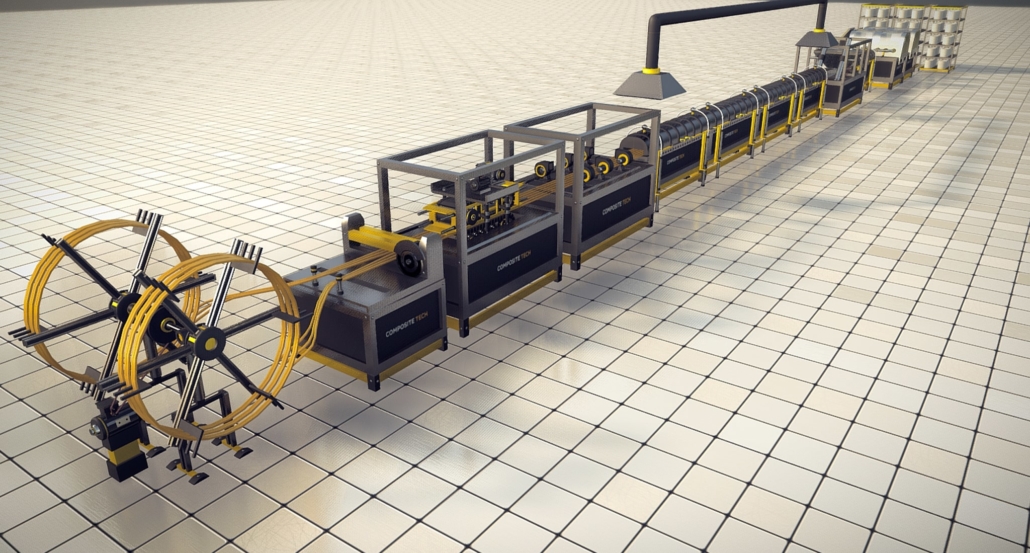

High-quality FRP rebar production line

Our FRP Rebar production line has been perfected over the course of the last 10 years and has now reached its peak product stage. Resultantly, we have achieved non-stop production process flow and made sure that it requires zero to none upkeep input, whilst producing a constantly high quality of end product at maximum output.

We manufacture 2 different FRP production lines:

- CT4 has simultaneous output of 4 bars

- CT6 has simultaneous output of 6 bars

Our equipment is designed to be reliable, highly productive and unique in the technology we utilise! All our developments and innovations are patented, which guarantees not only high effectiveness of your investment, but also a competition free market. Moreover, to ensure reliability of all production line modules we use only those components that have passed our rigorous tests and performance evaluations.

By acquiring Composite Tech FRP rebar production equipment, our clients also have following deliverables:

– Assistance in the selection of special premises

– Our specialists carry out installation of equipment and perform commissioning works

– Staff training

– Ongoing advice to your technical experts

Product performance introduction

Technical characteristics

Technical characteristics of the line for the production of composite reinforcement:

| Purpose: | manufacture of fiberglass or basalt fiber reinforcement |

| Diameter of products: | from 2 mm to 30 mm. |

| Voltage: | 380 V / 50 HZ |

| Power: | 26 kw |

| Line Performance: | 6-26 running meters per minute |

| Equipment Length: | 45m |

| Width: | 1.2m |

| Height: | 1.6m |

Depending on the configuration our production lines can be used to simultaneously produce either 4 (CT4) or 6 bars (CT6), significantly increasing productivity.

FRP rebar produced by our equipment has enhanced strength properties (rupture strength, breaking strength and tensile strength), which is appreciated by professional construction companies across the globe.

We have achieved such performance as a result of a very large amount of work done in collaboration with various universities and research centres that specialise in composite materials and advanced construction industry technologies.

GFRP Composite Rebar Crawler Type Pultrusion Machine/FRP Fiberglass Rebar Making Machine

| No | Name | Details |

| GFRP Rebar Making Machine | ||

| 1 | Haul off Way | Rubber Block/Belt |

| 2 | Motor | 2.2KW*2 |

| 3 | Speed mode | Frequency/Servo Control |

| 4 | Transfer method | Sprocket drive |

| 5 | Production Speed | 0.5 ~ 2m/mim |

| 6 | Clamping method | pneumatic |

| 7 | Applicable Products | Frp Screw Rod/Glass fiber reinforced ribs |

| 8 | Oven power | 16kw |

| 9 | Winding speed | 0-285rpm |

| 10 | Production diameter | 6-36mm |

| 11 | Total power | 35kw |

| 12 | Installation size | 30000*1600*1000 |

| 13 | Weight | 3.5tons |

Because this equipment is a customized product, the above parameters are for reference only, please contact us if you need precise details

This FRP Rebar Pultrusion Making Machine equipment is a special machine for producing glass fiber reinforced materials. It is mainly made of fiber materials as reinforcement materials, resin as the body, adding a certain amount of additives, and drying and curing fiber products at a certain temperature.

1. The FRP Rebar Making Equipment is composed of creel, dipping device, winding device, heating device, traction device, cutting device, electric cabinet and pneumatic system.

2. The winding device adopts flexible winding wire, which will not cut the surface fiber structure.

The 3 yarn content can reach 80%, which greatly improves the mechanical properties of the rod body and reduces the product cost.

4. Automatic cutting, automatic unloading, saving a lot of labor costs.

5. It has a pre-heating function, which improves the curing effect and can smoothly produce rods with a diameter of 25mm or more.

6. The degree of automation is extremely high. The material trough, the pressure rod, the winding, the drying tunnel, and the traction are pneumatically controlled. All operations can be completed by operating the buttons on the electric cabinet.

9. The dust collector protects the environment and the health of the operator.

10. It adopts a closed type, beautiful and generous, has a heat preservation effect, and does not affect the operation.

GFRP Rebar Making Machine

Series :

FRP Rebar And Rebar Machine >application

APPLICATION OF A COMPOSITE GRID AS A CLOTHING FOR ROADS.

FAQ

Other related products