸液储存罐

-

肥料罐

-

盐水箱和水箱

4.4 基础设施和能源

-

风力涡轮机叶片(翼梁帽)

-

复合型灯杆

-

电气设备外壳

4.5 航空航天与国防

-

火箭弹壳

-

结构壳

-

无人机用纤维缠绕外壳

5. 技术要求

用于卷绕的未加捻粗纱必须满足特定的机械和加工标准:

| 要求 | 描述 |

|---|---|

| 线密度(Tex) | 范围从 2400 到 9600 tex;根据卷绕速度和零件厚度选择。 |

| 水分含量 | <0.10% 可实现最佳树脂粘接并减少空隙形成 |

| 灯丝直径 | 13-24微米,通常均匀分布以确保强度一致 |

| 抗拉强度 | 大于 2000 MPa,符合承压标准 |

| 树脂相容性 | 尺寸必须与树脂类型(聚酯、环氧树脂、乙烯基酯)相匹配。 |

| 线轴设计 | 横移和张力设置与卷筒和卷绕装置相匹配 |

| 解旋行为 | 出线顺畅,几乎没有卡顿或断线 |

| 保质期 | 受控储存12-24个月 |

6. 技术数据表 (TDS)

产品名称用于长丝缠绕的未捻粗纱

玻璃类型:E玻璃

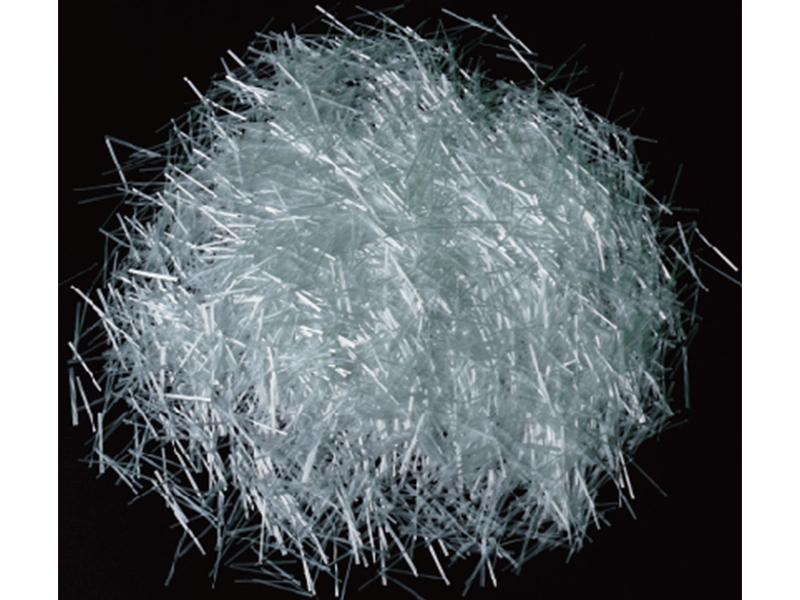

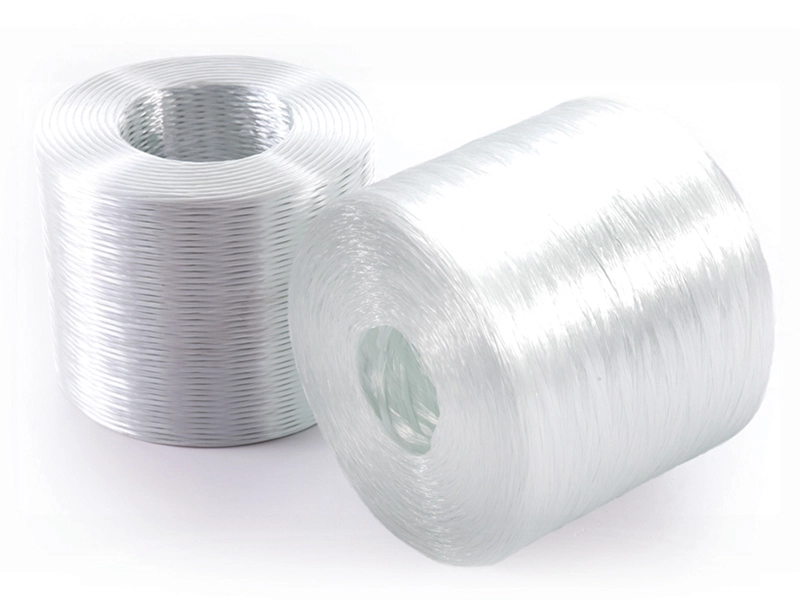

产品形式:连续的、未加捻的线股缠绕在圆柱形线轴上

6.1 物理性质

| 财产 | 典型值 | 测试方法 |

|---|---|---|

| 灯丝直径 | 13 – 24 微米 | ISO 1888 |

| 线密度(Tex) | 2400 / 4800 / 9600 特克斯 | ISO 1889 |

| 水分含量 | ≤ 0.10% | ISO 3344 |

| 点火损失 (LOI) | 0.80% – 1.30% | ISO 1887 |

| 密度 | 2.6 克/立方厘米 | ASTM D792 |

| 梭芯配重 | 15-25公斤 | 内部标准 |

| 包装尺寸 | 直径 270 毫米 × 高 260 毫米(可定制) | 制造商规格 |

| 颜色 | 自然白 | 目视检查 |

6.2 机械性能

| 财产 | 典型值 | 测试方法 |

|---|---|---|

| 抗拉强度 | ≥ 2300 兆帕 | ASTM D2343 |

| 拉伸模量 | ≥ 72 GPa | ASTM D2343 |

| 断裂伸长率 | 2.1% – 2.5% | ASTM D2343 |

| 兼容性(聚酯) | 出色的 | 潮湿程度评级(1-5) |

| 相容性(环氧树脂) | 出色的 | 潮湿程度评级(1-5) |

| 静电积累 | 微不足道 | 制造商测试 |

| 树脂浸润时间 | 不到 30 秒 | 视觉测试 |

7. 包装和物流

包装

-

缠绕在纸筒上的线轴(纸筒芯径 3 英寸)

-

用聚乙烯薄膜包裹,然后装入托盘

-

托盘:1.1米×1.1米,根据尺寸不同,可容纳48-64个线轴。

-

用弹力绷带包裹,并带有边角保护装置

标签

每个线轴包含:

-

产品代码和文本

-

毛重/净重

-

批号

-

生产日期

-

树脂相容性

8. 储存和保质期

-

温度15 – 35°C

-

湿度:≤ 65% RH

-

状况保持干燥,避免阳光直射和温度循环。

-

保质期:正常情况下可保存12个月;在温控仓库中可延长至24个月

9. 处理建议

| 过程参数 | 推荐 |

|---|---|

| 鱼篓设置 | 使用低摩擦陶瓷孔眼或滑轮 |

| 张力控制 | 每根线保持 1.0–1.8 N 的张力,且各线轴上的张力均匀。 |

| 浸渍 | 使用树脂浴或压力浸渍系统 |

| 树脂粘度 | 频率范围为 300–1000 cps,具体取决于光纤速度和零件尺寸。 |

| 芯轴转速 | 50 – 200 转/分(取决于应用) |

| 固化温度 | 80 – 160°C(取决于树脂) |

| 拉力速度 | 2 – 6 米/分钟 |

尖端

-

使用前务必将纤维在生产环境中进行 24 小时的调理。.

-

更换损坏的线轴,以防止线股不一致。.

-

在拼接或更换线轴时,确保纤维张力保持稳定。.

10. 健康与安全

防范措施

-

玻璃纤维粉尘可能会刺激眼睛、皮肤或呼吸系统。.

-

安装时请戴手套和护目镜。.

急救措施

-

接触眼睛:用清水冲洗 15 分钟。.

-

皮肤刺激:用肥皂和水清洗。.

-

吸入:移至空气新鲜处,必要时使用呼吸防护设备。.

有关完整的健康与安全指导,请参阅材料安全数据表 (MSDS)。.

11. 质量标准

| 认证 | 描述 |

|---|---|

| ISO 9001 | 质量管理体系 |

| ISO 14001 | 环境管理 |

| 符合REACH法规 | 化学品安全法规 |

| 符合RoHS标准 | 限制有害物质 |

| UL、ASTM 或 DIN 测试 | 可应要求提供 |

12. 环境因素

-

可回收性玻璃纤维边角料可以重新加工成填充材料。.

-

可持续发展惰性材料,无毒且耐用。.

-

遵守符合欧盟和美国的环境健康与安全法规。.

13. 自定义选项

制造商可根据以下条件提供定制化产品:

-

纺织/产量要求

-

树脂相容性(环氧树脂、聚酯树脂、乙烯基酯树脂、酚醛树脂)

-

丝状物直径优化

-

绕线机线轴尺寸定制

-

针对特殊应用(例如,抗紫外线、阻燃)定制的上浆化学

14. 制造商技术支持

顶级供应商提供:

-

现场工艺优化

-

为芯轴和树脂匹配提供工程支持

-

卷绕设计咨询

-

纤维测试和质量验证

15. 结论

用于卷绕的无捻粗纱是长丝卷绕工艺中的核心材料,因其纤维排列整齐、润湿性好、强度高和工艺稳定性强而备受青睐。其多功能性和优异的性能使其成为基础设施、航空航天、汽车和工业制造等领域先进复合材料应用的理想选择。.

凭借可定制选项、强大的质量控制和优异的机械性能,无捻粗纱可在任何高性能纤维缠绕应用中提高生产效率和长期可靠性。.

用于绕线的未捻粗纱

系列 :

玻璃纤维装配粗纱 >应用场景

汽车 / 消费品及商务设备 / 运动休闲 / 电气及电子产品 / 建筑及施工 / 基础设施

玻璃类型 :

乙

产品名称 :

用于绕线的未捻粗纱

常问问题

问:

你们是工厂吗?你们在哪里?

答 :

我们是 FRP 格栅和拉挤型材制造商,也是 FRP 纱线材料贸易商。我们是中国巨石公司最大的经销商。我们还销售多家 FRP 纱线制造商的产品。我们位于中国安徽省。

问:

建议询价时提供哪些信息?

答 :

1. 您需要哪种tex?2. 您将其用于什么用途?或者技术是编织、拉挤还是缠绕?3. 您需要多少数量?4. 您结合使用哪种树脂?聚酯树脂还是环氧树脂?5. 您需要FOB还是CIF价格,如果是CIF,请告诉我们您的港口。

问:

什么是最小起订量?

答 :

通常1吨

问:

包装和运输

答 :

普通包装:纸箱(包含在单价中) 特殊包装:需要根据实际情况收费。正常运输:您指定的货运代理。

问:

我什么时候可以报价?

答 :

我们通常在收到您的询问后 24 小时内报价。如果您非常急需价格,请致电我们或在您的电子邮件中告诉我们,以便我们可以优先回复您。

问:

你们如何收取样品费?

答 :

如果您需要我们库存的样品,我们可以免费提供给您,但您需要支付运费。如果您需要特殊尺寸,我们将收取样品制作费,该费用在您下订单时可退还。

问:

您的生产交货时间是多少?

答 :

如果我们有库存,可以在 7 天内交货;如果没有库存,需要 7~15 天!

其他相关产品