Hand layup resin is a type of resin that is commonly used in the manufacturing of composite materials, such as fiberglass. It is a versatile and cost-effective material that can be easily applied by hand, making it ideal for small-scale production or repair work.

Product performance introduction

Hand layup resin typically consists of a liquid resin component and a hardener component that, when mixed together, undergo a chemical reaction that causes the resin to cure and harden. This process is known as polymerization, and it results in a strong and durable material that is resistant to corrosion, heat, and chemicals.

Hand layup resin can be used to create a wide range of products, including boat hulls, automotive parts, aerospace components, and even decorative items. It is often applied to a mold or substrate using a brush, roller, or spray gun, and can be reinforced with fiberglass, carbon fiber, or other materials to enhance its strength and stiffness.

Overall, hand layup resin is a versatile and reliable material that is widely used in the manufacturing industry for its ease of use, durability, and cost-effectiveness. Whether you are a hobbyist looking to create custom parts or a professional manufacturer in need of a reliable production material, hand layup resin is a great choice for a wide range of applications.

| Model | Type | 25℃ pa.s Viscosity |

Min Gel Time |

Non -volatile | MPa Tensile Strength |

Elongation | MPa Flexural Strength |

HDT ℃ | Application&Remarks |

| DC191 | DC | 0.20-0.45 | 6.0-12.0 | 68-74 | 58 | 2.9 | 93 | 85 | General FRP products and small pipes |

| 191 | PA | 0.25-0.45 | 9.0-17.0 | 61-70 | 60 | 3.5 | 112 | 70 | Highly applicable resin for General FRP products |

| 191P | PA | 0.25~0.45 | 14.0-20.0 | 61-67 | 70 | 3.5 | 112 | 68 | GP,accelerated resin for normal FRP products |

| 123TP | DCPD | 0.25-0.45 | 10.0-32.0 | 69-75 | 50 | 2 | 90 | 85 | With wax, accelerated and thixotropic for normal FRP products |

| 123 | PA | 0.35-0.45 | 15.0-60.0 | 55-64 | 62 | 2 | 120 | 65 | Universal accelereated and thixotropic resin for hand layup and sprayup FRP |

| 189 | PA | 0.25-0.45 | 10.5-21.5 | 59-65 | 65 | 4 | 298 | 57 | Boat building resin |

| 189TP | PA | 0.45-0.55 | 10.5-21.5 | 59-65 | 65 | 4 | 115 | 57 | Accelerated thixotropic resin for boat building |

| 196 | PA | 0.25-0.45 | 9.0-17.0 | 61-67 | 60 | 1.8 | 325 | 66 | Food grade container, pipes and other FRP products |

| 390 | PA | 0.15-0.22 | 8.0-20.0 | 58-62 | 42 | 2.4 | 75 | 61.2 | Specially suitable for reinforce acrylic and bathtubs. |

| 1045MT | PA | 0.30-0.50 | 15.0-45.0 | 57-63 | 62 | 2 | 120 | 65 | Acclerated thixotropic resin for mannequin and normal FRP products |

| 199 | ISPA | 0.35-0.65 | 10.0-16.0 | 56-64 | 55 | 1.8 | 90 | 120 | Resist to 120℃, suitable for FRP require heat-resistant property |

| 199X | PA | 0.35-0.65 | 13.0-19.0 | 56-62 | 60 | 2 | 90 | 115 | Resist to 115℃, suitable for FRP require heat-resistant property |

| 3301 | ABPA | 0.35-0.58 | 5.8-10.7 | 56-62 | 55 | 2 | 105 | 100 | Resist to 115℃, suitable for FRP require heat-resistant property |

| 197 | ABPA | 0.40-0.50 | 10.0-25.0 | 47-53 | 60 | 2 | 90 | 115 | CEE type, excellent corrosion resistance |

Here are some key points about the application of hand layup resins:

-

Resin Preparation:

- The resin and any necessary hardeners or additives need to be thoroughly mixed according to the manufacturer’s instructions. This ensures proper curing and performance of the resin.

- The resin viscosity may need to be adjusted by adding solvents or thinners to achieve the desired application consistency.

- Proper safety equipment, such as gloves and respirators, should be used when handling the resin.

-

Mold Preparation:

- The mold surface should be clean, dry, and properly prepared with a release agent to facilitate part removal after curing.

- Any reinforcement materials, such as fiberglass or carbon fiber, should be carefully positioned and secured in the mold.

-

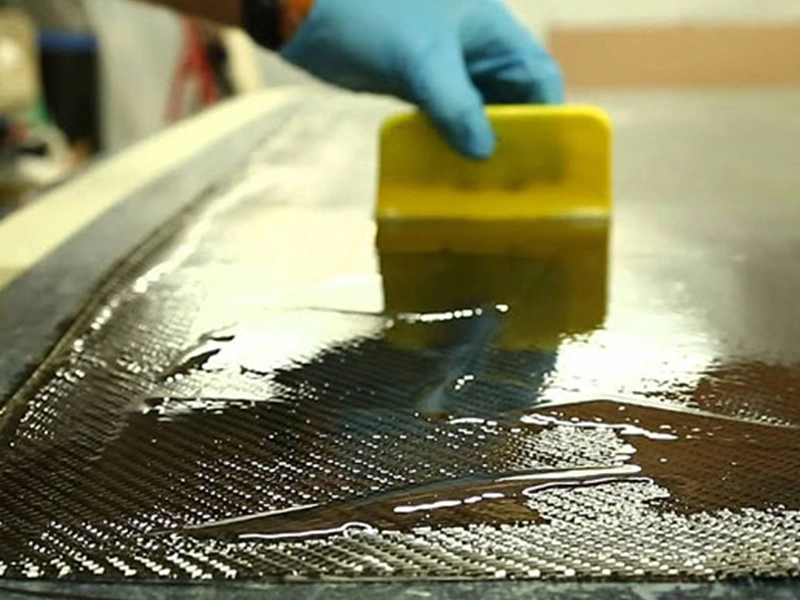

Resin Application:

- The resin is typically applied to the reinforcement materials using a brush, roller, or spatula. This ensures even coverage and impregnation of the fibers.

- The resin should be applied in thin, even layers, allowing each layer to partially cure before applying the next.

- Care should be taken to avoid air entrapment and ensure complete wetting of the reinforcement materials.

-

Curing:

- The curing process should be carried out according to the resin manufacturer’s recommendations, which may include specific temperature and humidity conditions.

- Adequate ventilation should be provided during the curing process to allow for the release of any volatile organic compounds (VOCs).

- The cured part should be inspected for any defects, such as voids, delaminations, or surface irregularities, before proceeding with further processing or use.

-

Post-Curing:

- Some hand layup resins may require a post-curing step to fully develop their mechanical and chemical properties.

- Post-curing is typically done by exposing the cured part to elevated temperatures for a specific duration, as recommended by the resin manufacturer.

-

Cleanup and Disposal:

- Any unused resin and associated materials should be properly disposed of according to local environmental regulations.

- Cleanup of tools and equipment should be done using the appropriate solvents or cleaners recommended by the resin manufacturer.

Proper application and curing of hand layup resins are crucial to ensuring the quality and performance of the final composite part. Following the resin manufacturer’s instructions and maintaining good safety practices are essential for successful hand layup projects.

Here are some frequently asked questions (FAQs) about hand layup resins:

-

What are the common types of resins used in hand layup?

- The most common resins used in hand layup are thermoset resins, such as polyester, vinyl ester, and epoxy. These resins provide the necessary mechanical properties, chemical resistance, and ease of application for hand layup composites.

-

What are the key properties of hand layup resins?

- Viscosity: The resin should have a suitable viscosity that allows for easy impregnation and wetting of the reinforcement fibers during the hand layup process.

- Curing characteristics: The resin should have a curing time that provides enough working time for the hand layup process, while also curing at a reasonable rate to allow for efficient production.

- Mechanical properties: The cured resin should provide the necessary tensile, flexural, and compressive strength to meet the requirements of the application.

- Chemical resistance: The resin should be resistant to the chemicals, solvents, and environmental conditions the composite part will be exposed to.

- Ease of use: The resin should be easy to mix, apply, and work with during the hand layup process.

-

How do hand layup resins differ from other composite resins?

- Hand layup resins typically have a higher viscosity compared to resins used in processes like infusion or pultrusion. This higher viscosity helps the resin remain in place on the reinforcement fibers during the manual layup process.

- Hand layup resins often have a longer working time and slower curing characteristics to allow the fabricator sufficient time to properly position and impregnate the reinforcement materials.

-

What are the common reinforcement materials used with hand layup resins?

- The most common reinforcement materials used in hand layup are woven and non-woven fabrics, such as fiberglass, carbon fiber, and aramid fiber. These reinforcements provide the necessary strength and stiffness to the composite parts.

-

How are hand layup resins formulated and customized?

- Hand layup resin formulations are developed by resin manufacturers to meet the specific requirements of the application, such as mechanical properties, chemical resistance, and processing characteristics.

- Additives, such as fillers, thixotropic agents, and UV stabilizers, may be incorporated into the resin formulation to enhance specific properties or processing characteristics.

- Customization of the resin formulation can be done to optimize the viscosity, curing behavior, and other properties for the specific hand layup process and part requirements.

-

What are the key considerations in selecting a hand layup resin?

- Viscosity: The resin should have a viscosity that allows for easy impregnation of the reinforcement fibers during the hand layup process.

- Curing characteristics: The resin should have a working time and curing rate that provides sufficient time for the fabricator to properly lay up the composite.

- Mechanical properties: The cured resin should meet the strength and stiffness requirements of the application.

- Chemical resistance: The resin should be resistant to the chemicals, solvents, and environmental conditions the composite part will be exposed to.

- Ease of use: The resin should be easy to mix, apply, and work with during the hand layup process.

Hand Layup Resin

Series :

Unsaturated Polyester Resin >application

Hand lay-up is the most common and least expensive open-molding method because it requires the least amount of equipment.

Brand name :

Hand Layup Resin

FAQ

Q :

Do you sell fiberglass and resin?

A :

Yes!

Other related products