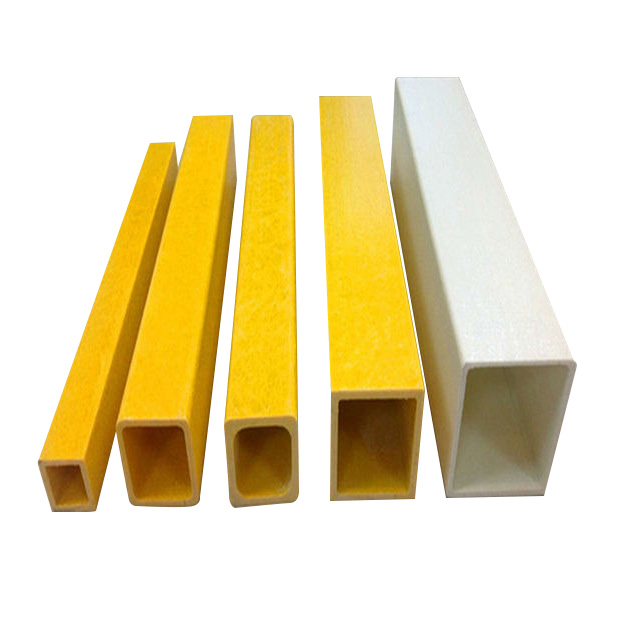

Fiberglass Reinforced Plastic Pultruded square tube is used as glass fiber reinforced materials, resin as bond, glass fiber cloth as parcel strengthening, through the thoroughly soak in the mould, heating, molding, curing, in the drawer of the traction control and form a new composite materials. The glass fiber content reaches as high as 65%, have a good physical and mechanical performance, high strength, big span in use, relatively appropriate. It is stronger than aluminum in the longitudinal direction of the profile.

Product performance introduction

|

|

|

|

|

|

|

|

FRP Square Tube Specification:

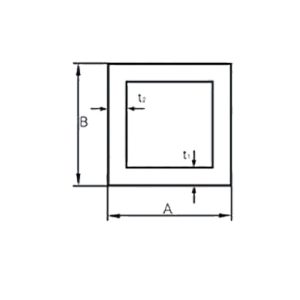

| View | Size A*B*t1*t2(MM) | Weight(G/M) |

|

30*30*3*3 | 648 |

| 40*40*3*3 | 888 | |

| 52.5*52.5*6*6 | 2232 | |

| 60*60*4*4 | 1600 |

The features of fiberglass pultruded square tubes are as follows:

- Strong corrosion resistance: The pultruded profile is immersed in 3% HCL water solution for 24 hours, and its hardness retention rate is 95%; after immersion in 3% NaCL water solution for 24 hours, its hardness retention rate is 89%.

- Low thermal insulation coefficient: the heat transfer coefficient of the pultruded profile is close to that of rigid PVC, and the thermal insulation coefficient of the single frame double glass thermal insulation window made of it is only 2.69W/(m2K).

- Adapt to environmental requirements: The production process selected for processing pultruded profiles has the characteristics of low noise, high efficiency, low power consumption, and low pollution.

- High heat distortion temperature: the heat distortion temperature of the pultruded profile is 186℃, it will not soften at high temperature, and will not be brittle at -60℃, ensuring normal use under various ambient temperatures.

- Low deformation rate: The length of the FRP pultruded profile after 1000h artificial accelerated aging changes to +0.03%, and the width change rate is -0.07%. Therefore, the shape and size of the product made of the pultruded profile can be kept stable for a long time.

- High strength: the tensile strength of the pultruded profile is 150-300MPa, the bending strength is 200-300MPa, and the bending strength preservation rate after 1000h artificial accelerated aging can reach 78%.

|

|

Application of the product

FRP Square Tube

Series :

Main Products >application

Chemical industry, Electric power, Marine aquaculture, Pharmaceutical, dye, Transportation industry, Sewage Processing, Food processing, Paper industry, Desulfurization and Environmental protection, such as: FRP grating platform, FRP operating platform, FRP guardrail, FRP ladder, Sports equipment, Garden tools, etc.

Brand name :

TFcomposite

Product name :

FRP Square Tube

Color :

Customized Color

FAQ

Q :

What are the advantages of pultruded tubes over other structural materials?

A :

The pultruded tube have a number of significant advantages over materials commonly used for structures including timber, steel, and aluminum in many structural, electrical, and environmental applications. Pultruded fiberglass is highly corrosion resistent, will not rot or decay and is not susceptible to insect attack. Unlike wood, fiberglass requires no environmentally unfriendly preservatives or repellants, does not absorb any significant amount of water and is consistent in strength and appearance piece-to-piece . Pultruded fiberglass is stronger, more rigid and lighter weight than structural timber, steel, and aluminum. Pultruded glass fiber reinforced structural shapes and plate are electrically and thermally non-conductive, impact resistant.

Q :

What is the pultrusion manufacturing process?

A :

Pultrusion is a manufacturing process for producing continuous lengths of FRP structural shapes. Raw materials include a liquid resin mixture (containing resin, fillers and specialized additives) and reinforcing fibers. The process involves pulling these raw materials (rather than pushing as is the case in extrusion) through a heated steel forming die using a continuous pulling device. The reinforcement materials are in continuous forms such as rolls of fiberglass mat or doffs of fiberglass roving. As the reinforcements are saturated with the resin mixture (“wet-out”) in the resin impregnator and pulled through the die, the gelation (or hardening) of the resin is initiated by the heat from the die and a rigid, cured profile is formed that corresponds to the shape of the die.

Other related products