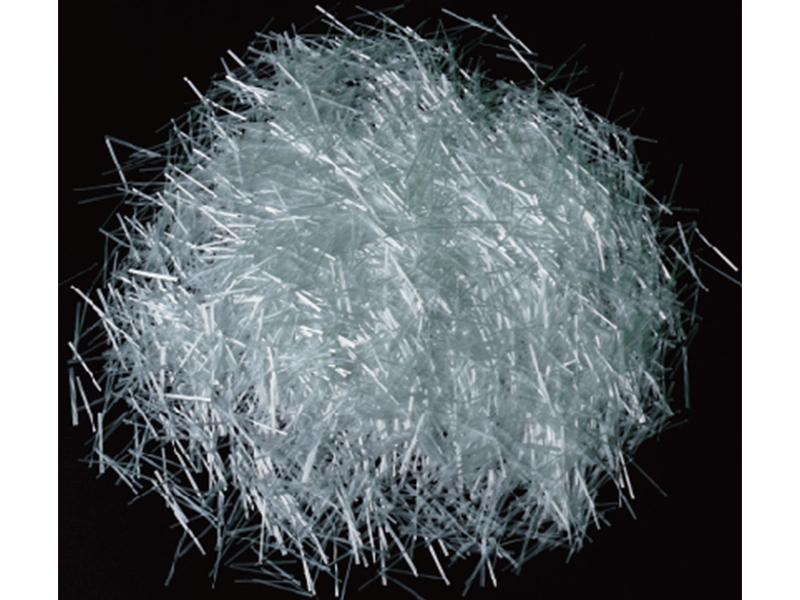

로빙 스프레이, 또한 ~로 알려짐 잘게 자른 스트랜드 로빙, 로빙은 주로 스프레이 성형 공정에 사용되는 유리 섬유 강화재입니다. 전기 등급 유리(E-glass) 필라멘트가 연속적으로 연결되어 있으며, 폴리에스터, 비닐 에스터, 에폭시 또는 폴리우레탄 수지와 호환되는 사이징제로 코팅되어 있습니다. 이 유형의 로빙은 개방형 금형 스프레이 성형 공정에 사용하도록 설계되었으며, 이 공정에서는 로빙을 잘게 자른 후 스프레이 건을 사용하여 수지와 동시에 도포합니다.

제품 성능 소개

스프레이 로빙은 빠른 습윤성, 우수한 분산성, 수지 매트릭스에 대한 강력한 접착력으로 잘 알려져 있어 욕조, 보트, 자동차 부품, 저장 탱크 및 다양한 건축 자재와 같은 복합 제품 제작에 이상적인 보강재입니다.

2. 제품 특징 및 특성

-

호환성스프레이 로빙은 다양한 수지와의 호환성을 보장하기 위해 여러 가지 크기 조절 시스템으로 제공됩니다.

-

불포화 폴리에스터(UP)

-

비닐 에스테르(VE)

-

에폭시(EP)

-

페놀 및 폴리우레탄 시스템

-

-

균등 분산균일한 절단과 손쉬운 분산을 제공하고 보풀 발생을 최소화하도록 설계되었습니다.

-

높은 청렴도가공 과정에서 우수한 가닥 무결성과 보풀 발생 및 정전기 축적 방지 기능을 제공합니다.

-

빠른 발수: 수지 함침 속도를 높여 생산 효율을 향상시키고 공기 혼입을 줄입니다.

-

뛰어난 기계적 특성완성품에 높은 인장 강도, 굴곡 강도 및 충격 강도를 제공합니다.

-

부식 저항모든 유리섬유 제품과 마찬가지로 스프레이 로빙은 화학적 부식에 대한 저항성이 매우 높아 해양 및 화학 산업 분야에 적합합니다.

-

치수 안정성열과 습기에 노출되어도 수축, 뒤틀림 또는 변형이 발생하지 않습니다.

3. 응용 프로그램

스프레이 로빙은 다양한 산업 분야에서 널리 사용됩니다. 주요 적용 분야는 다음과 같습니다.

3.1 해양 산업

-

보트 선체와 갑판

-

카누와 카약

-

개인용 수상 오토바이 부품

3.2 위생 도기

-

욕조

-

샤워실

-

세면대

-

물탱크

3.3 자동차

-

차체 패널

-

후드

-

내부 구성 요소

-

트럭 부품

3.4 건설 및 기반 시설

-

벽 패널

-

골판지 시트

-

지붕 구성 요소

-

배관 라이너 및 커버

3.5 산업 장비

-

화학물질 저장탱크

-

덕트 및 후드

-

기계 하우징

3.6 레크리에이션 용품

-

서핑보드

-

워터 슬라이드

-

놀이터 장비

4. 제조 공정: 스프레이업 기술

로빙 스프레이는 주로 다음을 사용하여 적용됩니다. 분무 기법, 널리 사용되는 개방형 금형 공정입니다. 작동 방식은 다음과 같습니다.

4.1 장비

-

초퍼가 장착된 스프레이 건

-

수지 저장조 및 펌프 시스템

-

압축 공기 공급원

-

촉매 주입 시스템

-

개방형 금형(일반적으로 젤 코팅 처리됨)

4.2 처리 단계

-

금형 준비금형 이형제와 젤코트를 도포합니다.

-

자르기 및 분무로빙은 분쇄기를 통과하면서 수지와 촉매가 동시에 분사됩니다.

-

롤링 및 다짐롤러를 사용하여 라미네이트를 압축하고 기포를 제거하며 균일한 두께를 확보합니다.

-

경화: 해당 부품은 수지 시스템에 따라 실온 또는 열을 가해 경화시킵니다.

-

탈형 및 다듬기완전히 경화되면 부품을 금형에서 꺼내 필요에 따라 다듬습니다.

5. 스프레이 로빙의 장점

-

사용 편의성: 절단 및 적층 공정을 통합하여 보강 공정을 간소화합니다.

-

비용 효율적수작업 적층 방식에 비해 노동력과 시간을 절감합니다.

-

높은 생산성적층 구조를 더 빠르게 구축할 수 있도록 해줍니다.

-

디자인 유연성복잡한 형태와 넓은 표면적에 적합합니다.

-

수지 제어 기능 향상최적화된 수지 대 유리 섬유 비율은 부품 성능 향상 및 무게 최적화에 기여합니다.

-

표면 마감 품질: 젤코트와 호환되어 뛰어난 표면 미관을 제공합니다.

6. 기술 데이터 시트(TDS)

제품 이름: 스프레이 로빙

유리 종류: E-유리

형태스프레이 도포용 연속 가닥 로빙

6.1 물리적 성질

| 재산 | 일반적인 값 |

|---|---|

| 필라멘트 직경 | 13~17 마이크론 |

| 선밀도(텍스) | 2400, 3000, 4800 |

| 수분 함량 | ≤ 0.10% |

| 크기 내용 | 0.8–1.2% (호환성에 따라 다름) |

| 절단 가능성 | 훌륭한 |

| 분산 | 제복 |

| 퍼즈 레벨 | 매우 낮음 |

6.2 기계적 특성

| 재산 | 일반적인 값 |

|---|---|

| 인장강도 | > 1800 MPa |

| 인장 탄성 계수 | > 72 GPa |

| 굽힘 강도 | > 1200 MPa (복합재료 기준) |

| 충격 저항 | 높은 |

| 파단 시 신장 | 2.5–3.0% |

6.3 호환성 옵션

| 수지 유형 | 호환 사이즈 코드 |

|---|---|

| 불포화 폴리에스터 | UP 시리즈 |

| 비닐 에스테르 | VE 시리즈 |

| 에폭시 | EP 시리즈 |

| 폴리우레탄 | PU 시리즈 |

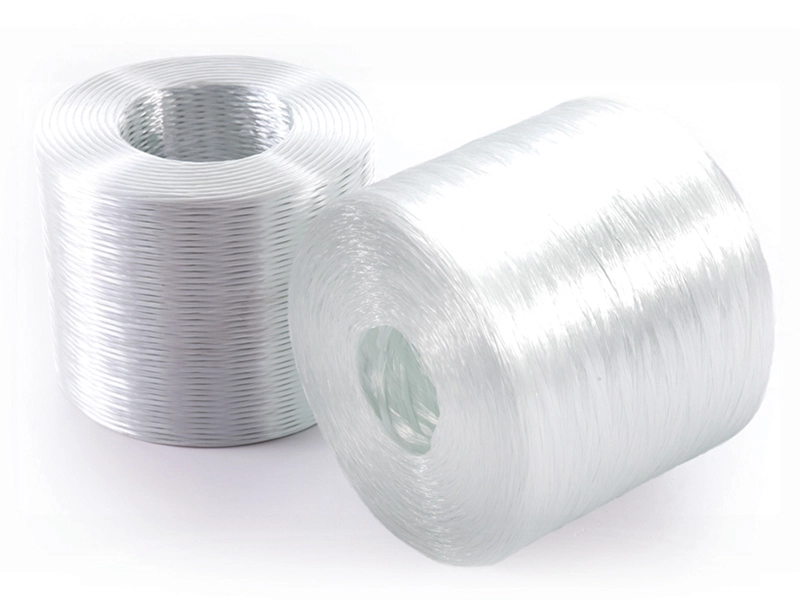

7. 포장 및 보관

포장

-

로빙은 원통형 판지 실패 또는 팬케이크에 감겨 있습니다.

-

각 롤의 무게는 질감에 따라 일반적으로 15~25kg입니다.

-

롤 형태의 제품은 수축 포장되어 골판지 상자나 팔레트에 포장됩니다.

-

팔레트는 습기 방지를 위해 스트레치 랩으로 포장됩니다.

저장

-

건조하고 서늘하며 통풍이 잘 되는 곳에 보관하십시오.

-

권장 온도: 15~35°C

-

상대 습도: < 65%

-

직사광선과 습기와의 접촉을 피하십시오.

유통기한최적의 조건에서 보관할 경우 제조일로부터 12개월까지 사용 가능합니다.

8. 취급 및 처리 지침

-

긴장 풀기장력을 유지하고 엉킴이나 보풀 발생을 방지하려면 크릴 시스템을 사용하십시오.

-

절단균일한 섬유 길이를 유지하려면 분쇄기 날이 날카로운지 확인하십시오.

-

기압스프레이 건의 공기압을 최적화하여 균일한 분사 패턴을 확보하십시오.

-

롤러 도포도막을 고르게 다지고 갇힌 공기를 제거하려면 분사 직후 롤러를 사용하십시오.

9. 안전 및 환경 정보

보건 및 안전

-

분무형 로빙은 정상적인 조건에서는 무해한 제품입니다.

-

취급 과정에서 피부, 눈, 호흡기에 기계적 자극이 발생할 수 있습니다.

-

다음과 같은 개인 보호 장비(PPE)를 사용하십시오.

-

장갑

-

고글

-

방진 마스크 또는 호흡기

-

응급 처치 조치

-

피부 접촉비누와 물로 씻으세요.

-

눈맞춤물로 깨끗이 헹구세요.

-

흡입신선한 공기가 있는 곳으로 이동하시고, 증상이 지속되면 의사의 진료를 받으십시오.

환경적 영향

-

일반적인 폐기 조건에서 무독성 및 무반응성입니다.

-

산업용 유리섬유 제품에 대한 환경 규정을 준수합니다.

-

일부 공정에서는 재활용이 가능하며, 현지 법규에 따라 안전하게 매립할 수 있습니다.

10. 맞춤 설정 및 기술 지원

제조업체는 특정 생산 요구 사항에 맞춰 맞춤형 스프레이 로빙을 제공하는 경우가 많습니다. 옵션은 다음과 같습니다.

-

사용자 지정 텍스트 값

-

특수 수지용 특수 사이징제

-

식별을 위한 색상 코드 또는 추적 필라멘트

-

친환경 또는 저배출 제형

기술 지원은 일반적으로 스프레이 공정 매개변수를 최적화하고 부품 품질을 향상시키는 데 도움을 주기 위해 제공되며, 다음과 같은 서비스가 포함됩니다.

-

현장 기술 컨설팅

-

분무 장비 교정

-

결함 분석 및 문제 해결

-

모범 사례에 대한 교육 및 훈련

11. 결론

스프레이 로빙은 복합재 산업에서 없어서는 안 될 필수 소재로, 사용 편의성, 다용도성 및 우수한 성능으로 인정받고 있습니다. 보트, 욕조, 자동차 부품 또는 건축 패널 등 어떤 제품을 제조하든 스프레이 로빙은 복잡한 형상과 생산 환경에 적응할 수 있는 비용 효율적이고 고강도의 보강 솔루션을 제공합니다.

제조업체는 적절한 텍스처, 사이징 및 스프레이 매개변수를 선택함으로써 내구성이 뛰어나고 고품질의 복합 부품을 생산하는 동시에 생산성을 최적화할 수 있습니다. 사이징 화학 및 적용 방법의 발전으로 스프레이 로빙 기술은 지속적으로 발전하여 현대 복합재 응용 분야에 더욱 향상된 성능, 호환성 및 지속 가능성을 제공하고 있습니다.

로빙 스프레이

시리즈 :

유리 섬유 조립 로빙 >애플리케이션

자동차 / 소비재 및 업무용 장비 / 스포츠 및 레저 / 전기전자 / 건축 및 건설 / 인프라

유리 종류 :

이자형

사이징 유형:

실란

일반적인 필라멘트 직경(μm):

13

일반적인 선형 밀도(tex):

2000

예 :

EDR13-2000-910A

자주하는 질문

질문 :

공장이세요? 당신은 어디 어디에 있습니까?

ㅏ :

우리는 FRP 격자 및 인발 성형 프로파일 제조업체, FRP 원사 재료 상인입니다. 우리는 중국 Jushi Co.의 최대 유통업체입니다. 또한 여러 FRP 원사 제조업체의 제품을 판매합니다. 우리는 중국 안후이에 있습니다.

질문 :

문의 시 어떤 정보를 추천하시나요?

ㅏ :

1. 어떤 텍스트가 필요합니까? 2. 어떤 용도로 사용하시나요? 아니면 기술이 직조, 인발 또는 와인딩입니까? 3. 수량은 얼마나 필요합니까? 4. 어떤 레진을 조합하나요? 폴리에스터 수지인가, 에폭시 수지인가? 5. FOB 또는 CIF 가격이 필요합니까? CIF인 경우 포트를 알려주십시오.

질문 :

MOQ는 무엇입니까?

ㅏ :

보통 1톤

질문 :

패키지 및 배송

ㅏ :

일반 패키지: 판지(단위 가격에 포함됨) 특수 패키지: 실제 상황에 따라 충전해야 합니다. 일반 배송: 귀하가 지정한 화물 운송.

질문 :

언제 제안할 수 있습니까?

ㅏ :

우리는 일반적으로 귀하의 문의를 받은 후 24시간 이내에 인용합니다. 당신이 가격을 얻기 위해 매우 긴급한 경우 pls는 저희에게 전화하거나 귀하의 이메일로 알려주십시오. 그래야 우리가 당신에게 우선 순위를 회신할 수 있습니다.

질문 :

샘플 비용은 어떻게 청구하나요?

ㅏ :

당사 재고에서 샘플이 필요한 경우 무료로 제공할 수 있지만 운임을 지불해야 합니다. 특별한 크기가 필요한 경우 주문할 때 환불 가능한 샘플 제작 수수료를 청구합니다.

질문 :

생산을 위한 당신의 배달 시간은 무엇입니까?

ㅏ :

재고가 있는 경우 7일 이내에 배송할 수 있습니다. 재고가 없는 경우 7~15일 소요됩니다!

기타 관련 제품