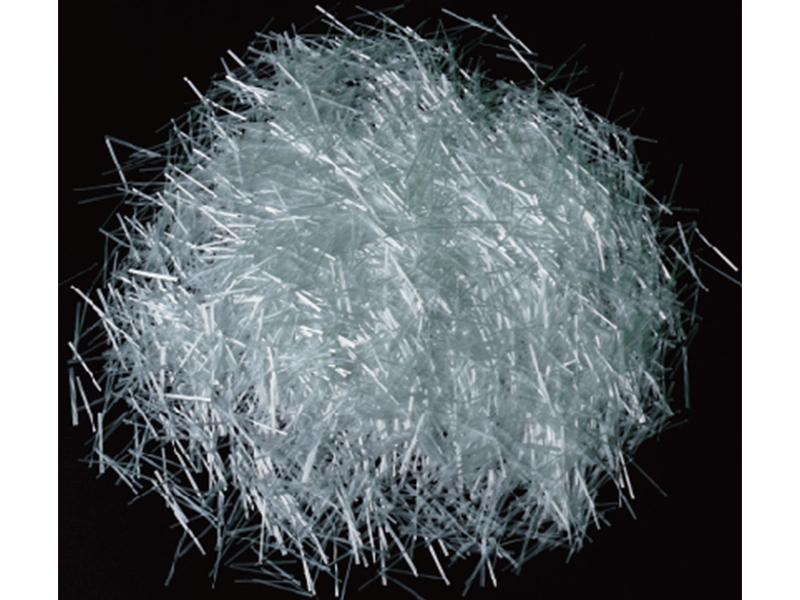

SMC漫游车 指的是一种专门设计用于……的短切玻璃纤维粗纱。 片状模塑料 表面模塑(SMC)工艺是一种大批量生产纤维增强塑料(FRP)部件的方法。SMC工艺常用于制造汽车车身面板、电气外壳、卫浴设备和工业外壳。.

产品性能介绍

SMC粗纱是由连续的玻璃纤维丝经切碎后均匀分散在树脂浆料中制成的半成品片材。这些片材随后被压缩成型为复杂的部件。.

SMC粗纱的选择对于确保最终产品的加工性能、机械性能和表面光洁度至关重要。SMC粗纱必须具备优异的短切性能、低静电、均匀分散性、良好的润湿性和与树脂基体的高度相容性。.

2. SMC工艺概述

SMC流程包括四个主要步骤:

-

复利将SMC粗纱切碎后铺展在载体薄膜上的树脂糊层上。再覆盖一层面膜,然后将片材压实至所需厚度。.

-

成熟将SMC片材轧制并老化(通常为24-72小时),以提高其粘度和成型一致性。.

-

成型将预先切割好的片材放入加热的压缩模具中,并在压力下固化。.

-

脱模经过短暂的固化过程后,将成型部件取出,并根据需要进行修整和精加工。.

3. SMC粗纱的主要特点

-

出色的切菜能力:切碎干净均匀,毛刺极少。.

-

快速润湿确保片材成型过程中树脂的有效浸渍。.

-

链完整性:在搅拌和压实过程中保持结构性能。.

-

低静压防止飞虫和线头缠绕,确保床单表面清洁。.

-

纤维长度分布均匀:对模制零件的均匀机械性能至关重要。.

-

兼容尺寸确保与聚酯或乙烯基酯树脂形成化学键合。.

-

高强度保留:可实现坚固、轻巧的最终组件。.

-

表面处理有助于在可见应用中实现 A 级表面光洁度。.

4. SMC粗纱的应用

4.1 汽车

-

引擎盖、行李箱盖、车顶面板

-

结构支撑,底盘护板

-

电动汽车电池外壳

4.2 电气与能源

-

变压器外壳

-

电表箱

-

电缆桥架

4.3 卫生洁具

-

浴缸、淋浴盘

-

洗脸盆支架

-

复合材质马桶座圈

4.4 建筑与基础设施

-

电线杆

-

井盖

-

装饰性建筑面板

4.5 工业设备

-

机器防护罩

-

泵壳

-

控制面板盒

5. SMC粗纱的技术要求

为了获得最佳性能,SMC 粗纱必须满足几个特定工艺标准:

| 要求 | 描述 |

|---|---|

| 德州或收益率 | 通常为 2400、4800、9600 tex。结构用 SMC 可使用更高 tex 的 tex 值。. |

| 水分含量 | <0.10% 以避免成型过程中产生孔隙。. |

| 尺寸内容 | 根据树脂体系的不同,数值为 1.2% – 2.0%。. |

| 股数 | 均匀的纤维分布对于防止缺陷至关重要。. |

| 切碎性 | 剪裁干净利落,几乎没有飞毛、绒毛或静电。. |

| 湿透时间 | 快速润湿,实现糊状物均匀吸收。. |

| 储存稳定性 | 在推荐条件下,保质期较长。. |

6. 技术数据表 (TDS)

产品名称:SMC 粗纱

玻璃类型:E玻璃(电气级)

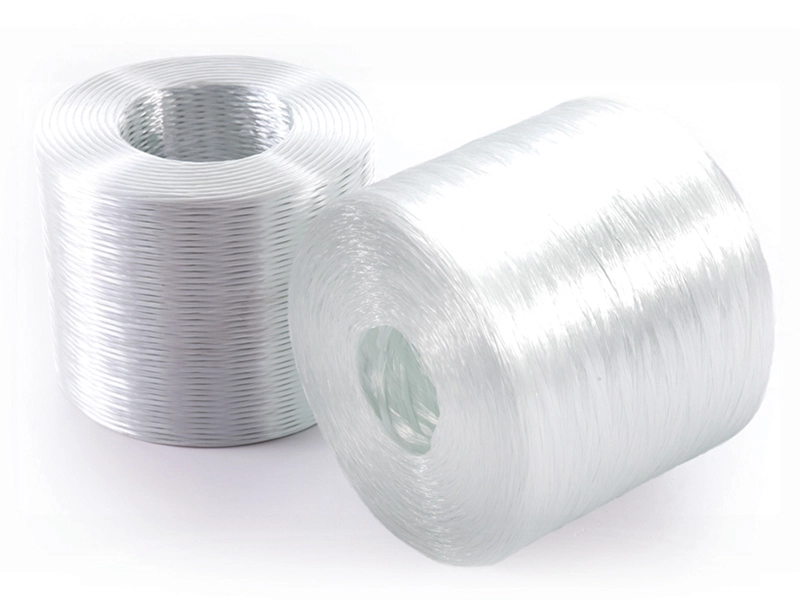

产品形式纸管上的连续纤维粗纱

可选尺寸:2400 / 4800 / 9600 特克斯

6.1 物理和化学性质

| 财产 | 典型值 | 测试方法 |

|---|---|---|

| 灯丝直径 | 13–24 微米 | ISO 1888 |

| 线密度(Tex) | 2400 / 4800 / 9600 | ISO 1889 |

| 水分含量(%) | ≤ 0.10 | ISO 3344 |

| 尺寸含量(%) | 1.2 – 2.0 | ISO 1887 |

| 点火损失 (%) | 1.5 ± 0.2 | ISO 1887 |

| 尺寸兼容性 | 聚酯、乙烯基酯、环氧树脂 | 内部标准 |

| 砍伐表演 | 极佳(干净,几乎没有杂音) | 内部方法 |

| 静电积累 | 微不足道 | 观察/评级 |

6.2 复合材料的力学性能

| 财产 | 典型值 | 测试方法 |

|---|---|---|

| 抗拉强度 | 大于 2000 兆帕 | ASTM D638 |

| 抗弯强度 | > 1000 兆帕 | ASTM D790 |

| 弯曲模量 | > 20 GPa | ASTM D790 |

| 冲击强度(缺口) | > 80 kJ/m² | ISO 179 |

| 密度 | 1.9 – 2.1 克/立方厘米 | ASTM D792 |

| 断裂伸长率 | 2.2 – 3.0% | ASTM D638 |

| 表面质量 | A级成绩可能达成 | 视觉 ASTM D2563 |

7. 包装和标签

包装

-

缠绕在圆柱形纸管上(纸芯直径3英寸)

-

卷材重量:每卷约15-25公斤(因特克斯而异)

-

分别装入PE袋,然后堆放在托盘上。

-

托盘尺寸:1.1米×1.1米;每托盘48-64卷

-

托盘用拉伸膜包裹,以增加稳定性和保护性。

标签

每卷都贴有标签:

-

产品名称和等级

-

德州/产量

-

净重

-

批号

-

生产日期

-

制造商和操作说明

8. 储存和保质期

-

存放于阴凉、干燥、通风良好的仓库中。

-

理想温度:15–35°C

-

相对湿度:≤ 65%

-

请将本品密封保存于原包装内直至使用。

-

避免阳光直射或高湿度环境

保质期自生产日期起,在标准储存条件下可保存 12 个月。.

9. 处理和加工指南

-

放松使用设计用于均匀分布张力的纱笼系统。.

-

切碎确保刀片锋利干净,以减少毛絮产生。.

-

片层形成:在混炼过程中保持树脂流动均匀和纤维分散均匀。.

-

成熟:留出适当的老化时间以稳定粘度。.

-

压缩成型使模具温度与树脂固化特性相匹配;仔细控制循环时间。.

10. 健康与安全

危险

SMC 粗纱无毒,但在加工过程中可能会对皮肤、眼睛和肺部造成机械刺激。.

防护措施

-

处理时请佩戴手套、护目镜和口罩。

-

在高产量加工区域使用除尘系统

-

接触后用肥皂和水清洗皮肤

急救

-

眼睛用水冲洗15分钟

-

皮肤冲洗干净并涂抹保湿霜

-

吸入到新鲜空气处去

更多详情请参阅材料安全数据表(MSDS)。.

11. 质量保证和标准

SMC 粗纱通常通过以下质量和合规性标准的认证:

-

ISO 9001:质量管理体系

-

ISO 14001:环境管理

-

REACH 和 RoHS 合规性

-

UL、ASTM 或 DIN 认证(可按需提供)

常规质量控制检查包括:

-

水分和粒度含量分析

-

拉伸试验

-

可切割性测试

-

树脂相容性检查

12. 产品定制与支持

领先的制造商提供以下定制服务:

-

德州范围调整

-

针对特殊树脂体系的特殊尺寸

-

表面处理方案

-

针对特定生产线的托盘优化

技术支持服务包括:

-

现场测试和故障排除

-

流程优化

-

复合材料设计咨询

-

模流模拟

13. 环境影响

-

可回收性SMC产生的玻璃纤维废料可以重新用于填料级应用。

-

可持续发展E玻璃无毒且化学性质稳定。

-

遵守产品符合包括RoHS、REACH和加州65号提案在内的全球环境法规。

14. 结论

SMC粗纱是一种高性能玻璃纤维增强产品,专为生产片状模塑料而设计,广泛应用于各个行业。它兼具优异的加工性能、机械强度和表面光洁度,使制造商能够生产出轻质、耐腐蚀、结构稳固且质量稳定的部件。.

SMC漫游车

系列 :

玻璃纤维装配粗纱 >应用场景

汽车 / 消费品及商务设备 / 运动休闲 / 电气及电子产品 / 建筑及施工 / 基础设施

玻璃类型 :

乙

产品名称 :

SMC漫游车

常问问题

问:

你们是工厂吗?你们在哪里?

答 :

我们是 FRP 格栅和拉挤型材制造商,也是 FRP 纱线材料贸易商。我们是中国巨石公司最大的经销商。我们还销售多家 FRP 纱线制造商的产品。我们位于中国安徽省。

问:

建议询价时提供哪些信息?

答 :

1. 您需要哪种tex?2. 您将其用于什么用途?或者技术是编织、拉挤还是缠绕?3. 您需要多少数量?4. 您结合使用哪种树脂?聚酯树脂还是环氧树脂?5. 您需要FOB还是CIF价格,如果是CIF,请告诉我们您的港口。

问:

什么是最小起订量?

答 :

通常1吨

问:

包装和运输

答 :

普通包装:纸箱(包含在单价中) 特殊包装:需要根据实际情况收费。正常运输:您指定的货运代理。

问:

我什么时候可以报价?

答 :

我们通常在收到您的询问后 24 小时内报价。如果您非常急需价格,请致电我们或在您的电子邮件中告诉我们,以便我们可以优先回复您。

问:

你们如何收取样品费?

答 :

如果您需要我们库存的样品,我们可以免费提供给您,但您需要支付运费。如果您需要特殊尺寸,我们将收取样品制作费,该费用在您下订单时可退还。

问:

您的生产交货时间是多少?

答 :

如果我们有库存,可以在 7 天内交货;如果没有库存,需要 7~15 天!

其他相关产品