Project Specification

Location: Canada

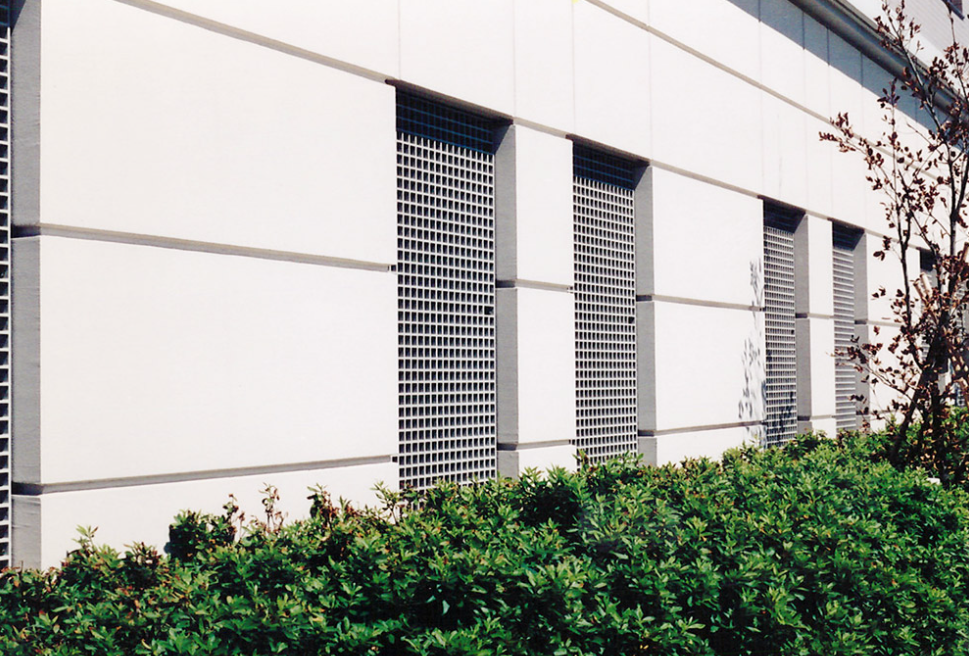

Application: Shading for student dormitory building

Product: Fibreglass Grating

Overview: A Canadian construction company took over a student housing redevelopment project at a university in Columbia.

A Canadian construction company took over the redevelopment of a student dormitory at a university in Columbia. The project consisted of retrofitting the student dormitories with sunshades to give the building a unique urban look. The panels protect the dormitories from the sun, keep the building cool, and act as a protective barrier.

Problem

Initially, the construction company wanted to use coated aluminium mesh panels; however, the saline environment would corrode the aluminium as the application was very close to saline soil. However, the saline environment would corrode the aluminium panels as the building is very close to the ocean. The main objectives of the project were aesthetics, sustainability and convenience, which were also the construction company’s requirements for Tianfu New Material’s grids.

Therefore, the engineers and foreign trade sales managers of Tianfu New Material had to ensure that the products used in this application met the following requirements:

— Corrosion resistance – These products had to be corrosion resistant because of the building’s proximity to the ocean (highly corrosive salt air environment).

– UV resistance – it is important to use grating with maximum UV resistance to prevent the grating from deteriorating in a wet environment.

– Low installation costs – The application was on a six-storey building; the client wanted to be able to complete the installation without any obstacles.

— Low maintenance – The company responsible for the project used the word “long-term” when describing the material he envisioned. It could be used for a long time without maintenance.

Solution

Skyfoam’s Foreign Trade Sales Manager had previously worked with the construction company on a similar project. After revisiting the site and understanding the application conditions, the construction company felt that FRP grating was the ideal choice for this project. Not because they had a good experience with Tianfu New Material in the past, but because of the aesthetics and performance of the product. FRP grating performs in this environment. It enhances the visual appeal of the building and fulfils the following needs:

Corrosion Resistance – Moulded steel grating can withstand salt water environments, helping customers avoid future replacement costs.

UV Resistance – NPG construction resins are well suited for applications exposed to sunlight and were used on this project. This grating is extremely UV resistant.

Low Installation Cost – Installed on a six-story building. These fibreglass panels can be installed easily and quickly without the use of heavy equipment or heavy machinery.

Low Maintenance Costs – The main reason they chose fibreglass reinforced plastic over aluminium was because they did not want to replace this application in the foreseeable future.

They are not willing to replace this application for the foreseeable future. Fibreglass reinforced plastic is sustainable and was the long-term solution the customer was looking for. After the installation was completed, the Foreign Trade Sales Manager followed up with the construction company. Suffice it to say, they were very pleased and found the project to be very unique and outstanding. This project would not have been possible without the combined efforts of the Tianfu New Material engineering team, and the Foreign Trade Sales Manager.